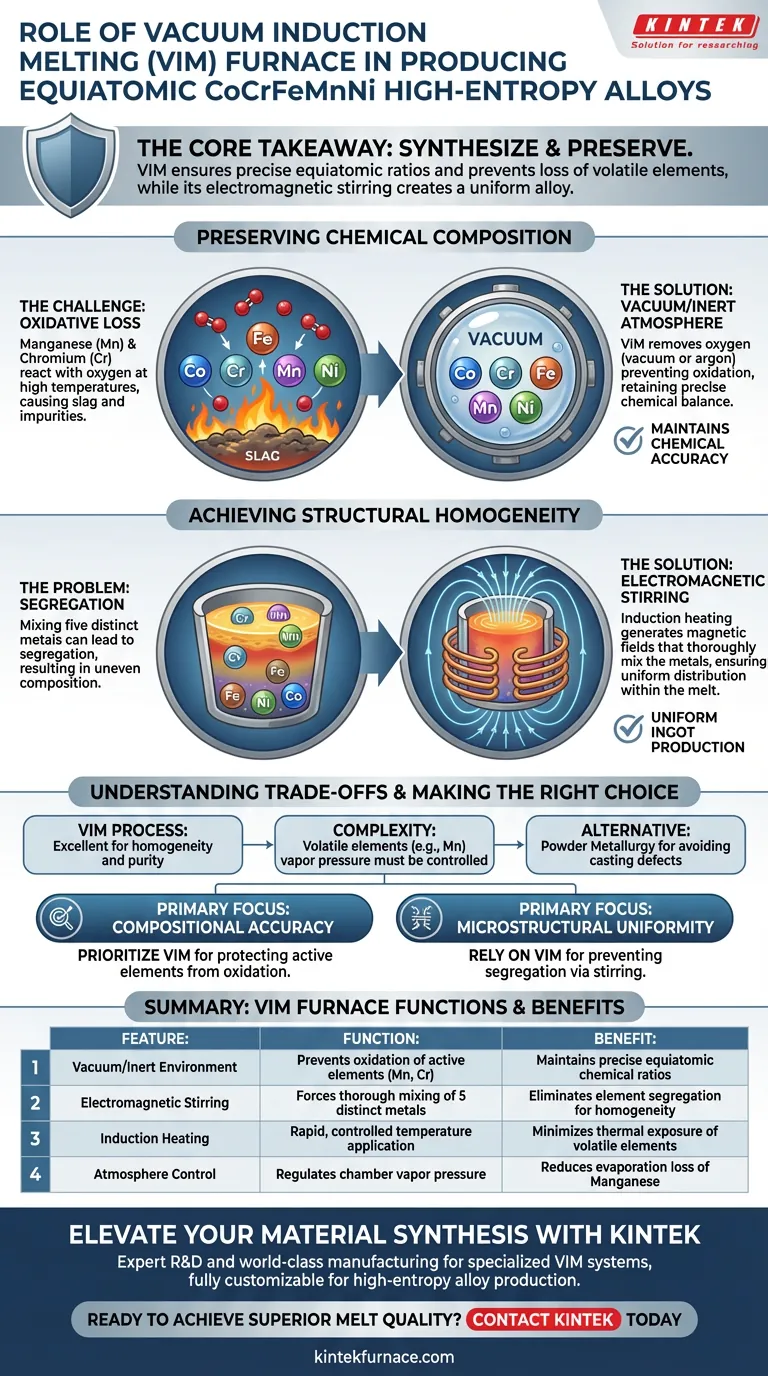

A vacuum induction melting (VIM) furnace serves as the critical processing vessel for ensuring the chemical accuracy and structural integrity of equiatomic CoCrFeMnNi high-entropy alloys. Its primary function is to create a protective environment that prevents the loss of volatile elements while simultaneously utilizing electromagnetic forces to mix five distinct metals into a single, homogeneous alloy.

The Core Takeaway Synthesizing high-entropy alloys requires precise equiatomic ratios (equal parts of each metal). The VIM furnace is essential because it prevents active elements like Manganese and Chromium from oxidizing or evaporating, while its inherent stirring mechanism ensures the complex mixture is uniform throughout the ingot.

Preserving Chemical Composition

The Challenge of Active Elements

Producing the CoCrFeMnNi alloy is chemically difficult because it contains Manganese (Mn) and Chromium (Cr).

These elements are highly "active," meaning they react readily with oxygen at high temperatures. Without protection, they would oxidize rapidly, leading to slag formation and impurities in the final product.

preventing Oxidative Loss

The VIM furnace solves this by operating under a high vacuum or a controlled inert gas atmosphere (such as argon).

By removing oxygen from the melting chamber, the furnace prevents the oxidative loss of Mn and Cr. This ensures that the final alloy retains the precise chemical balance required to be classified as a true high-entropy alloy.

Achieving Structural Homogeneity

Mixing Five Distinct Metals

Unlike traditional alloys that are mostly one base metal (like iron in steel), this high-entropy alloy requires mixing five different elements in equal amounts.

Simply melting them together often leads to segregation, where heavier elements sink or lighter elements float, resulting in an uneven composition.

The Role of Electromagnetic Stirring

The defining feature of the induction furnace is its ability to generate electromagnetic stirring.

As the induction coil heats the metal, it generates magnetic fields that churn the molten pool. This forces the five primary metals to mix thoroughly, distributing them uniformly within the melt and establishing the conditions necessary for high-quality ingot production.

Understanding the Trade-offs

Process Complexity vs. Material Quality

While VIM is excellent for homogeneity and purity, it introduces complexity regarding volatile elements.

Even under vacuum, elements with very high vapor pressures (like Manganese) can still evaporate if the pressure and temperature are not strictly controlled.

Alternative Processing Routes

It is important to note that VIM creates bulk ingots (casting).

If your goal is to avoid casting defects like coarse dendritic formations entirely, you might consider powder metallurgy routes (using vacuum hot press furnaces). However, for producing solid, bulk alloy stock, VIM remains the standard for achieving melt uniformity.

Making the Right Choice for Your Goal

When selecting a production method for CoCrFeMnNi alloys, consider your specific end-goal requirements:

- If your primary focus is compositional accuracy: Prioritize the VIM furnace for its ability to protect active elements (Mn, Cr) from oxidation via vacuum or inert gas environments.

- If your primary focus is microstructural uniformity: Rely on the VIM process, as the electromagnetic stirring prevents segregation of the five distinct elements.

Ultimately, the VIM furnace is the gatekeeper of quality, transforming a complex mix of reactive metals into a stable, uniform high-entropy alloy.

Summary Table:

| Feature | Function in CoCrFeMnNi Production | Benefit to High-Entropy Alloys |

|---|---|---|

| Vacuum/Inert Environment | Prevents oxidation of active elements (Mn, Cr) | Maintains precise equiatomic chemical ratios |

| Electromagnetic Stirring | Forces thorough mixing of 5 distinct metals | Eliminates element segregation for homogeneity |

| Induction Heating | Rapid, controlled temperature application | Minimizes thermal exposure of volatile elements |

| Atmosphere Control | Regulates chamber vapor pressure | Reduces evaporation loss of Manganese |

Elevate Your Material Synthesis with KINTEK

Precise control over chemical composition and structural homogeneity is non-negotiable for high-performance equiatomic alloys. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Vacuum Induction Melting (VIM) systems designed to handle the complex requirements of high-entropy alloy production.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temperature furnaces are fully customizable to meet your unique research and industrial needs.

Ready to achieve superior melt quality? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Tae Hyeong Kim, Jae Wung Bae. Suppressed Plastic Anisotropy via Sigma-Phase Precipitation in CoCrFeMnNi High-Entropy Alloys. DOI: 10.3390/ma17061265

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is maintaining a low-pressure vacuum environment necessary during induction heating graphitization?

- What additional features might advanced induction heater circuits incorporate? Enhance Precision, Efficiency, and Safety

- What industries commonly use induction-heated vacuum furnaces? Unlock High-Purity, High-Performance Material Processing

- What are the advantages of induction heating? Achieve Fast, Precise, and Efficient Industrial Heating

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What is the role of a vacuum arc furnace in Sn-Ag-Cu-Mn-Er solder alloy smelting? Precision Melting for Purity

- What are the main advantages of using a VIM furnace? Achieve High-Purity Metals with Precision Control

- What are the key segments of the IGBT induction melting furnace market? A Guide to Modern Metal Melting