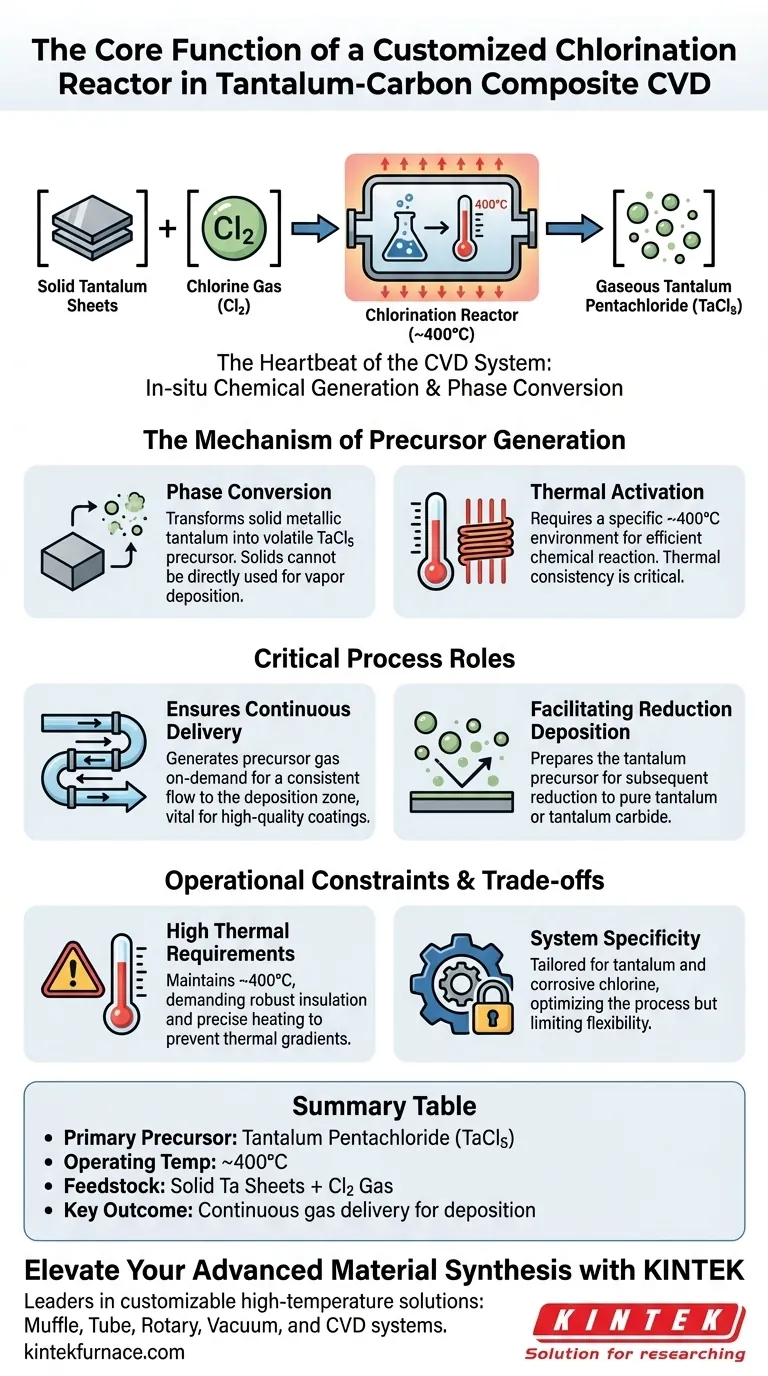

The core function of a customized chlorination reactor is to act as an in-situ chemical generator that converts solid metallic tantalum into a usable gaseous precursor. By reacting tantalum sheets with chlorine gas in a controlled environment at approximately 400°C, the system synthesizes tantalum pentachloride (TaCl5), the essential volatile compound required to initiate the Chemical Vapor Deposition (CVD) process.

The chlorination reactor bridges the gap between raw material storage and deposition by chemically transforming stable, solid metal into a reactive gas stream. This conversion is the prerequisite for achieving a continuous, controlled flow of material for the creation of tantalum-carbon composites.

The Mechanism of Precursor Generation

Phase Conversion

The primary technical challenge in this CVD process is that the source material, metallic tantalum, exists as a solid sheet. Solids cannot be directly used for vapor deposition.

The chlorination reactor solves this by facilitating a chemical reaction that alters the physical state of the material. It facilitates the interaction between the solid tantalum and chlorine gas to produce tantalum pentachloride (TaCl5).

Thermal Activation

This chemical conversion is not spontaneous at room temperature; it requires significant thermal energy to proceed efficiently.

The reactor is engineered to maintain a specific, high-temperature environment, typically around 400°C. This thermal consistency is critical to ensure the reaction proceeds at a rate that matches the demand of the deposition process.

Critical Process Roles

Ensuring Continuous Delivery

Consistency is vital for high-quality CVD coatings. Fluctuations in precursor supply can lead to defects or uneven thickness in the final composite.

The customized reactor allows for continuous gas delivery. By generating the precursor gas on-demand from a solid stock, the system maintains a steady flow of reactants to the deposition zone.

Facilitating Reduction Deposition

The generation of TaCl5 is only the first step; it is an intermediate compound designed to be reduced later.

By creating this specific chloride precursor, the reactor prepares the tantalum for the subsequent reduction deposition process. The TaCl5 gas is chemically ready to be stripped of its chlorine atoms and deposited as pure tantalum or tantalum carbide downstream.

Operational Constraints and Trade-offs

High Thermal Requirements

While essential for the reaction, maintaining a 400°C environment introduces energy overhead and material stress.

The system requires robust insulation and precise heating elements to prevent thermal gradients. A drop in temperature could stall the generation of TaCl5, while excessive heat could damage reactor components.

System Specificity

The reactor is described as "customized," indicating it is tailored specifically for the geometry of tantalum sheets and the corrosive nature of chlorine gas.

This customization optimizes the process but limits flexibility. The equipment is purpose-built for this specific chemical pathway and may not be easily adaptable to other precursors or metals without significant modification.

Making the Right Choice for Your Process

Understanding the role of the chlorination reactor allows you to optimize your CVD system for efficiency and quality.

- If your primary focus is Process Stability: Prioritize the thermal control of the reactor to ensure the 400°C setpoint never fluctuates, guaranteeing a steady stream of TaCl5.

- If your primary focus is Precursor Yield: Ensure the reactor design maximizes the surface area contact between the chlorine gas and the metallic tantalum sheets.

A well-tuned chlorination reactor is the heartbeat of the CVD system, turning static metal into the dynamic flow required for advanced composite manufacturing.

Summary Table:

| Feature | Function in Chlorination Reactor |

|---|---|

| Primary Precursor | Tantalum Pentachloride (TaCl5) |

| Operating Temp | Approximately 400°C |

| Feedstock Material | Solid Tantalum Sheets + Chlorine Gas |

| Key Outcome | Continuous gas delivery for vapor deposition |

| Process Role | In-situ chemical generation & phase conversion |

Elevate Your Advanced Material Synthesis with KINTEK

Precise precursor generation is the backbone of high-quality CVD coatings. As a leader in laboratory high-temperature solutions, KINTEK provides the expert R&D and manufacturing excellence your facility requires. We offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet the specific thermal and chemical demands of your unique research.

Whether you are developing tantalum-carbon composites or exploring new chemical pathways, our engineers are ready to help you optimize your process stability and yield.

Ready to design your custom CVD solution? Contact us today to speak with a specialist!

Visual Guide

References

- Junyu Zhu, Haohong Jiang. Fabrication and mechanical properties of porous tantalum carbon composites by chemical vapor deposition. DOI: 10.1038/s41598-025-86680-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why is a high vacuum magnetron sputtering system required for NiO layers? Ensure Chemical Purity and Conductivity

- What is the role of a Metal-Organic Chemical Vapor Deposition (MOCVD) system? Grow High-Quality Monolayer WS2

- What types of surface coatings can be applied using CVD furnaces? Discover Versatile Solutions for Your Needs

- Why must high vacuum and slow deposition rates be maintained for gold deposition? Unlock Precision Plasmonics

- What role do CVD furnaces play in optics? Enhance Optical Performance with Precision Coatings

- What role does a Chemical Vapor Deposition (CVD) system play in CsPbBr3 film growth? Master Single-Crystal Precision.

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision