Vacuum casting is a superior method for producing small batches of high-fidelity, production-quality parts. Its primary advantages over processes like CNC machining or injection molding are its ability to replicate complex geometries with exceptional surface detail at a fraction of the cost and time of creating hard tooling. This makes it an ideal solution for functional prototypes, marketing samples, and low-volume production runs.

While many processes can create a part, the challenge is often balancing quality, speed, and cost for low-volume needs. Vacuum casting solves this by using inexpensive silicone molds to create parts that look and feel like final products, bridging the gap between one-off 3D prints and mass-produced injection molding.

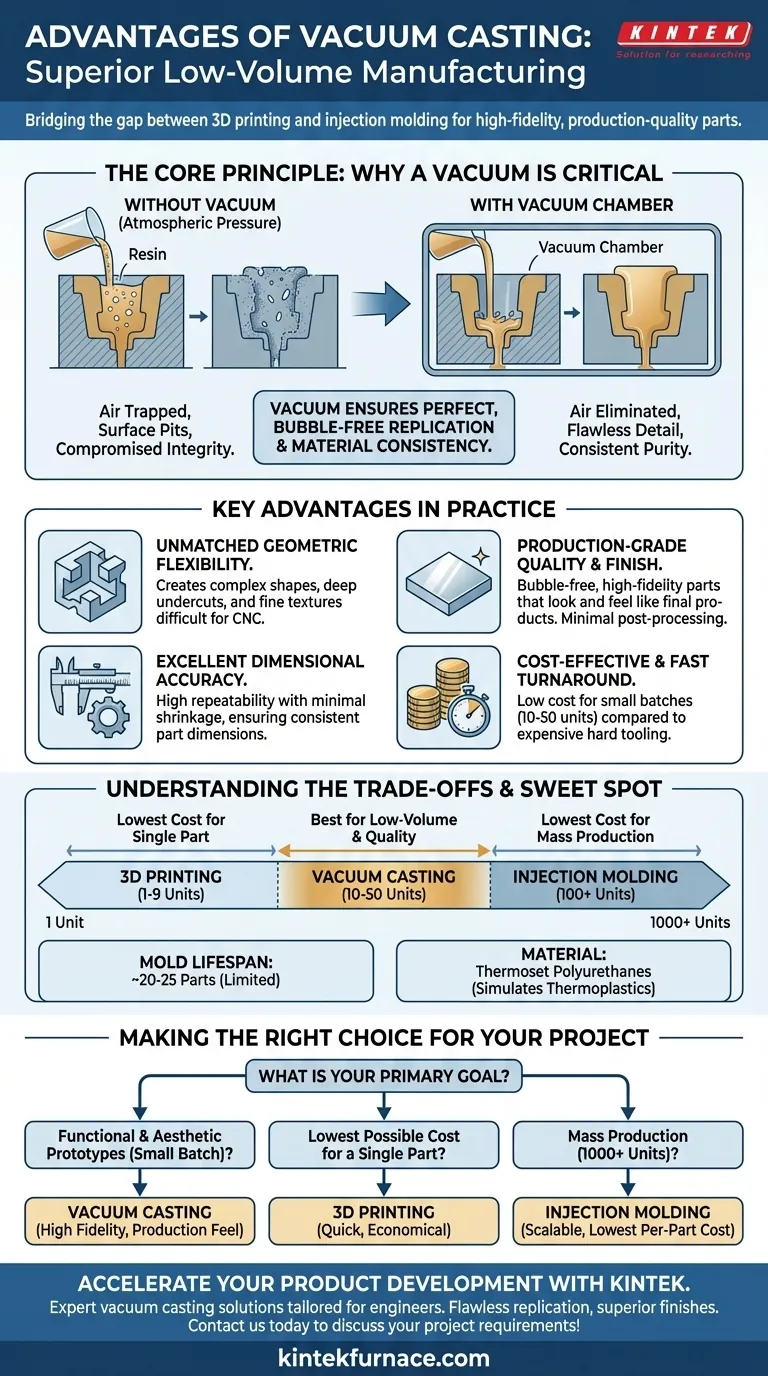

The Core Principle: Why a Vacuum Is Critical

The "vacuum" in vacuum casting is not just a name; it is the key to the process's high quality. The entire casting process takes place in a vacuum chamber, which fundamentally changes the outcome compared to pouring resin under normal atmospheric conditions.

Eliminating Air for Flawless Detail

When pouring liquid resin into a mold, tiny air bubbles can become trapped in corners, on textured surfaces, or within the material itself. These bubbles result in surface pits and internal voids, compromising both the aesthetic finish and the structural integrity of the part.

By placing the silicone mold and resin inside a vacuum chamber, all air is removed before the resin is introduced. This ensures the polyurethane resin flows into every single crevice and detail of the mold cavity, resulting in a perfect, bubble-free replication of the master pattern.

Ensuring Material Purity and Consistency

The controlled environment of a vacuum chamber also prevents contamination. It eliminates the risk of airborne dust or moisture interfering with the chemical reaction of the curing resin.

This guarantees a clean, pure cure, leading to consistent material properties and predictable performance across every part in a batch. The resulting components are strong, with uniform density and a high-quality surface finish that often requires no post-processing.

Key Advantages in Practice

The principles of a vacuum environment translate into tangible benefits for engineers and product designers.

Unmatched Geometric Flexibility

Vacuum casting is renowned for its ability to produce parts with highly complex geometries, deep undercuts, and fine surface textures. Creating these features with CNC machining would be extremely difficult and time-consuming, while the tooling for injection molding would be prohibitively expensive.

Production-Grade Quality and Finish

Parts produced via vacuum casting have an appearance and feel that is nearly indistinguishable from injection-molded products. The process supports a wide range of polyurethane resins that can mimic the properties of production plastics, from rigid and clear ABS-like materials to flexible, rubber-like elastomers.

Excellent Dimensional Accuracy

The process is highly repeatable, delivering excellent dimensional accuracy from part to part. Because the polyurethane resin cures at low pressure and temperature, there is minimal shrinkage or warping, a common issue in other thermal-based processes. This accuracy is achieved without the need for secondary finishing operations.

Understanding the Trade-offs

While powerful, vacuum casting is not the right choice for every situation. Understanding its limitations is key to using it effectively.

The Cost-per-Part Equation

Vacuum casting is most cost-effective for low-volume runs, typically between 10 and 50 units. For a single, one-off part, 3D printing is often cheaper. For high-volume production (hundreds or thousands of units), the per-part cost of injection molding becomes far lower, justifying the high initial tooling investment.

Silicone Mold Lifespan

The soft silicone molds used in vacuum casting are inexpensive to create but have a limited lifespan. They begin to degrade from thermal and chemical exposure after producing around 20 to 25 parts. This is the primary factor that makes vacuum casting unsuitable for mass production.

Material Limitations

While the range of polyurethane resins is broad, they are ultimately thermoset materials that simulate thermoplastics. If your application strictly requires the exact mechanical or thermal properties of a specific production-grade thermoplastic (like polycarbonate or nylon), you may need to use a different process.

Making the Right Choice for Your Project

Selecting the correct manufacturing process depends entirely on your specific goals for quality, quantity, and cost.

- If your primary focus is functional and aesthetic prototypes: Vacuum casting is likely your best choice for creating a small batch of parts that look and feel like the final product.

- If your primary focus is the lowest possible cost for a single part: A 3D print (like FDM or SLA) is often more economical for a one-off design validation model.

- If your primary focus is mass production (1000+ units): You must invest in hard tooling for a process like injection molding to achieve the lowest cost-per-part at scale.

By understanding where vacuum casting fits in the manufacturing landscape, you can confidently select the right process to bring your design to life.

Summary Table:

| Advantage | Description |

|---|---|

| Geometric Flexibility | Excels at complex shapes, deep undercuts, and fine textures, hard to achieve with CNC machining. |

| Surface Quality | Produces bubble-free, high-fidelity parts with excellent finish, often no post-processing needed. |

| Cost-Effectiveness | Low cost for small batches (10-50 units) vs. expensive hard tooling in injection molding. |

| Speed | Faster turnaround for prototypes and low-volume runs compared to traditional methods. |

| Material Versatility | Uses polyurethane resins to mimic various plastics, from rigid to flexible properties. |

| Dimensional Accuracy | High repeatability with minimal shrinkage, ensuring consistent part dimensions. |

Need high-quality prototypes or low-volume parts? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced vacuum casting solutions tailored for engineers and product developers. Our expertise ensures flawless replication of complex geometries with superior surface finishes, helping you accelerate product development. Contact us today to discuss how our customized services can meet your unique project requirements and deliver production-grade results efficiently!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength