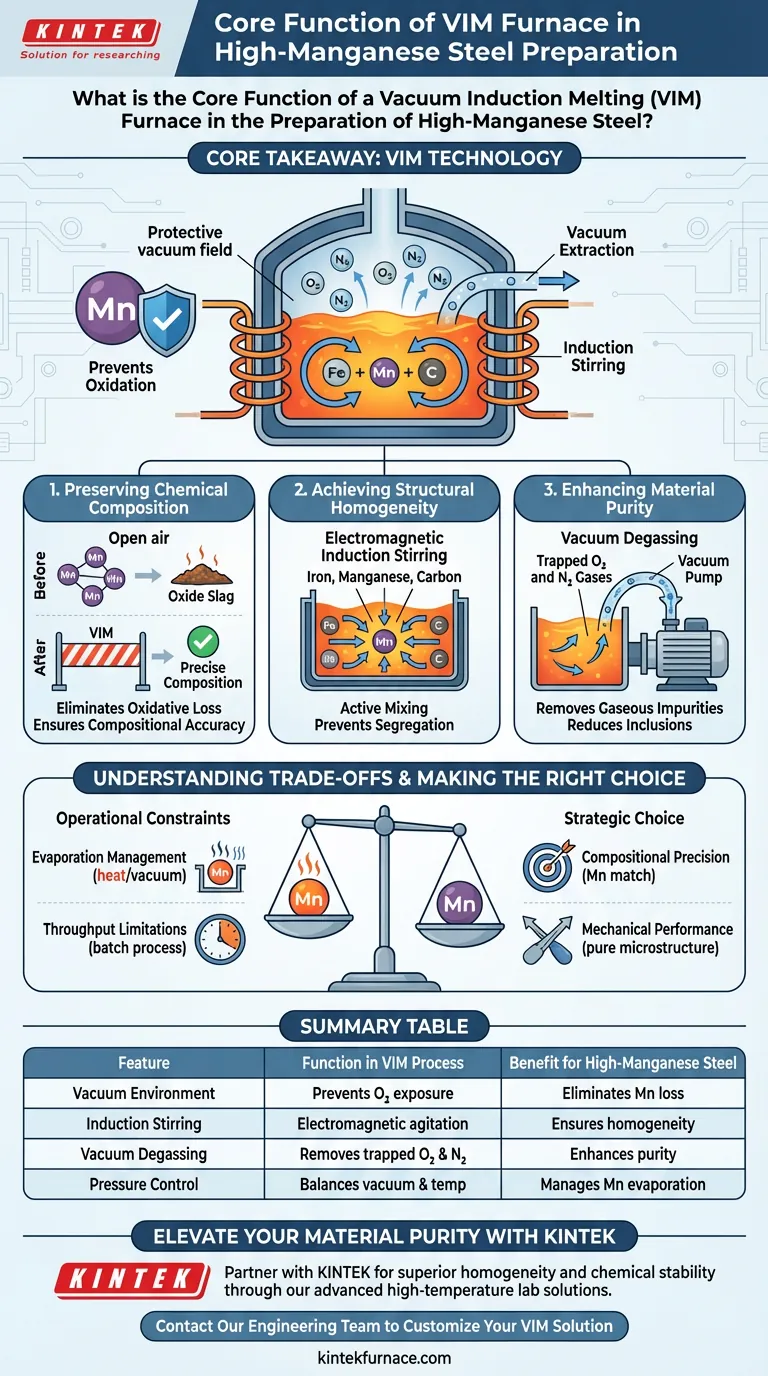

The core function of a Vacuum Induction Melting (VIM) furnace is to create a strictly controlled, low-pressure environment that safeguards the precise chemical stability of high-manganese steel. By isolating the molten metal from the atmosphere, the furnace prevents the rapid oxidative loss of reactive manganese, while simultaneously utilizing induction currents to physically mix the alloy and remove harmful gases.

Core Takeaway: VIM technology addresses the unique instability of manganese by eliminating atmospheric exposure to prevent oxidation, while leveraging electromagnetic stirring to ensure a homogeneous alloy and vacuum pressure to extract gaseous impurities like oxygen and nitrogen.

Preserving Chemical Composition

The primary challenge in synthesizing high-manganese steel is the element's high reactivity. Without protection, manganese rapidly degrades when exposed to oxygen at melting temperatures.

Preventing Oxidative Loss

Manganese is an "active" alloying element that reacts aggressively with atmospheric oxygen. The VIM furnace creates a vacuum environment that eliminates this exposure entirely.

By removing oxygen from the melting chamber, the furnace ensures that the manganese remains in the steel rather than being lost as oxide slag. This allows for precise control over the final alloy composition.

Ensuring Compositional Accuracy

High-performance steel requires exact ratios of elements. The VIM process guarantees that the formulated amount of manganese added to the melt is exactly what ends up in the final product.

Achieving Structural Homogeneity

Preserving the element is only the first step; distributing it evenly throughout the iron matrix is equally critical for material performance.

Electromagnetic Induction Stirring

The VIM furnace does not merely heat the metal; it agitates it. The induction currents used to melt the steel generate strong electromagnetic forces within the molten pool.

This automatic stirring effect rigorously mixes the iron, manganese, and carbon.

Eliminating Segregation

Without this active mixing, alloying elements could clump or separate, leading to weak spots in the final material. The continuous movement ensures the chemical composition is uniform from the core to the surface of the ingot.

Enhancing Material Purity

Beyond mixing the intended elements, the VIM furnace is essential for actively removing unintended contaminants.

Vacuum Degassing

Molten steel naturally traps harmful gases, specifically oxygen and nitrogen, which can cause brittleness or porosity.

The low-pressure environment of the VIM furnace forces these gases out of the solution and evacuates them from the chamber.

Reducing Inclusions

By stripping away these gaseous impurities, the furnace significantly enhances the overall purity of the steel. This results in a cleaner microstructure free from gas-based defects that could compromise structural integrity.

Understanding the Trade-offs

While VIM is the superior method for high-manganese steel, it introduces specific operational constraints that must be managed.

Evaporation Management

While the vacuum prevents oxidation, the low pressure combined with high heat can theoretically lead to the evaporation of volatile elements like manganese.

Operators must precisely balance vacuum levels and temperature to prevent the manganese from vaporizing, rather than just oxidizing.

Throughput Limitations

VIM is a batch process that is inherently slower and more complex than open-air induction melting. It prioritizes quality and precision over the high-volume speed found in standard steel production.

Making the Right Choice for Your Goal

The use of a VIM furnace is a strategic choice driven by the specific requirements of your end-product.

- If your primary focus is Compositional Precision: The VIM furnace is non-negotiable for preventing the oxidative loss of active elements like manganese to ensure the alloy matches the exact chemical recipe.

- If your primary focus is Mechanical Performance: The vacuum degassing and electromagnetic stirring capabilities are essential for creating a high-purity, inclusion-free microstructure that offers superior strength and ductility.

Success in preparing high-manganese steel relies on using VIM not just as a heater, but as a precision tool to stabilize, homogenize, and purify the melt.

Summary Table:

| Feature | Function in VIM Process | Benefit for High-Manganese Steel |

|---|---|---|

| Vacuum Environment | Prevents atmospheric oxygen exposure | Eliminates oxidative loss of reactive manganese |

| Induction Stirring | Electromagnetic agitation of melt | Ensures structural homogeneity and prevents segregation |

| Vacuum Degassing | Removes trapped O2 and N2 gases | Enhances purity and eliminates gas-based defects |

| Pressure Control | Balances vacuum and temperature | Manages manganese evaporation while maintaining stability |

Elevate Your Material Purity with KINTEK

Precise alloy composition is the foundation of high-performance materials. At KINTEK, we understand that high-manganese steel demands uncompromising control. Backed by expert R&D and manufacturing, we offer Vacuum Induction Melting (VIM) systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to meet your unique metallurgical needs.

Don't let oxidation or inclusions compromise your results. Partner with KINTEK to achieve superior homogeneity and chemical stability through our advanced high-temperature lab solutions.

Contact our engineering team today to customize your VIM solution.

Visual Guide

References

- Lu, Shao-Lun, Max-Planck-Institut für Nachhaltige Materialien. Making High Mn Steel by Sustainable Ferromanganese Pre-alloy for Cryogenic Applications. DOI: 10.5281/zenodo.17520991

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What role does the vacuum chamber play in the melting process? Enhance Metal Purity and Efficiency

- Why are higher frequencies needed in coreless induction furnaces for melting small loads of gold? Achieve Efficient Melting for Jewelry and Lab Samples

- What are the efficiency benefits of IGBT modules in melting machines? Achieve Faster Melting & Superior Quality

- What role does a vacuum induction melting furnace play in CoCrFeMnNi production? Ensure Purity and Homogeneity

- What is the function of a non-consumable vacuum arc furnace for CoCrFeNiZr0.3 alloys? High-Purity Melting Solutions

- Which industries commonly use vacuum casting furnaces and for what applications? Discover Key Uses in Aerospace, Medical, and More

- What is the primary function of a mechanical stirrer in stir casting? Master Al2214 Hybrid Composite Uniformity

- What are the advantages and uses of induction furnaces in foundries? Achieve Fast, Clean, and Precise Metal Melting