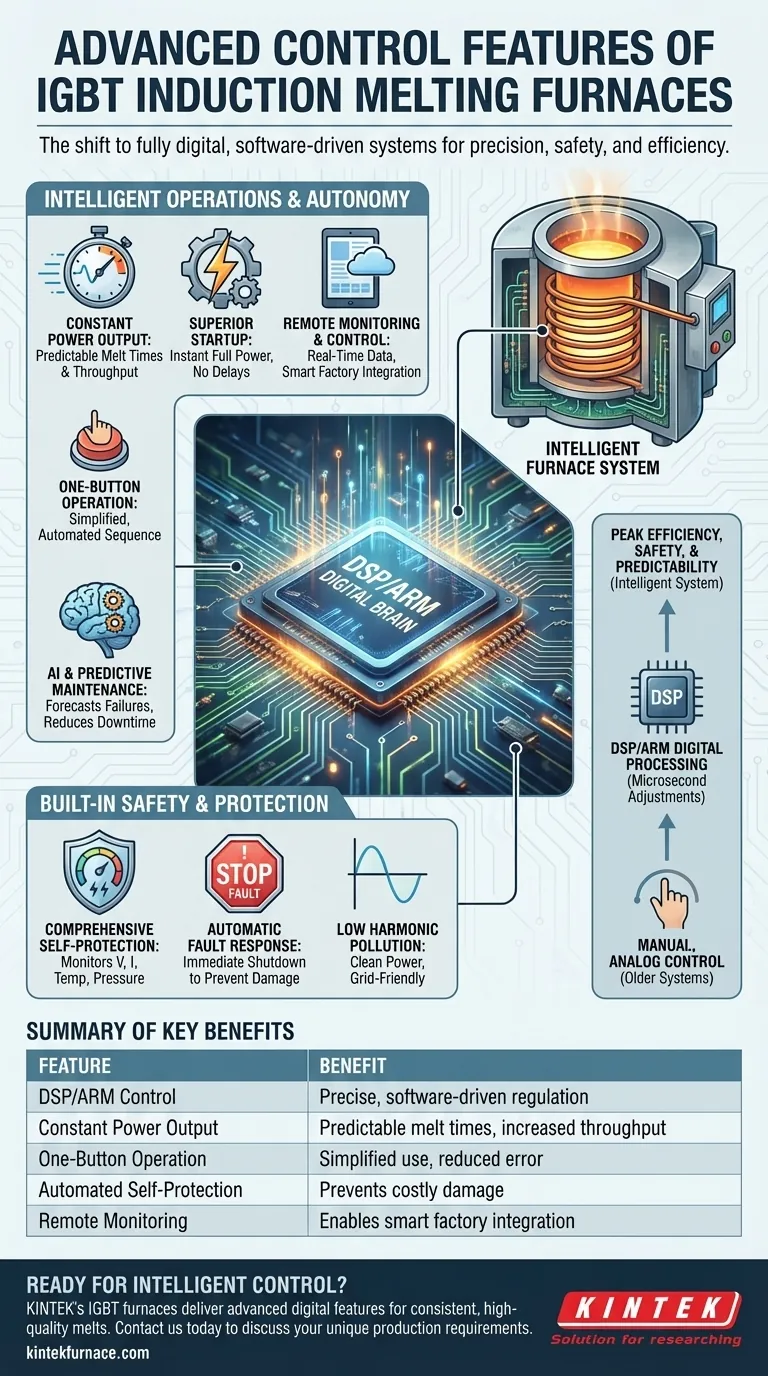

At their core, IGBT induction melting furnaces offer advanced control through a fully digital, software-driven system. This is typically managed by a DSP or ARM processor, which enables precise power regulation, constant power output regardless of conditions, and a suite of automated self-protection functions. These features are augmented by modern communication interfaces for remote monitoring and control.

The key advancement is the shift from a manually-tuned heating appliance to an intelligent, self-regulating system. This digital brain ensures the furnace operates at peak efficiency, safety, and predictability with minimal operator intervention, directly impacting melt times, energy costs, and equipment lifespan.

The Core of Control: The Digital Brain

The defining feature of a modern IGBT furnace is its departure from older, analog-based control methods. This digital foundation enables a level of precision and automation that was previously unattainable.

DSP/ARM-Based Digital Processing

At the heart of the furnace is a high-speed Digital Signal Processor (DSP) or ARM-based embedded controller. This acts as the system's brain.

Instead of relying on simple analog circuits, this processor runs sophisticated software algorithms. It constantly monitors electrical parameters and makes microsecond adjustments to maintain optimal performance, much like a modern car's engine control unit (ECU).

Constant Power Output

A critical control feature is the ability to maintain constant power output throughout the entire melting process.

In older systems, power could fluctuate as the furnace lining wore down or as the physical state of the metal changed. An IGBT system's digital controller automatically compensates for these changes, ensuring a consistent energy delivery. This results in highly predictable melt times and increased throughput, particularly for materials like stainless steel, copper, and aluminum.

Superior Startup Performance

The series resonant circuit design, managed by the IGBT controller, provides excellent startup performance.

This eliminates the starting difficulties common in older SCR (silicon-controlled rectifier) furnaces. The furnace can achieve full power nearly instantaneously, reducing wasted time and energy at the beginning of each cycle.

Intelligent Operations and System Autonomy

Advanced control extends beyond just melting metal. It encompasses how the operator interacts with the machine and how the furnace integrates into the broader facility.

Real-Time Monitoring and Remote Control

Equipped with rich communication interfaces, these furnaces are built for the modern factory. This allows for full remote control and real-time data monitoring.

Operators can track melt progress, energy consumption, and system status from a central control room or even a mobile device. This data is invaluable for process optimization and integrating the furnace into a larger manufacturing execution system (MES).

Simplified "One-Button" Operation

The complexity of the internal control system enables radical simplicity for the operator. Many functions are automated, allowing for a "one-button" start-up and operational sequence.

The system manages the power ramp-up, temperature holds, and fault monitoring automatically. This reduces the need for highly specialized operators and minimizes the chance of human error.

The Future: AI and Predictive Maintenance

The most advanced systems are integrating Artificial Intelligence (AI) and machine learning.

By analyzing historical performance data, the furnace can begin to predict when a component is likely to fail. This enables predictive maintenance, allowing service to be scheduled before a critical failure occurs, which dramatically reduces unplanned downtime and catastrophic damage.

Built-in Safety and Protection Mechanisms

A primary role of the advanced control system is to protect the equipment and the personnel operating it. It acts as a vigilant, always-on supervisor.

Comprehensive Self-Protection

The furnace's controller constantly monitors a wide range of parameters, including voltage, current, water temperature, and water pressure. It includes perfect self-protection functions for events like over-voltage, over-current, and phase loss.

Automatic Fault Response

When the system detects a problem, it doesn't just raise an alarm—it takes immediate, corrective action.

For example, if it detects a cooling water issue, it can automatically shut down power to prevent the IGBT modules and induction coil from overheating and failing. This proactive response is crucial for preventing costly damage.

Low Harmonic Pollution

A significant benefit of the IGBT power control topology is its minimal harmonic pollution.

Unlike older power supplies, it does not distort the factory's electrical grid. This prevents interference with other sensitive electronic equipment and helps the facility avoid potential penalties from the power utility for poor power factor.

Making the Right Choice for Your Operation

Understanding these features allows you to align the technology with your specific production goals.

- If your primary focus is throughput and efficiency: The constant power output and fast startup capabilities ensure the most predictable and rapid melt cycles.

- If your primary focus is process consistency: The precise digital control maintains stable parameters, leading to highly repeatable metallurgical quality from one batch to the next.

- If your primary focus is modernization and data integration: The remote monitoring and AI-readiness allow the furnace to become a key data-producing asset in a smart factory environment.

- If your primary focus is safety and reliability: The extensive, automated self-protection and fault response systems provide an unparalleled safeguard for both your equipment and personnel.

Ultimately, these advanced control features transform the furnace from a simple melting tool into an intelligent, self-regulating asset for your entire operation.

Summary Table:

| Feature | Key Benefit |

|---|---|

| DSP/ARM Digital Control | Precise, software-driven power regulation |

| Constant Power Output | Predictable melt times and increased throughput |

| One-Button Operation | Simplified use and reduced operator error |

| Automated Self-Protection | Prevents costly damage from faults |

| Remote Monitoring & Control | Enables integration into smart factory systems |

Ready to transform your metal melting operation with intelligent control?

KINTEK's IGBT induction melting furnaces leverage our exceptional R&D and in-house manufacturing to deliver the advanced digital features detailed above. Our solutions provide the precise control, efficiency, and reliability needed for consistent, high-quality melts of materials like stainless steel, copper, and aluminum.

Contact KINTEK today to discuss how our advanced furnace technology and deep customization capabilities can precisely meet your unique production requirements.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control