A dry oxygen thermal oxidation furnace serves as a critical processing tool designed to enhance the electrical performance of PERT solar cells through high-temperature surface treatment. Its primary function is to expose silicon wafers to a strictly controlled oxygen atmosphere, facilitating the growth of an ultra-thin, high-density silicon dioxide (SiO2) layer. This specific oxide layer acts as a passivation barrier, fundamental to the cell's ability to convert light into electricity efficiently.

The core value of this furnace lies in its ability to significantly reduce the density of dangling bonds on the silicon surface. By minimizing these defects, the process reduces surface recombination, thereby extending the minority carrier lifetime and directly increasing the overall efficiency of the solar cell.

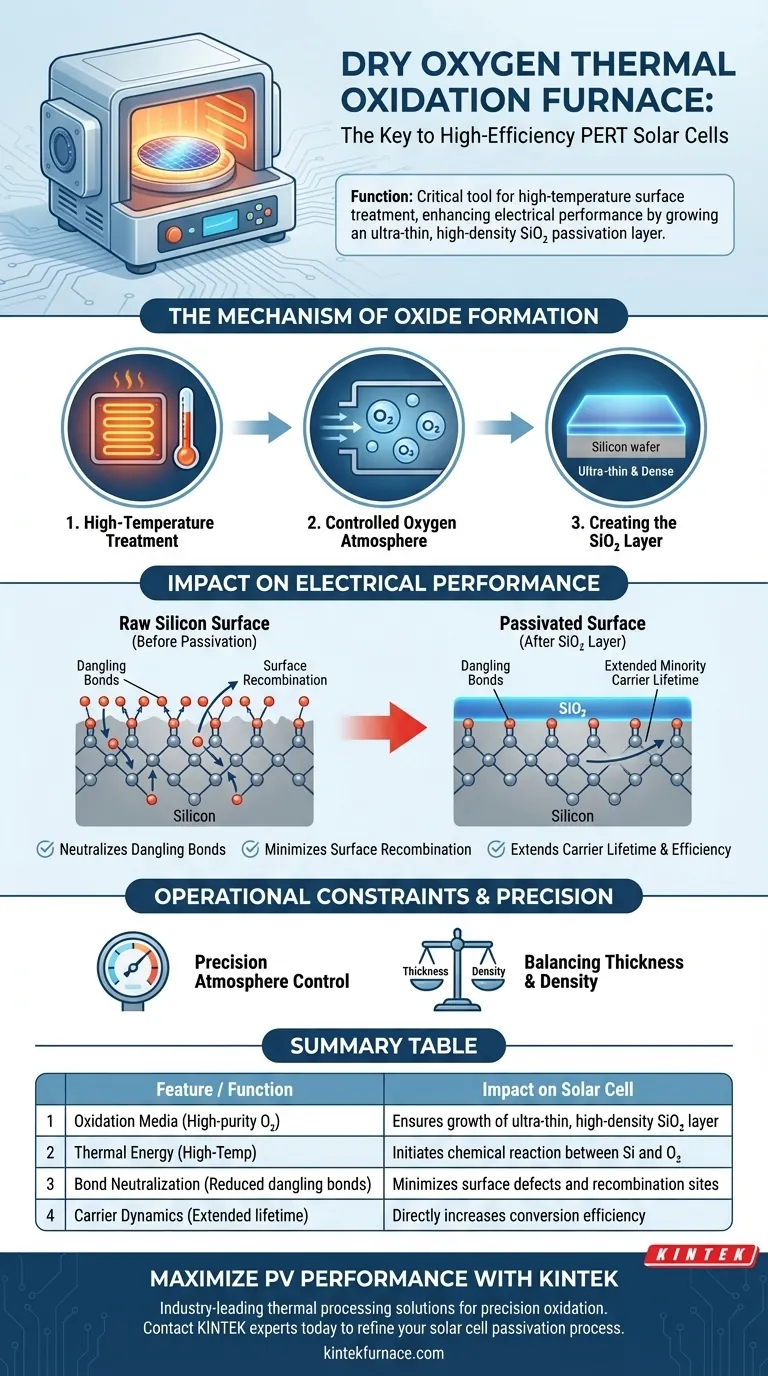

The Mechanism of Oxide Formation

High-Temperature Treatment

The furnace operates by subjecting the silicon wafers to a high-temperature treatment. This thermal energy is the catalyst required to initiate the oxidation reaction on the wafer's surface.

Controlled Oxygen Atmosphere

Crucial to this process is the environment within the furnace. It utilizes a controlled oxygen atmosphere, ensuring that pure oxygen reacts with the silicon surface in a predictable and uniform manner.

creating the SiO2 Layer

The combination of heat and oxygen results in the formation of a silicon dioxide (SiO2) passivation layer. This layer is described as ultra-thin and dense, physical characteristics that are essential for its effectiveness as an electrical barrier.

Impact on Electrical Performance

Neutralizing Dangling Bonds

A raw silicon surface is riddled with "dangling bonds"—incomplete chemical bonds that act as traps for electrical carriers. The thermal oxidation process provided by the furnace effectively reduces the density of these dangling bonds.

Minimizing Surface Recombination

By neutralizing surface defects, the SiO2 layer prevents surface recombination. This is the phenomenon where generated electrons and holes recombine and are lost before they can be collected as current.

Extending Carrier Lifetime

The direct consequence of reduced recombination is an increase in minority carrier lifetime. A longer lifetime means charge carriers exist longer within the silicon, increasing the likelihood they will contribute to the cell's power output.

Operational Constraints and Precision

The Necessity of Atmosphere Control

The effectiveness of the passivation layer relies entirely on the precision of the oxygen atmosphere. As the reference notes, the atmosphere must be "controlled" to ensure the resulting oxide layer achieves the necessary density; a fluctuating environment could compromise layer quality.

Balancing Thickness and Density

The goal is not just any oxide layer, but one that is ultra-thin and dense. The furnace must operate within specific parameters to achieve this balance, as a layer that is too porous or of incorrect thickness may fail to adequately passivate the surface defects.

Making the Right Choice for Your Goal

To maximize the benefits of dry oxygen thermal oxidation in your PERT cell production:

- If your primary focus is Cell Efficiency: Prioritize the furnace's ability to create a dense SiO2 layer, as this directly correlates to increased minority carrier lifetime.

- If your primary focus is Defect Management: Ensure the thermal treatment parameters are optimized to maximize the reduction of dangling bonds on the silicon surface.

The ultimate utility of the dry oxygen thermal oxidation furnace is its ability to turn a defect-prone silicon surface into a high-performance electrical interface.

Summary Table:

| Feature | Function in PERT Passivation | Impact on Solar Cell |

|---|---|---|

| Oxidation Media | High-purity dry oxygen atmosphere | Ensures growth of ultra-thin, high-density SiO2 layer |

| Thermal Energy | High-temperature treatment catalyst | Initiates the chemical reaction between Si and O2 |

| Bond Neutralization | Reducing dangling bond density | Minimizes surface defects and recombination sites |

| Carrier Dynamics | Extending minority carrier lifetime | Directly increases the conversion efficiency of the cell |

Maximize Your Photovoltaic Performance with KINTEK

Ready to elevate your PERT solar cell efficiency? KINTEK provides industry-leading high-temperature thermal processing solutions tailored for precision oxidation. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific lab or production requirements.

Our thermal oxidation furnaces ensure the perfect balance of oxide density and thickness to minimize surface recombination and maximize carrier lifetime. Contact KINTEK experts today to discuss your unique needs and discover how our advanced furnace technology can refine your solar cell passivation process.

Visual Guide

References

- Hakim Korichi, Ahmed Baha-Eddine Bensdira. Investigating the influence of boron diffusion temperature on the performance of n-type PERT monofacial solar cells with reduced thermal steps. DOI: 10.35784/iapgos.6599

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a vertical vacuum furnace in the purification of Rubidium Chloride? Achieve High Purity Yields

- What are the key characteristics of high-temperature vacuum furnaces? Achieve Ultimate Purity and Precision in Material Processing

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- How do drop-bottom quench furnaces compare to other furnace types? Discover Their Speed and Precision Advantages

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- Why must ESL density measurements of refractory metals use high vacuum systems? Ensure Precision at 3000 K+

- How does a heat treatment furnace modify Fe-Cu composites? Enhancing Strength and Toughness via Precision Thermal Cycles

- What are the advantages of using heat treatment and vacuum furnaces? Achieve Superior Material Quality and Control