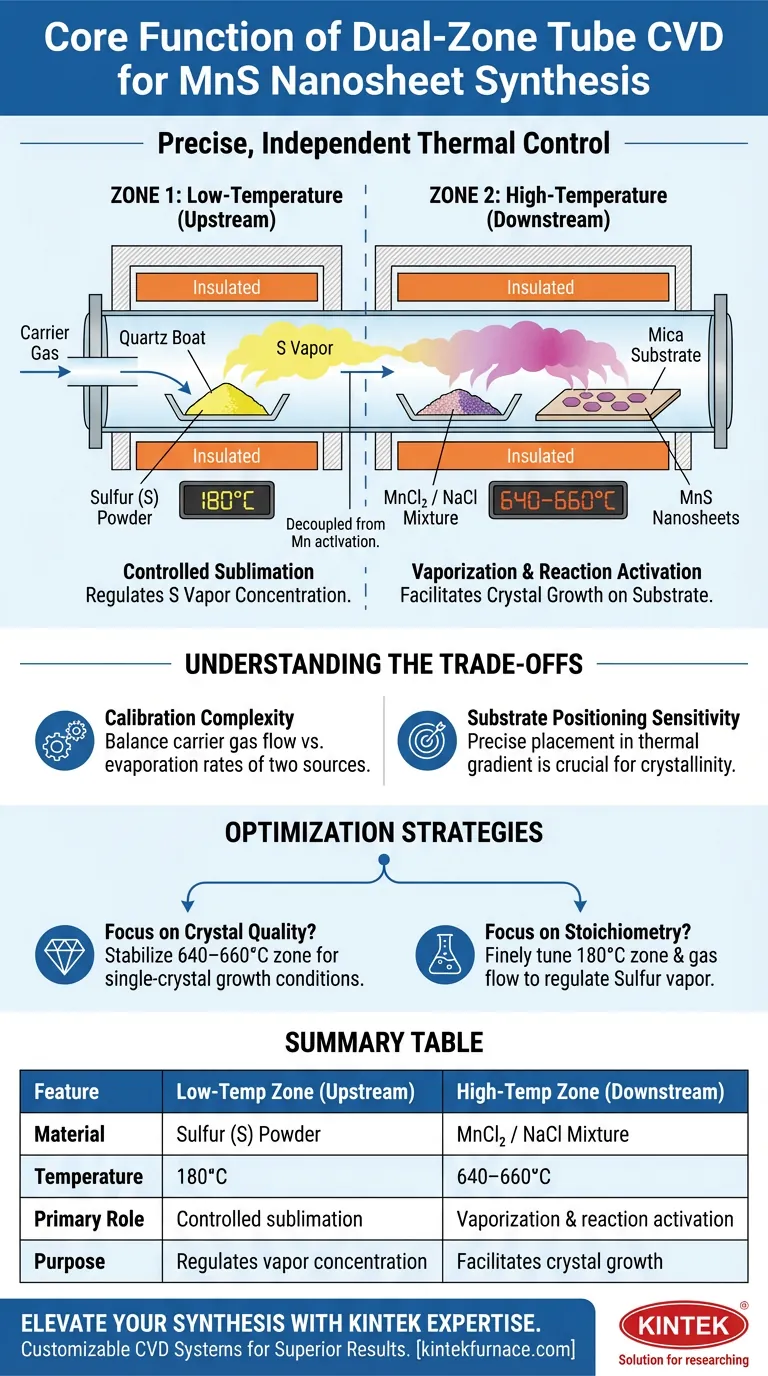

The core function of a dual-zone tube CVD system is to provide precise, independent thermal control over distinct precursor materials. In the synthesis of Manganese Sulfide (MnS) nanosheets, this configuration is essential because it allows Sulfur (S) powder to sublime at a low temperature (180°C) while simultaneously maintaining a Manganese Chloride (MnCl2) mixture at a much higher reaction temperature (640–660°C). This separation enables the precise regulation of chemical vapor concentrations required to grow high-quality nanocrystals on mica substrates.

By decoupling the sublimation of sulfur from the activation of the manganese precursor, the dual-zone system creates the specific thermodynamic environment necessary for the controlled growth of non-layered MnS structures.

The Mechanics of Independent Temperature Control

The Low-Temperature Zone (Upstream)

The primary role of the first zone is the controlled sublimation of the chalcogen source.

For MnS synthesis, Sulfur (S) powder is placed in this low-temperature region, specifically set to 180°C. This temperature is sufficient to generate sulfur vapor without inducing premature reactions or rapid depletion of the material.

The High-Temperature Zone (Downstream)

The second zone creates the high-energy environment required for the metal precursor to react.

Here, a mixture of MnCl2 and NaCl is heated to 640–660°C. This high thermal energy is necessary to vaporize the manganese salt and facilitate its reaction with the incoming sulfur vapor on the substrate.

Regulating Vapor Concentration

The separation of zones allows for the independent tuning of vapor pressure for each reactant.

If both precursors were heated in a single zone, the sulfur would evaporate excessively fast before the manganese chloride reached its vaporization point. The dual-zone setup ensures that the correct ratio of Mn and S vapors meet at the substrate surface.

Understanding the Trade-offs

Calibration Complexity

While a dual-zone system offers superior control, it introduces significant operational variables.

Operators must carefully balance the carrier gas flow rate against the evaporation rates of two different sources. A misalignment in the temperature gradient between zones can lead to unstable vapor transport or inconsistent film thickness.

Substrate Positioning Sensitivity

The success of the deposition relies heavily on the precise placement of the substrate within the thermal gradient.

Because the reaction kinetics change rapidly across the temperature fall-off downstream, even minor deviations in substrate position can result in poor crystallinity or unwanted morphologies.

Making the Right Choice for Your Goal

To maximize the effectiveness of a dual-zone CVD system for MnS synthesis, consider your specific objectives:

- If your primary focus is crystal quality: Prioritize the precise stabilization of the 640–660°C zone to ensure the thermodynamic conditions favor single-crystal growth on the mica substrate.

- If your primary focus is stoichiometry control: Finely tune the low-temperature zone (180°C) and carrier gas flow to strictly regulate the amount of Sulfur vapor reaching the reaction zone.

Mastering the thermal gradient between these two zones is the defining factor in transitioning from random deposition to controlled nanosheet synthesis.

Summary Table:

| Feature | Low-Temperature Zone (Upstream) | High-Temperature Zone (Downstream) |

|---|---|---|

| Material | Sulfur (S) Powder | MnCl2 / NaCl Mixture |

| Temperature | 180°C | 640–660°C |

| Primary Role | Controlled sublimation of chalcogen | Vaporization and reaction activation |

| Purpose | Regulates sulfur vapor concentration | Facilitates crystal growth on substrate |

Elevate Your Material Synthesis with KINTEK Expertise

Unlock the full potential of your research with our high-precision CVD systems. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique thermodynamic requirements of your lab. Whether you are synthesizing MnS nanosheets or exploring new 2D materials, our dual-zone configurations provide the precise independent thermal control you need to achieve superior crystal quality.

Ready to optimize your high-temperature processes? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Chaojie Xie, Yu Zhao. A Broadband Photodetector Based on Non-Layered MnS/WSe2 Type-I Heterojunctions with Ultrahigh Photoresponsivity and Fast Photoresponse. DOI: 10.3390/ma17071590

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is Chemical Vapor Deposition (CVD)? Unlock High-Purity Thin Film Solutions

- What are some common applications of Chemical Vapor Deposition? Unlock High-Performance Thin Films for Your Industry

- Why is high-precision gas flow control essential for the CVD of graphene-palladium? Master Material Quality Control

- What are the benefits of CVD coatings in aerospace and automotive industries? Boost Durability and Efficiency

- What materials are used in CVD? A Guide to High-Performance Thin Films for Your Lab

- What role does a Vertical Cold Wall MOCVD system play in WSe2 synthesis? Expert Insights on Epitaxial Growth

- What are the key components of a CVD Tube Furnace? Essential Systems for Precise Thin-Film Deposition

- What is the high-temperature capability of specialized CVD furnaces? Achieve Up to 1950°C for Advanced Materials