Precise thermal regulation is the mechanism by which a heat treatment furnace alters the internal structure of Iron-Copper (Fe-Cu) composites. By strictly controlling heating temperatures and holding times, the furnace drives phase transformations specifically within the iron skeleton, converting it into harder, more durable crystalline forms while leaving the conductive copper network intact.

The core objective is to transform the iron matrix from a base state into high-strength martensite via quenching, and then stabilize it into tough tempered sorbite via tempering. This two-step process significantly boosts mechanical performance without compromising the composite's conductivity.

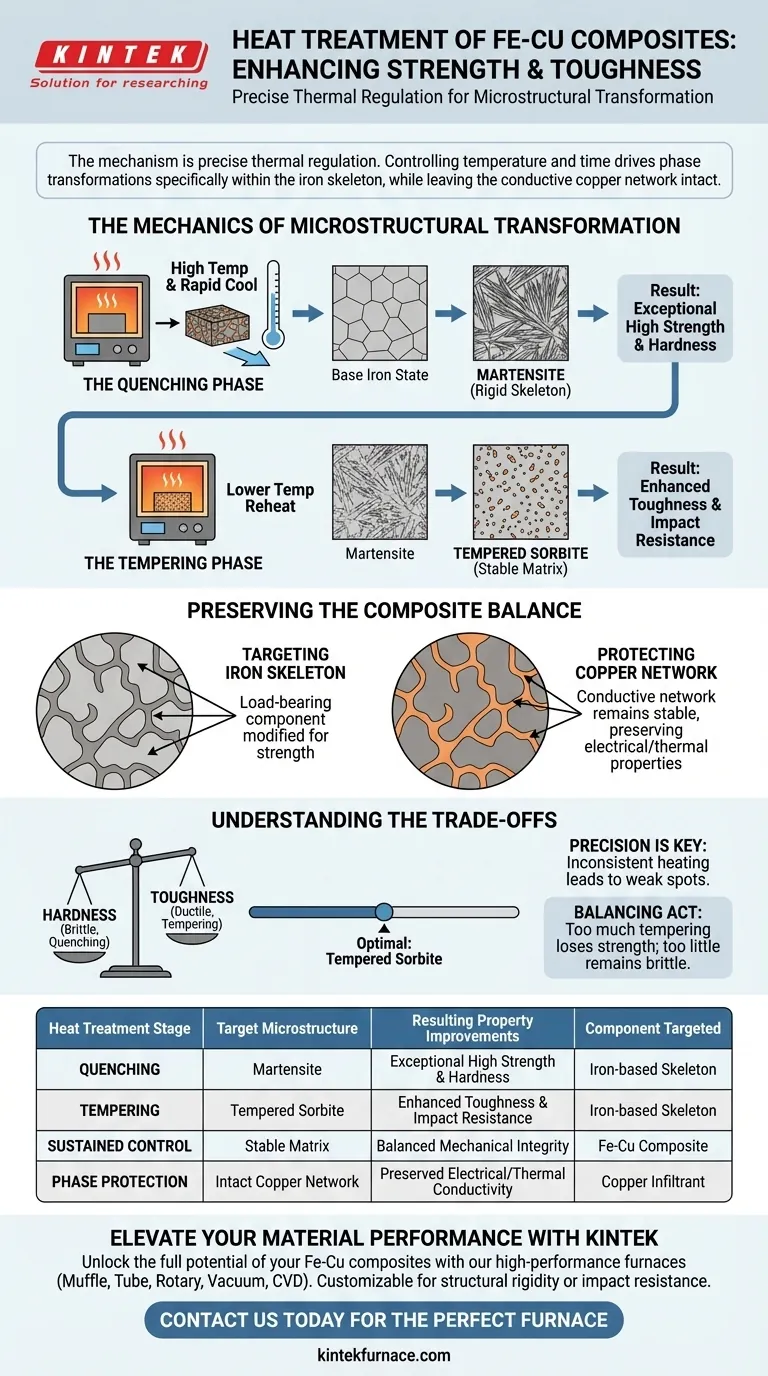

The Mechanics of Microstructural Transformation

The Quenching Phase

The first stage of the process involves heating the composite and then cooling it rapidly. This induces a dramatic phase change in the iron matrix.

The primary goal here is to transform the iron into martensite. Martensite is a supersaturated solid solution that provides the composite with exceptional high strength and hardness, forming a rigid skeleton.

The Tempering Phase

Following quenching, the material undergoes tempering, which involves reheating to a specific, lower temperature. This step is critical because pure martensite, while strong, can be brittle.

Tempering transforms the martensite into tempered sorbite. This microstructure creates a more stable matrix that retains high strength but gains significant toughness, allowing the material to withstand impact without fracturing.

Preserving the Composite Balance

Targeting the Iron Skeleton

The heat treatment furnace focuses its energy on the iron-based skeleton. The iron acts as the load-bearing component of the composite, and modifying its microstructure is the primary method for enhancing mechanical properties.

Protecting the Copper Network

A critical aspect of this process is that it enhances the iron matrix without disrupting the conductive copper network.

Because copper has different thermal properties and phase transition points, the specific temperatures used for treating iron allow the copper to remain stable. This ensures that while the material becomes stronger physically, it retains its essential electrical or thermal conductivity.

Understanding the Trade-offs

The Necessity of Precision

The effectiveness of this process relies entirely on precise control of temperature and time. If the heating is inconsistent, the phase transformation to martensite may be incomplete, resulting in weak spots within the composite.

Balancing Hardness and Ductility

There is an inherent trade-off between the hardness achieved during quenching and the toughness gained during tempering.

If the tempering process is cut short, the material may remain too brittle (too much martensite). Conversely, if held too long or too hot, the material may lose too much strength in favor of ductility. The furnace must maintain a strict regimen to achieve the optimal tempered sorbite state.

Making the Right Choice for Your Goal

To maximize the utility of Fe-Cu composites, you must tune the furnace parameters to your specific mechanical requirements.

- If your primary focus is Maximum Structural Rigidity: Prioritize the efficiency of the quenching phase to ensure a complete transformation to martensite before tempering.

- If your primary focus is Impact Resistance (Toughness): Ensure the tempering stage is sufficiently long to fully convert brittle phases into stable tempered sorbite.

By mastering these thermal cycles, you evolve the composite from a simple mixture into a sophisticated, high-performance material.

Summary Table:

| Heat Treatment Stage | Target Microstructure | Resulting Property Improvements | Component Targeted |

|---|---|---|---|

| Quenching | Martensite | Exceptional High Strength & Hardness | Iron-based Skeleton |

| Tempering | Tempered Sorbite | Enhanced Toughness & Impact Resistance | Iron-based Skeleton |

| Sustained Control | Stable Matrix | Balanced Mechanical Integrity | Fe-Cu Composite |

| Phase Protection | Intact Copper Network | Preserved Electrical/Thermal Conductivity | Copper Infiltrant |

Elevate Your Material Performance with KINTEK

Unlock the full potential of your Fe-Cu composites with the precision thermal control required for complex phase transformations. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are targeting structural rigidity or impact resistance, our lab high-temp furnaces are fully customizable to meet your unique metallurgical needs.

Ready to optimize your heat treatment process? Contact us today to speak with a specialist and find the perfect furnace for your laboratory.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What temperature is vacuum brazing? Achieve Strong, Flux-Free Joints in a Controlled Environment

- How does vacuum carburizing improve operational efficiency? Boost Speed, Quality, and Cost Savings

- How do multi-chamber designs improve energy efficiency? Cut Costs with Continuous Thermal Processing

- What are the advantages of using a vacuum heat treatment furnace? Achieve Superior Material Quality and Control

- What role does a vacuum heat treatment furnace play in the preparation of SKD6 side dies? Enhance Tool Steel Longevity

- Why is a vacuum high-temperature furnace necessary for Cu-Cr-Zr-La alloy ingots? Ensure Material Uniformity

- What is the core technical mechanism of low-oxygen brazing? Master Oxide Decomposition for Perfect Bonds

- What is the significance of high-temperature vacuum drying systems for regenerating dehydration materials? Boost Efficiency