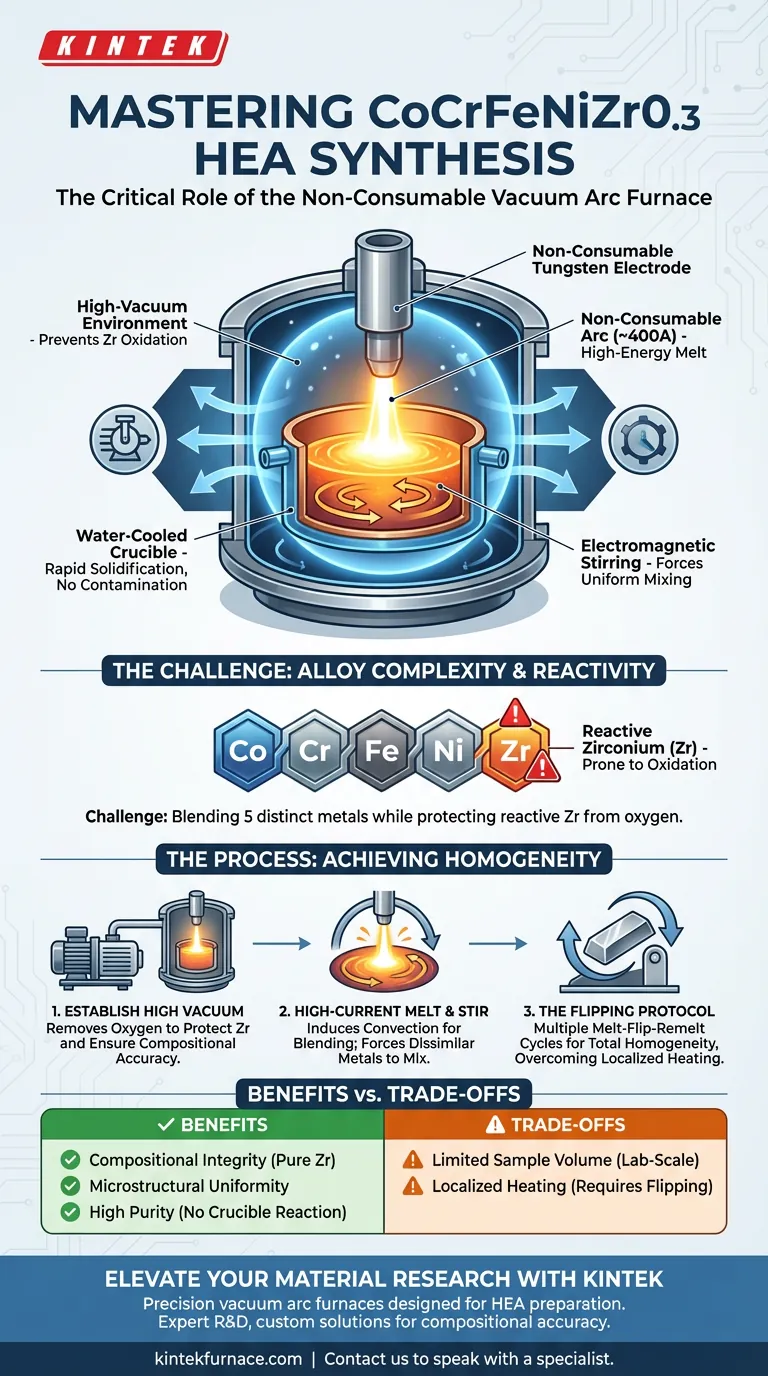

The critical function of a non-consumable vacuum arc furnace in this context is to provide a high-purity, high-energy environment that simultaneously melts complex components and protects reactive elements. Specifically, it prevents the oxidation of Zirconium (Zr) while ensuring the thorough mixing of Cobalt, Chromium, Iron, and Nickel into a single, uniform solid solution.

Core Takeaway The preparation of CoCrFeNiZr0.3 relies on overcoming two main obstacles: the high reactivity of Zirconium and the difficulty of blending five distinct metals. The non-consumable vacuum arc furnace solves this by maintaining a strict vacuum to eliminate oxygen and utilizing high-current electromagnetic stirring to force compositional uniformity.

Prevention of Elemental Oxidation

The most immediate risk in preparing CoCrFeNiZr0.3 is the chemical nature of Zirconium.

The Vulnerability of Zirconium

Zirconium (Zr) is classified as an active element. At the high temperatures required to melt transition metals like Chromium and Iron, Zr readily reacts with oxygen in the atmosphere.

The High-Vacuum Solution

The furnace operates in a high-vacuum environment. By evacuating the chamber, the system removes oxygen that would otherwise bond with the Zirconium.

Preserving Compositional Accuracy

If oxidation occurs, the Zr content in the final alloy would drop below the target 0.3 molar ratio, and oxide inclusions would contaminate the material. The vacuum ensures the final ingot matches the designed chemical composition.

Ensuring Homogeneity in High-Entropy Alloys

High-entropy alloys (HEAs) derive their properties from the precise mixing of multiple principal elements. Achieving a uniform distribution is mechanically difficult but essential.

Generating a Stable Arc

The furnace utilizes a non-consumable electrode (typically tungsten) to generate an electric arc. This arc is sustained by a high current, often around 400 A, providing the intense, localized heat necessary to rapidly melt high-melting-point elements like Chromium.

Electromagnetic Stirring

Beyond simple heating, the high current flowing through the melt pool interacts with magnetic fields to induce electromagnetic stirring. This natural convection forces the heavier and lighter elements to mix continuously, preventing them from separating based on density.

The Flipping Protocol

To further guarantee uniformity, the process involves multiple flipping cycles. The ingot is melted, allowed to solidify, mechanically flipped over, and remelted. This ensures that material at the bottom of the water-cooled crucible is mixed just as thoroughly as the material at the top.

Understanding the Trade-offs

While the vacuum arc furnace is the standard for high-purity lab-scale synthesis, it has inherent limitations you must account for.

Limited Sample Volume

These furnaces typically utilize a water-cooled copper crucible, which is excellent for rapid solidification and preventing contamination from crucible materials. However, this restricts the volume of the melt, making it suitable primarily for small-scale ingots rather than mass production.

Localized Heating

The heat source is a localized arc. Unlike induction melting which heats the entire volume simultaneously, the arc heats from the top down. This makes the flipping and remelting steps non-negotiable; skipping them will almost certainly result in a chemically segregated ingot.

Making the Right Choice for Your Goal

This equipment is a precision tool designed for specific metallurgical requirements.

- If your primary focus is compositional integrity: The vacuum environment is non-negotiable to prevent Zirconium loss and oxide contamination.

- If your primary focus is microstructural uniformity: You must adhere to a strict protocol of high-current melting (e.g., 400 A) combined with multiple flipping cycles to utilize the electromagnetic stirring effect fully.

The non-consumable vacuum arc furnace is not just a heat source; it is a containment system that forces dissimilar, reactive elements to coexist as a unified high-performance alloy.

Summary Table:

| Feature | Function in CoCrFeNiZr0.3 Preparation | Benefit |

|---|---|---|

| High Vacuum | Eliminates oxygen from the melting chamber | Prevents oxidation of active Zirconium (Zr) |

| Non-Consumable Arc | Provides localized heat at high currents (e.g., 400A) | Rapidly melts high-melting-point elements like Cr |

| Electromagnetic Stirring | Induces convection within the melt pool | Forces uniform mixing of 5+ dissimilar metals |

| Water-Cooled Crucible | Rapid solidification without crucible reaction | Ensures high purity and prevents contamination |

| Flipping Protocol | Repeating melting cycles (flipping the ingot) | Eliminates chemical segregation for total homogeneity |

Elevate Your Material Research with KINTEK

Precision alloy synthesis requires equipment that can handle reactive elements and complex compositions without compromise. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, including high-performance vacuum arc furnaces designed for the rigorous demands of high-entropy alloy (HEA) preparation.

Whether you need customized laboratory high-temperature furnaces or specialized melting systems, our technology ensures compositional accuracy and microstructural uniformity for your unique research needs.

Ready to optimize your melting process? Contact us today to speak with a specialist.

Visual Guide

References

- Peng Lyu, Xinlin Liu. Hot Deformation Characteristics and Microstructure Evolution of CoCrFeNiZr0.3 Hypoeutectic High-Entropy Alloy. DOI: 10.3390/met14060632

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the primary role of vacuum induction melting equipment in the preparation of NiTi alloys? Ensure Nitinol Purity

- What are the main benefits of using an induction furnace for gold melting compared to traditional furnaces? Discover Faster, Purer Melts

- What is the primary purpose of using induction furnaces under vacuum or protective atmospheres? Achieve Purity and Performance in High-Performance Alloys

- What essential conditions does a crucible melting furnace provide for Al-Si alloys? Master Your Casting Precision

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is the coreless induction furnace used for in the metal thermal processing industry? Achieve Clean, Efficient Metal Melting

- What advanced control features does the IGBT induction melting furnace offer? Intelligent, Self-Regulating Control for Peak Efficiency

- Why is a non-consumable vacuum arc melting furnace used for AlCrTiVNbx alloys? Ensure Purity & Homogeneity