At its core, induction heating offers three primary advantages: speed, precision, and energy efficiency. Unlike traditional furnaces that heat an object from the outside, induction heating generates heat directly within the material itself, resulting in a faster, cleaner, and far more controllable process.

The fundamental advantage of induction heating is its ability to deliver highly localized, instantaneous heat without physical contact. This transforms manufacturing by enabling faster production cycles, higher quality parts, and a safer, cleaner working environment compared to conventional flame or resistance heating methods.

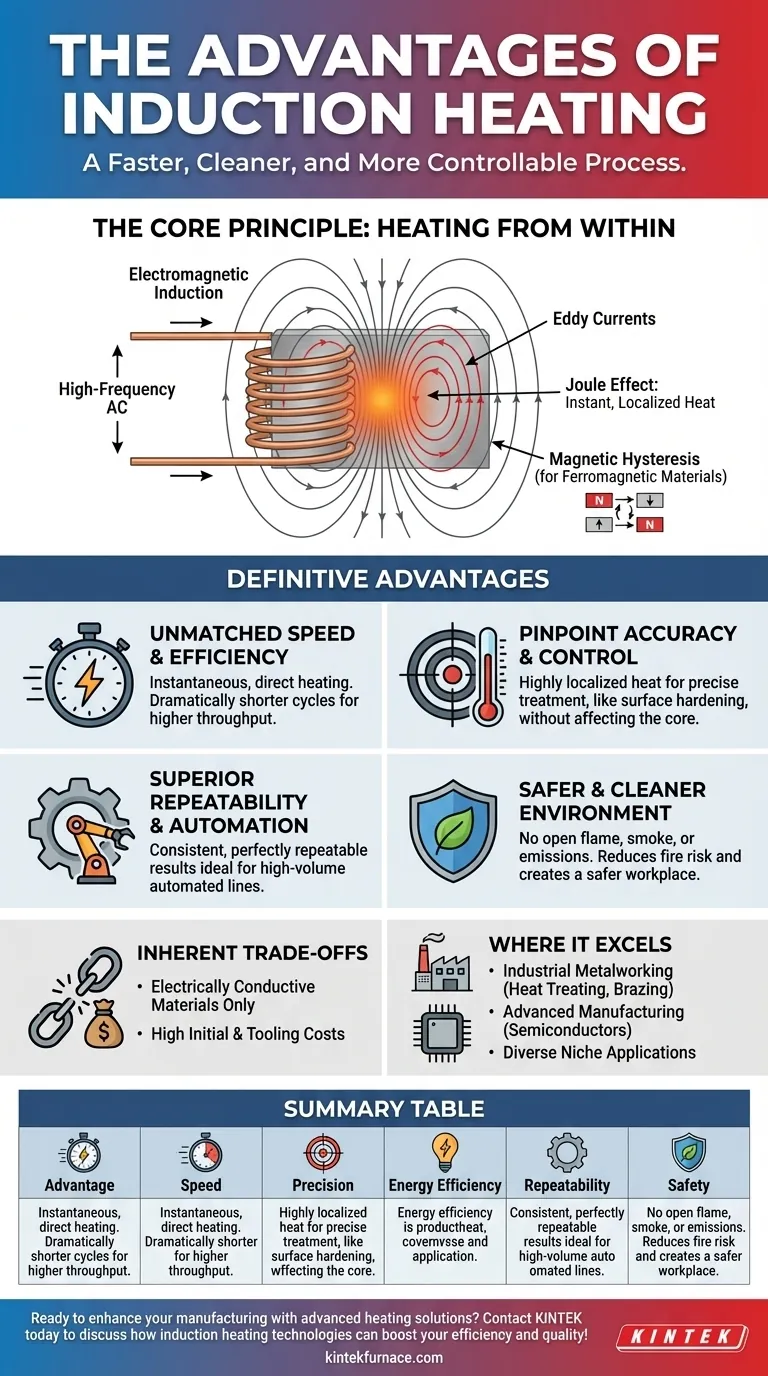

The Core Principle: Heating from Within

Induction heating is a non-contact process. It relies on fundamental laws of physics to turn electrically conductive materials into their own heat sources, offering a level of control that external heating methods cannot match.

Electromagnetic Induction

The process begins with an induction coil, through which a high-frequency alternating current (AC) is passed. This current generates a powerful and rapidly changing magnetic field around the coil.

The Joule Effect

When an electrically conductive workpiece, such as a piece of metal, is placed inside this magnetic field, the field induces circulating electrical currents within the metal. These are known as eddy currents. As these currents flow against the material's electrical resistance, they generate intense, localized heat—a phenomenon known as the Joule effect.

Magnetic Hysteresis (in Ferromagnetic Materials)

For magnetic materials like iron, there is a secondary source of heat. The rapidly alternating magnetic field causes the material's magnetic domains to quickly flip their orientation, creating internal friction and thus additional heat. This effect, known as hysteresis loss, ceases once the material passes its Curie temperature and loses its magnetic properties.

The Definitive Advantages of Induction Heating

Understanding the "heating from within" principle clarifies why this technology provides such significant operational benefits in industrial settings.

Unmatched Speed and Efficiency

Because heat is generated instantly and directly inside the part, heating cycles are dramatically shorter than with convection or radiation ovens. This translates to higher throughput. The process is also highly energy-efficient, as energy is transferred directly to the workpiece with minimal waste heat escaping into the surrounding environment.

Pinpoint Accuracy and Control

The heating effect is confined almost exclusively to the area of the part located within or near the coil. This allows for the precise surface hardening of a specific area on a part (like a gear tooth) while leaving the core material's properties unchanged. Temperature is controlled with incredible accuracy by adjusting the current, voltage, and frequency.

Superior Repeatability and Automation

Once an induction system is configured for a specific part, the process is perfectly repeatable. This makes it ideal for automated manufacturing lines, ensuring that every part receives the exact same heat treatment. This consistency is critical for high-quality production in industries like automotive and aerospace.

A Safer and Cleaner Work Environment

Induction heating produces no smoke, noxious emissions, or loud noise. With no open flame, it dramatically reduces fire risk and creates a much cooler and safer environment for operators compared to traditional forges or furnaces.

Understanding the Inherent Trade-offs

While powerful, induction heating is not a universal solution. Its effectiveness is bound by specific physical and economic constraints.

Material Limitations

The primary requirement for induction heating is that the material must be electrically conductive. It is highly effective on metals and semiconductors but cannot be used to directly heat non-conductive materials like most ceramics or plastics.

High Initial and Tooling Costs

The initial investment for induction heating equipment can be substantial. Furthermore, the inductor coil is a specialized tool that must often be custom-designed and engineered for the specific geometry of the part being heated. This tooling can be complex and expensive, especially for intricate shapes.

Where Induction Heating Excels

The unique combination of speed, precision, and control makes induction technology the preferred choice for a wide range of critical applications.

Industrial Metalworking

This is the technology's most common application. It is used extensively for heat treating, surface hardening, melting, brazing, welding, and soldering metals where quality and repeatability are paramount.

Advanced Manufacturing

In the semiconductor industry, induction heating is used for growing high-purity silicon crystals and for zone refining processes. Its clean, non-contact nature is essential for preventing contamination.

Diverse Niche Applications

The technology is also used for curing adhesives and coatings, sealing caps onto containers, and in plastic processing. Emerging applications even include using induction pyrolysis to create biochar for agricultural use.

Making the Right Choice for Your Application

Selecting the right heating method depends entirely on your project's most critical outcome.

- If your primary focus is precision and part quality: Choose induction for its unmatched ability to apply localized heat and maintain exact temperature control, perfect for surface hardening or brazing complex joints.

- If your primary focus is production speed and throughput: Choose induction for its instantaneous heating cycles, which are ideal for automated, high-volume manufacturing lines.

- If your primary focus is workplace safety and environmental impact: Choose induction to eliminate open flames, toxic emissions, and excess waste heat, creating a cleaner and safer operation.

Ultimately, embracing induction heating is a strategic decision to prioritize control, consistency, and efficiency in your thermal processing.

Summary Table:

| Advantage | Description |

|---|---|

| Speed | Instantaneous heating from within, reducing cycle times and increasing throughput. |

| Precision | Highly localized heat for accurate temperature control and surface hardening. |

| Energy Efficiency | Direct heat transfer to the workpiece minimizes energy waste. |

| Repeatability | Consistent results ideal for automated production lines. |

| Safety | No open flames, emissions, or noise for a cleaner work environment. |

Ready to enhance your manufacturing with advanced heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our induction heating technologies can boost your efficiency and quality!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies