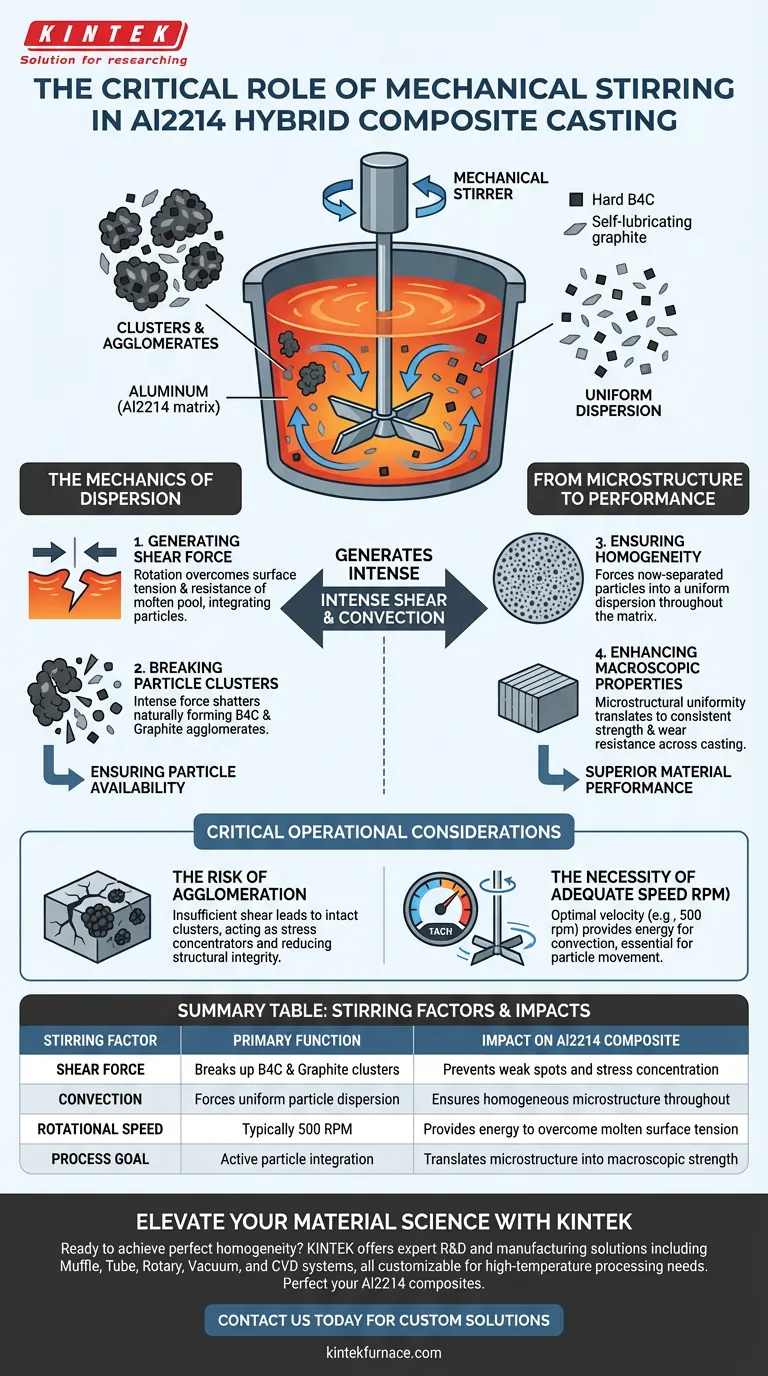

The mechanical stirrer serves as the critical active agent in the stir casting of Al2214 hybrid composites. Its primary function is to generate intense convection and shear forces—typically operating at speeds around 500 rpm—to physically break apart clusters of reinforcement particles and force them into a uniform dispersion throughout the molten aluminum matrix.

The mechanical stirrer bridges the gap between raw ingredients and a high-performance composite. By mechanically enforcing a uniform microstructure, it prevents particle clumping and ensures the final material achieves the superior mechanical properties inherent to the hybrid design.

The Mechanics of Dispersion

To understand the stirrer's importance, one must look beyond simple mixing. The goal is not just combination, but the precise distribution of distinct materials.

Generating Shear Force

The rotation of the stirrer creates powerful shear forces within the molten pool.

These forces are necessary to overcome the surface tension and physical resistance of the molten aluminum. Without this intense mechanical action, the reinforcement particles would simply float or sink rather than integrating.

Breaking Particle Clusters

In Al2214 hybrid composites, reinforcement particles like hard B4C (Boron Carbide) and self-lubricating graphite naturally tend to form clusters or agglomerates.

The stirrer’s core function is to shatter these clusters. By breaking them down, the stirrer ensures that individual particles are available for distribution rather than remaining in ineffective clumps.

From Microstructure to Performance

The activity occurring in the molten state directly dictates the quality of the solid composite.

Ensuring Homogeneity

The stirrer forces the now-separated particles into a uniform dispersion throughout the matrix.

This creates a homogeneous microstructure where the reinforcements are spaced evenly. This uniformity is the defining characteristic of a successfully cast hybrid composite.

Enhancing Macroscopic Properties

Microstructural uniformity translates directly to macroscopic mechanical properties.

A well-stirred composite exhibits consistent strength and wear resistance across the entire casting. Conversely, poor stirring leads to weak spots and unpredictable failure points.

Critical Operational Considerations

While the stirrer is essential, its effectiveness relies on precise operation. This process is not without potential pitfalls.

The Risk of Agglomeration

If the shear force is insufficient, particle clusters will remain intact.

These agglomerates act as stress concentrators in the final product, significantly reducing the material's structural integrity. The stirrer must prevent this defect to ensure the composite functions as intended.

The Necessity of Adequate Speed

The primary reference highlights specific speeds, such as 500 rpm, as effective for this process.

Running the stirrer below the optimal speed fails to generate the convection needed to move the particles. It is the velocity of the stir that dictates the energy available to disperse the B4C and graphite.

Making the Right Choice for Your Goal

To maximize the performance of Al2214 hybrid composites, you must focus on the relationship between stirring parameters and material quality.

- If your primary focus is Microstructural Uniformity: Prioritize maintaining a consistent stirring speed (e.g., 500 rpm) to generate continuous convection currents.

- If your primary focus is Mechanical Strength: Ensure the stirrer is generating sufficient shear force to completely break up B4C and graphite clusters before solidification.

Effective stir casting is defined by the stirrer's ability to transform a mixture of ingredients into a unified, high-performance material.

Summary Table:

| Stirring Factor | Primary Function | Impact on Al2214 Composite |

|---|---|---|

| Shear Force | Breaks up B4C & Graphite clusters | Prevents weak spots and stress concentration |

| Convection | Forces uniform particle dispersion | Ensures homogeneous microstructure throughout |

| Rotational Speed | Typically 500 RPM | Provides energy to overcome molten surface tension |

| Process Goal | Active particle integration | Translates microstructure into macroscopic strength |

Elevate Your Material Science with KINTEK

Ready to achieve perfect homogeneity in your metal matrix composites? Backed by expert R&D and manufacturing, KINTEK offers precision Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique high-temperature processing needs. Whether you are perfecting Al2214 hybrid composites or developing next-generation materials, our lab furnaces provide the thermal stability required for superior results. Contact us today to find your custom solution!

Visual Guide

References

- Revanna Kambaiah, Anteneh Wogasso Wodajo. Mechanical‐wear behavior and microstructure analysis of Al2214 alloy with <scp>B<sub>4</sub>C</scp> and graphite particles hybrid composites. DOI: 10.1002/eng2.12876

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the advantages of vacuum casting? Ideal for High-Fidelity Prototypes and Low-Volume Production

- What role does a medium-frequency induction furnace play in TiCp/Fe composite preparation? Expert Insights

- Why are IGBT modules preferred in melting machines? Unlock Faster Melting & Lower Costs

- Why is a high-vacuum induction melting furnace required for near alpha-titanium alloys? Ensure Purity & Performance

- How is the penetration depth of eddy currents determined in induction heating? Master Frequency, Resistivity, and Permeability

- How does electromagnetic stirring in IGBT induction melting furnaces improve melt quality? Achieve Superior Metal Purity and Homogeneity

- How does an induction furnace improve the purity of melted gold? Achieve Maximum Purity and Yield

- What is the function of a vacuum induction heating system in Al-Si and Al-Cu alloy prep? Ensuring Purity & Homogeneity