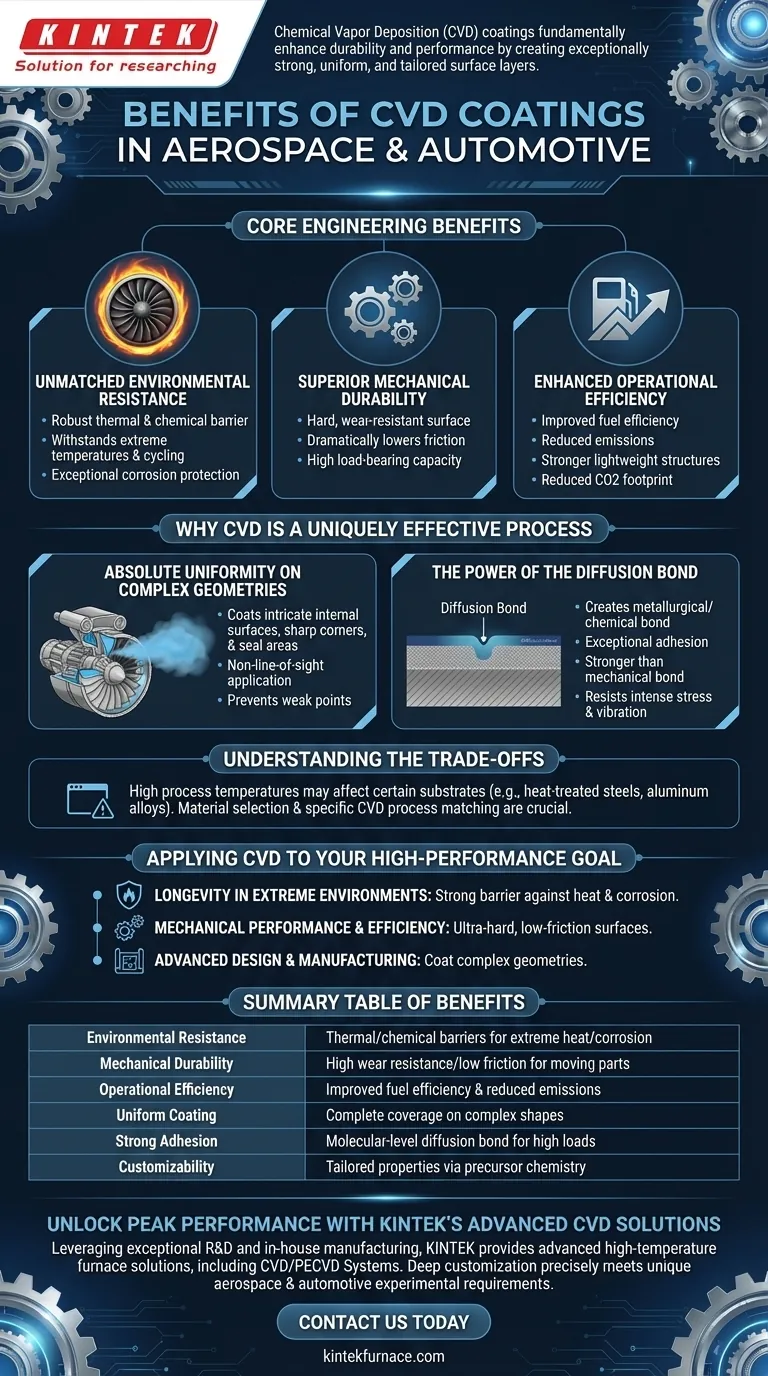

In short, Chemical Vapor Deposition (CVD) coatings are used in the aerospace and automotive industries to fundamentally enhance the durability and performance of critical components. By creating an exceptionally strong, uniform, and precisely tailored surface layer, CVD provides unparalleled protection against high temperatures, wear, and corrosion, directly improving efficiency and operational lifespan.

The true value of CVD lies not just in the protective properties it imparts, but in the unique nature of its application process. Its ability to create a perfectly uniform coating on even the most complex geometries and form a molecular-level bond with the substrate is what sets it apart for high-stress applications.

The Core Engineering Benefits of CVD

CVD coatings solve critical engineering challenges in environments where failure is not an option. The benefits are directly tied to improving the physical and chemical resilience of a component's surface.

Unmatched Environmental Resistance

Components in engines and exhaust systems are exposed to extreme heat and corrosive agents. CVD provides a robust thermal and chemical barrier.

The process creates a highly durable coating-to-substrate bond that can withstand extreme temperatures and rapid thermal cycling without delaminating.

This barrier also delivers exceptional corrosion resistance, protecting the underlying material from chemical attack and extending the component's service life.

Superior Mechanical Durability

Moving parts are subject to constant friction and mechanical stress. CVD coatings significantly reduce these failure modes.

They provide a hard, wear-resistant surface that dramatically lowers the coefficient of friction. This is critical for parts like fuel injection systems and other engine components where wear resistance is paramount.

The exceptional adhesion, resulting from a diffusion bond at the molecular level, gives the coating a high load-bearing capacity, ensuring it remains intact even under high-stress conditions.

Enhanced Operational Efficiency

By improving the physical properties of components, CVD coatings contribute directly to system-level performance gains.

Reduced friction and better wear resistance in engine parts lead to improved fuel efficiency and, consequently, reduced emissions.

In aerospace, the technology also enhances the adhesion of composite materials, contributing to stronger and more reliable lightweight structures. The process can also have a reduced CO2 footprint compared to some alternative coating technologies.

Why CVD is a Uniquely Effective Process

The benefits of a CVD coating are a direct result of the process itself. Unlike line-of-sight methods (like spraying), CVD is a chemical process that builds the coating atom by atom on every exposed surface.

Absolute Uniformity on Complex Geometries

A key advantage of CVD is its ability to deposit a perfectly uniform coating regardless of the part's shape.

The process uses a precursor gas that surrounds the component, ensuring that even intricate internal surfaces, sharp corners, and seal areas are coated completely and evenly. This non-line-of-sight application prevents weak points where the base substrate might be exposed.

The Power of the Diffusion Bond

CVD doesn't just lay a coating on top of the material; it creates a metallurgical or chemical bond with it.

This diffusion bond means the coating is integrated into the substrate's surface, resulting in exceptional adhesion that is far stronger than a simple mechanical bond. This is why CVD-coated parts perform so well under intense mechanical stress and vibration.

Tailored Properties Through Precursor Chemistry

The CVD process is highly versatile, allowing for precise control over the final properties of the coating.

By changing the composition of the precursor gas, engineers can optimize the coating for specific requirements, such as enhanced lubricity, chemical inertness, high purity, or extreme hardness.

Versatility Across Substrates

CVD is not limited to a single type of material. It is compatible with a wide range of substrates.

The process can be successfully applied to metals, metal alloys, ceramics, and even glass, making it a flexible solution for a diverse set of engineering challenges in both the automotive and aerospace sectors.

Understanding the Trade-offs

While immensely powerful, CVD is not a universal solution. Like any engineering process, it involves specific considerations. The most significant is temperature.

Many CVD processes operate at high temperatures to facilitate the necessary chemical reactions. This can be a limitation for certain substrates, such as heat-treated steels or aluminum alloys, as the process temperature could alter their fundamental mechanical properties (e.g., temper or hardness).

Therefore, material selection and the specific variant of the CVD process (e.g., lower-temperature PECVD) must be carefully matched to avoid compromising the integrity of the underlying component.

Applying CVD to Your High-Performance Goal

Your choice to use CVD should be driven by the primary problem you need to solve.

- If your primary focus is component longevity in extreme environments: The key benefit is CVD's ability to form a strongly bonded, uniform barrier against high heat and corrosion.

- If your primary focus is mechanical performance and efficiency: The primary value comes from CVD's capacity to create ultra-hard, low-friction surfaces that resist wear on complex moving parts.

- If your primary focus is advanced design and manufacturing: CVD's non-line-of-sight uniformity allows you to coat complex internal geometries that are impossible to protect with other methods.

Ultimately, CVD empowers you to engineer surfaces for performance characteristics that the bulk material alone cannot provide.

Summary Table:

| Benefit | Description |

|---|---|

| Environmental Resistance | Provides strong thermal and chemical barriers for extreme heat and corrosion protection. |

| Mechanical Durability | Offers high wear resistance and low friction for moving parts, reducing failure. |

| Operational Efficiency | Improves fuel efficiency and reduces emissions through better surface properties. |

| Uniform Coating | Ensures complete, even coverage on complex geometries via non-line-of-sight application. |

| Strong Adhesion | Creates a diffusion bond at the molecular level for exceptional load-bearing capacity. |

| Customizability | Allows tailored properties via precursor chemistry for specific application needs. |

Unlock Peak Performance with KINTEK's Advanced CVD Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for aerospace and automotive applications.

Contact us today to discuss how our tailored CVD coatings can enhance your component durability, efficiency, and reliability—let's engineer your success together!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition