For high-performance alloys, the primary purpose of using an induction furnace under a vacuum or protective atmosphere is to control the material's chemistry at a fundamental level. This controlled environment prevents the molten metal from reacting with atmospheric gases like oxygen, nitrogen, and hydrogen, which would otherwise introduce impurities that degrade the final product's structural integrity and performance.

Controlling the furnace atmosphere is not merely a protective measure; it is an essential manufacturing step for creating advanced materials. It is the deliberate choice to eliminate unwanted chemical reactions to achieve unparalleled purity and predictable, high-performance mechanical properties.

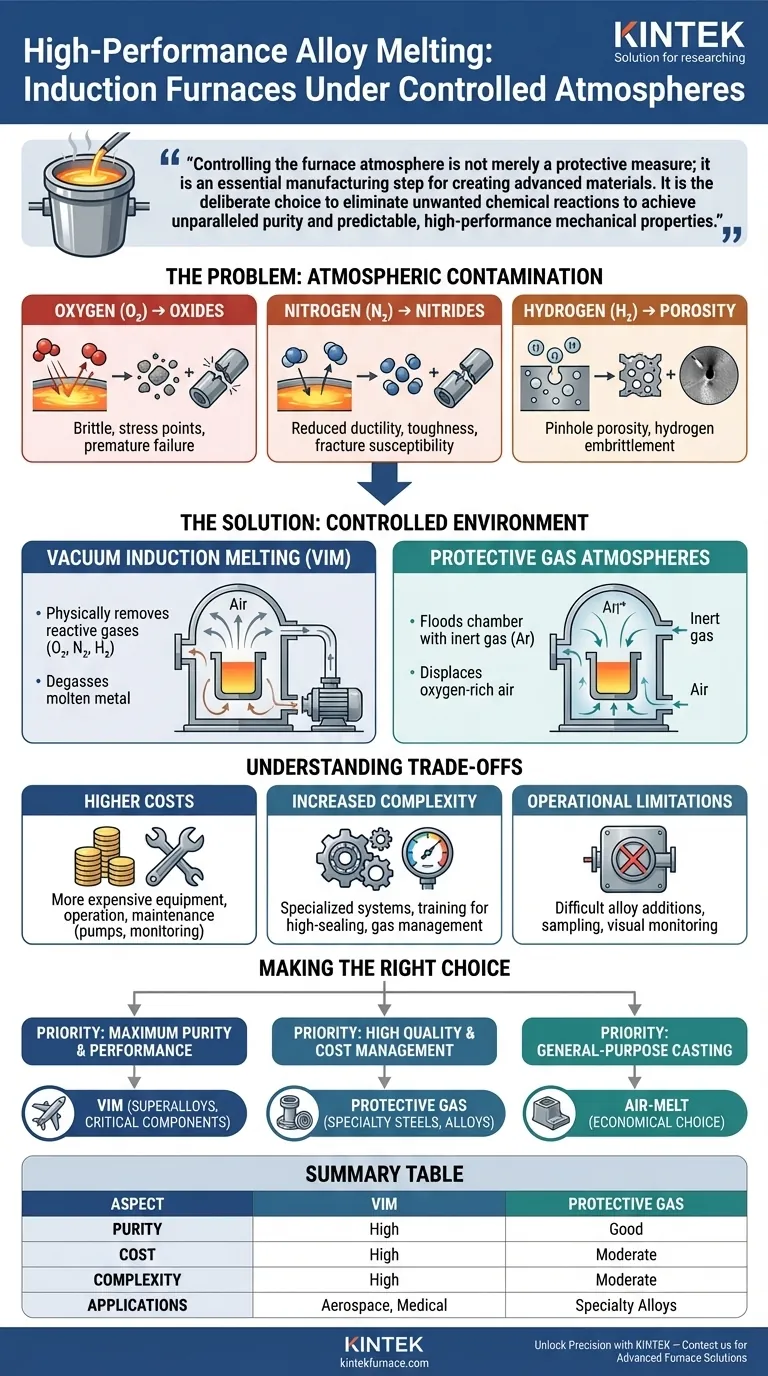

The Problem: Atmospheric Contamination in Molten Metal

At high temperatures, molten metal is extremely reactive. Exposing it to ambient air invites a host of chemical reactions that are detrimental to the quality of the final cast component.

The Role of Oxygen: Formation of Oxides

Oxygen in the air readily reacts with most molten metals to form oxide inclusions. These non-metallic particles are often brittle and act as internal stress concentration points, creating microscopic weak spots that can initiate cracks and lead to premature material failure.

The Impact of Nitrogen: Unwanted Nitrides

Similarly, nitrogen can dissolve into the molten bath and form hard, brittle nitride particles in certain alloys. These inclusions reduce the material's ductility and toughness, making it more susceptible to fracture under load.

The Threat of Hydrogen: Porosity and Embrittlement

Hydrogen, often from moisture in the atmosphere, is highly soluble in molten metal but its solubility drops dramatically as the metal solidifies. This forces the trapped hydrogen out of solution, creating tiny gas bubbles known as pinhole porosity. This porosity weakens the entire structure and can also lead to a phenomenon called hydrogen embrittlement.

The Solution: Controlling the Furnace Environment

To combat these issues, specialized induction furnaces isolate the melt from the ambient atmosphere in one of two primary ways.

Vacuum Induction Melting (VIM)

The most effective method is to place the entire induction coil and crucible inside a chamber and pull a strong vacuum. This physically removes the reactive gases, preventing oxides and nitrides from forming. It also helps to degas the molten metal itself, pulling out dissolved hydrogen to prevent porosity.

Protective Gas Atmospheres

A more common and cost-effective alternative is to purge the melt chamber with a protective atmosphere. This involves flooding the area with an inert gas, like argon, which displaces the oxygen-rich air. For some processes, a reactive gas like nitrogen or a reducing atmosphere may be used intentionally to achieve specific metallurgical properties.

Understanding the Trade-offs

While essential for high-quality materials, operating under a vacuum or controlled atmosphere introduces significant challenges and costs.

Higher Equipment and Operational Costs

Vacuum induction furnaces are substantially more expensive to purchase, operate, and maintain than their air-melt counterparts due to the need for vacuum chambers, pumps, and sophisticated monitoring systems.

Increased System Complexity

The high-sealing requirements of a vacuum chamber and the complex systems needed to manage gas flow and pressure add layers of operational complexity. This demands specialized training for operators and maintenance staff.

Operational Limitations

The sealed environment makes it more difficult to add alloy materials, take samples, or visually monitor the melt. Every intervention risks compromising the integrity of the vacuum or protective atmosphere.

Making the Right Choice for Your Application

Selecting the right furnace environment depends entirely on the required properties of the final material and the project's budget.

- If your primary focus is maximum purity and performance: A Vacuum Induction Melting (VIM) system is non-negotiable for producing superalloys, medical implants, or critical aerospace components.

- If your primary focus is high quality while managing costs: Melting under a protective inert gas (like argon) provides excellent protection from oxidation and is a major improvement over air melting for many specialty steels and alloys.

- If your primary focus is general-purpose casting: For applications where the presence of some oxides does not compromise performance, a standard air-melt induction furnace remains the most economical choice.

By actively controlling the furnace environment, you move from simply melting metal to precisely engineering a material's final properties from its liquid state.

Summary Table:

| Aspect | Vacuum Induction Melting (VIM) | Protective Gas Atmospheres |

|---|---|---|

| Purpose | Remove reactive gases via vacuum to prevent oxides, nitrides, and degas hydrogen | Displace air with inert gases like argon to protect from oxidation and contamination |

| Benefits | Maximum purity, ideal for superalloys, medical implants, aerospace | Cost-effective, high-quality protection for specialty steels and alloys |

| Challenges | High equipment cost, operational complexity, limited melt monitoring | Moderate cost, requires gas management, less purity than VIM |

Unlock Precision in Your Material Engineering with KINTEK

Are you developing high-performance alloys for aerospace, medical, or specialty applications? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Ensure unparalleled purity and predictable mechanical properties in your materials—contact us today to discuss how our solutions can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the primary industrial applications of induction furnaces? Unlock Efficient Metal Processing Solutions

- Why are induction gold melting furnaces considered cost-effective in the long run? A Smart Investment for Higher Profits

- What industries commonly use induction-heated vacuum furnaces? Unlock High-Purity, High-Performance Material Processing

- How does IGBT technology increase melting capacity and productivity? Unlock Faster Melts and Higher Output

- Why Use an Argon Arc Melting Furnace for MnCoNiCuGe5 Alloys? Ensuring Purity in High-Entropy Brazing

- What role does a crucible lid play during the vacuum induction smelting of AlV55 alloys? Boost Purity & Yield

- What are the advantages of induction melting furnaces in metal processing? Boost Efficiency, Quality, and Safety

- What future advancements are expected in vacuum or protective atmosphere melting technology? Discover AI-Driven Precision and Efficiency