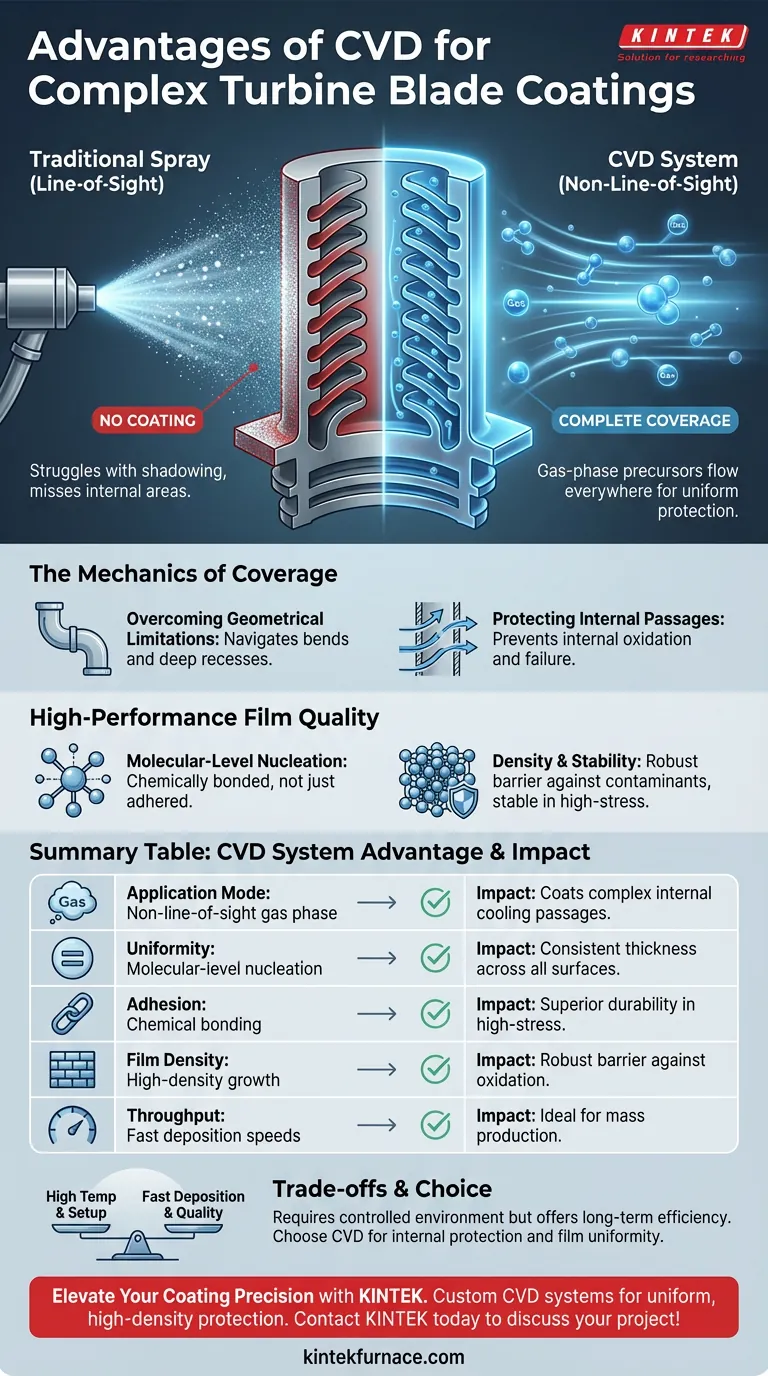

The distinctive advantage of using a Chemical Vapor Deposition (CVD) system for turbine blades is its non-line-of-sight application capability. Because the process utilizes gas-phase precursors, the coating material behaves like a gas rather than a directional spray, allowing it to flow into and coat every accessible surface. This ensures that even the most intricate internal cooling passages of a blade receive the same uniform protection as the external airfoil.

Unlike physical spray methods that require a direct path to the surface, CVD uses gas circulation to distribute elements evenly. This capability is critical for turbine components where internal integrity is just as vital as external shielding.

The Mechanics of Non-Line-of-Sight Coverage

Overcoming Geometrical Limitations

Traditional coating methods often struggle with "shadowing," where complex shapes block the coating material from reaching certain areas.

CVD eliminates this issue completely. Because the coating agents are gaseous, they can navigate around bends and through deep recesses that a line-of-sight process would miss.

Protecting Internal Cooling Passages

Modern turbine blades are engineered with sophisticated internal channels to manage extreme heat.

The primary reference highlights that CVD allows aluminum elements to be distributed evenly throughout these internal passages. This internal coverage is essential for preventing oxidation and failure from the inside out.

Gas-Phase Precursor Distribution

The system operates by introducing chemical precursors in a vapor state.

These gases circulate freely around the component, ensuring that the concentration of the coating material is consistent across the entire part. This results in superior coating uniformity regardless of the blade's complexity.

Achieving High-Performance Film Quality

Molecular-Level Nucleation

Beyond geometry, the fundamental way the coating forms contributes to its quality.

As noted in the supplementary data, CVD facilitates nucleation and growth at the molecular level. This results in a film that is chemically bonded to the substrate rather than just mechanically adhered.

Density and Stability

The nature of this growth process produces films that are exceptionally dense.

A denser film provides a more robust barrier against environmental contaminants. Furthermore, the resulting coating exhibits stable quality, which is crucial for the high-stress environment of a turbine engine.

Understanding the Trade-offs

Thermal Requirements

It is important to note that CVD is a high-temperature process.

The primary reference indicates that these reactions occur at elevated temperatures to facilitate the diffusion of aluminum. While this is beneficial for bond strength, the substrate material must be capable of withstanding this thermal cycle without degrading.

System Complexity vs. Throughput

While CVD is highly effective for complex shapes, it requires a controlled vacuum or reaction chamber environment.

However, once the parameters are set, the process features fast deposition speeds and is well-suited for mass production. The trade-off is the initial setup complexity versus the long-term efficiency and quality consistency.

Making the Right Choice for Your Goal

When evaluating coating technologies for turbine components, consider your specific engineering requirements:

- If your primary focus is internal protection: Choose CVD, as it is the only method capable of uniformly coating internal cooling passages without line-of-sight access.

- If your primary focus is film uniformity: Rely on CVD for its molecular-level growth, which ensures dense and even coverage across irregular surfaces.

By leveraging the gas-phase nature of CVD, you ensure that component complexity never compromises component longevity.

Summary Table:

| Feature | CVD System Advantage | Impact on Turbine Blades |

|---|---|---|

| Application Mode | Non-line-of-sight gas phase | Coats complex internal cooling passages |

| Uniformity | Molecular-level nucleation | Consistent thickness across external and internal surfaces |

| Adhesion | Chemical bonding | Superior durability in high-stress environments |

| Film Density | High-density growth | Robust barrier against oxidation and contaminants |

| Throughput | Fast deposition speeds | Ideal for high-volume, high-quality mass production |

Elevate Your Coating Precision with KINTEK

Don't let complex geometries compromise your component's lifespan. KINTEK provides industry-leading CVD systems designed to ensure uniform, high-density protection for your most intricate designs. Backed by expert R&D and world-class manufacturing, we offer a full range of customizable solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab or industrial high-temperature requirements.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your project!

Visual Guide

References

- Effect of Ni-Based Superalloy on the Composition and Lifetime of Aluminide Coatings. DOI: 10.3390/ma18133138

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

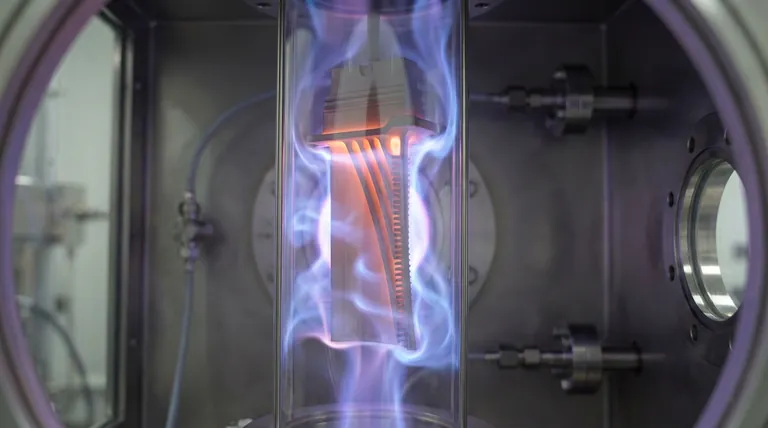

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What role does a Chemical Vapor Deposition (CVD) system play in the synthesis of NCNTs? Precision Material Engineering

- What is the process of low pressure chemical vapor deposition? Achieve Superior Thin Film Uniformity and Purity

- What is the result of the deposition process in CVD? Achieve High-Purity Thin Films for Your Applications

- How does the environment inside a CVD furnace contribute to material synthesis? Achieve Atomic Precision in Material Engineering

- What is the necessity of high-bias gas ion cleaning? Achieve Atomic-Level Coating Adhesion

- What role does a thermal evaporation coating system play in GeCC synthesis? Precision Seeding for Nanowire Growth

- What are the general reactions for metal and ceramic deposition in CVD? Master Key Processes for Superior Thin Films

- What are the steps of chemical vapor deposition? Master the Process for Superior Thin Films