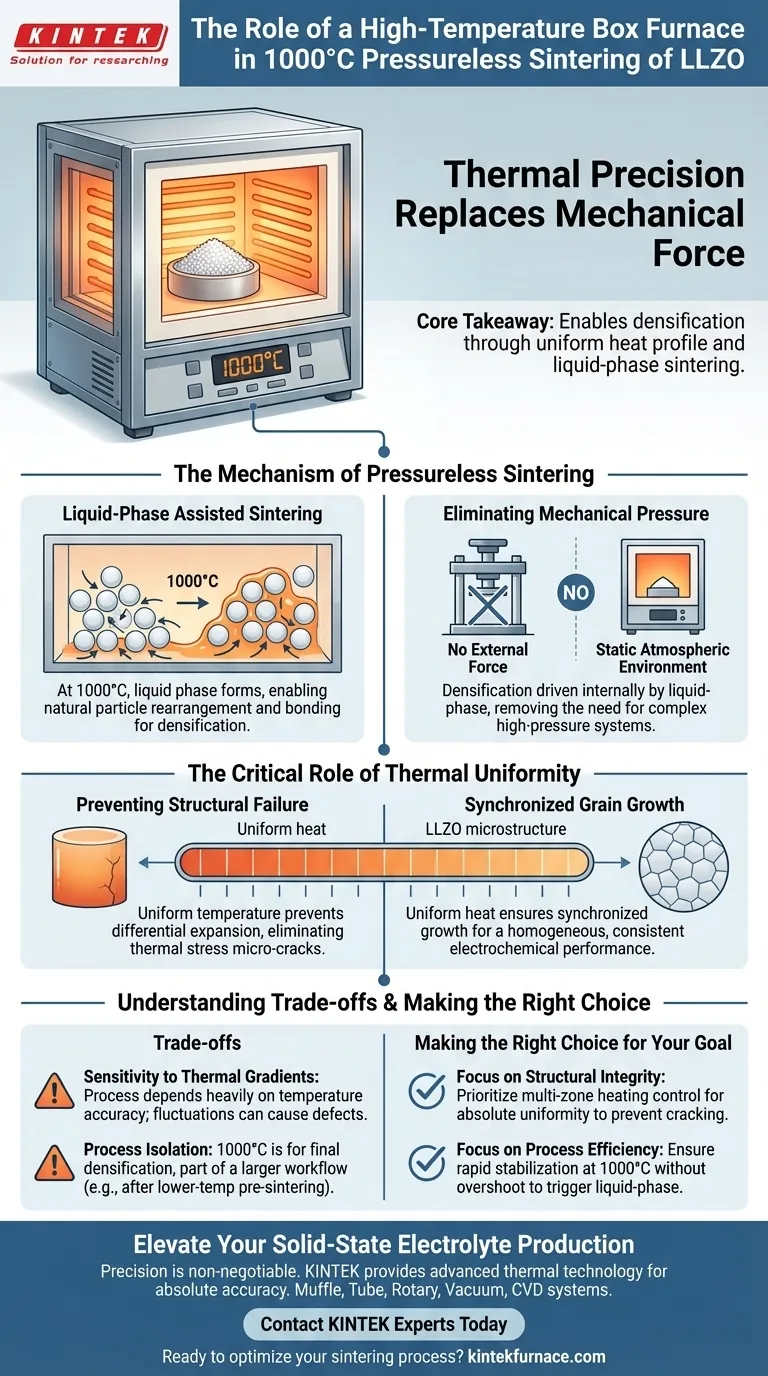

A high-temperature box furnace acts as a precise thermal chamber effectively enabling the densification of Lithium Lanthanum Zirconium Oxide (LLZO) without the need for external mechanical pressure. By maintaining a stable environment at 1000°C, the furnace facilitates liquid-phase assisted sintering, allowing the solid electrolyte to achieve the necessary density and structural integrity through thermal dynamics alone.

Core Takeaway: The furnace's primary function is to replace mechanical force with thermal precision. It creates a uniform heat profile that triggers liquid-phase sintering, ensuring the material densifies evenly while preventing the thermal stress cracks that compromise electrolyte performance.

The Mechanism of Pressureless Sintering

To understand the role of the box furnace, one must look beyond simple heating. It provides the specific conditions required for the material to bond chemically and physically on its own.

Liquid-Phase Assisted Sintering

At the specific setpoint of 1000°C, the LLZO material enters a critical phase. The box furnace maintains this temperature to induce liquid-phase assisted sintering.

In this state, a portion of the material forms a liquid phase which facilitates the rearrangement and bonding of solid particles. This process allows the material to densify naturally, closing pores and increasing the solid volume without the "squeezing" force used in hot-pressing methods.

Eliminating Mechanical Pressure

The distinction of this process is that it is pressureless.

The box furnace provides a static, atmospheric environment. Because the liquid-phase mechanism drives the densification internally, the complex hydraulic systems required for high-pressure hot re-pressing are rendered unnecessary for this specific stage of synthesis.

The Critical Role of Thermal Uniformity

The success of sintering LLZO relies heavily on how evenly heat is applied. The high-temperature box furnace is engineered to minimize thermal gradients across the chamber.

Preventing Structural Failure

LLZO is a ceramic material susceptible to thermal shock. If one part of the sample heats or cools faster than another, differential expansion occurs.

The box furnace ensures temperature uniformity, which is the primary defense against thermal stress. By keeping the thermal environment consistent, the furnace prevents the formation of micro-cracks that would otherwise destroy the electrolyte or severely hamper its ionic conductivity.

Synchronized Grain Growth

For an electrolyte to function correctly, its microscopic grain structure must be consistent.

The uniform heat provided by the furnace ensures that grain growth is synchronized across the entire sample. This results in a homogeneous microstructure, which is essential for consistent electrochemical performance throughout the material.

Understanding the Trade-offs

While the high-temperature box furnace is effective for pressureless sintering, relying solely on thermal parameters introduces specific challenges.

Sensitivity to Thermal Gradients

Because there is no external pressure to force particles together, the process is entirely dependent on temperature accuracy. Any fluctuation or "cold spot" in the furnace chamber can lead to incomplete sintering or localized defects.

Process Isolation

It is important to note that this 1000°C step is often part of a larger workflow. As noted in broader material processing contexts, this stage may follow a lower-temperature pre-sintering step (e.g., at 800°C) used to establish preliminary bonding. The box furnace at 1000°C is specifically targeting final densification, not initial forming.

Making the Right Choice for Your Goal

When configuring your sintering process for LLZO, your equipment settings should align with your specific material requirements.

- If your primary focus is Structural Integrity: Prioritize a furnace with verified multi-zone heating control to guarantee absolute temperature uniformity and prevent cracking.

- If your primary focus is Process Efficiency: Ensure your furnace can reach and stabilize at 1000°C rapidly without overshooting, as this specific temperature triggers the essential liquid-phase mechanism.

The high-temperature box furnace is the enabler of internal chemical bonding, substituting mechanical force with precise thermal control to create a dense, conductive solid electrolyte.

Summary Table:

| Feature | Function in LLZO Sintering (1000°C) |

|---|---|

| Mechanism | Facilitates liquid-phase assisted sintering without mechanical pressure |

| Thermal Profile | Ensures uniformity to prevent thermal stress cracks and micro-defects |

| Grain Control | Synchronizes grain growth for a homogeneous microstructure |

| Atmospheric State | Provides a static environment for natural densification and bonding |

Elevate Your Solid-State Electrolyte Production

Precision is non-negotiable when sintering LLZO at 1000°C. KINTEK provides the advanced thermal technology required to replace mechanical force with absolute thermal accuracy.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temperature furnaces designed for your unique material needs. Ensure synchronized grain growth and eliminate structural failure in your ceramics today.

Ready to optimize your sintering process? Contact our experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Seung Hoon Chun, Sangbaek Park. Synergistic Engineering of Template‐Guided Densification and Dopant‐Induced Pore Filling for Pressureless Sintering of Li<sub>7</sub>La<sub>3</sub>Zr<sub>2</sub>O<sub>12</sub> Solid Electrolyte at 1000 °C. DOI: 10.1002/sstr.202500297

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What temperature information is displayed simultaneously on the controls? Monitor Real-Time and Target Temperatures for Precision

- What is a muffle furnace and what are its primary uses? Unlock Precise High-Temp Solutions

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What are the primary technical improvements of a wood carbonization Kiln-Furnace System? Efficiency & Eco-Solutions

- How do crucible furnaces minimize oxidation losses? Preserve Metal Quality & Maximize Yield

- Why is a programmable temperature control box furnace required for Bi-2223? Ensure High-Purity Superconductor Synthesis

- How does a muffle furnace with a weighing system benefit biochar research? Gain Real-Time Pyrolysis Insights

- What is the main advantage of a muffle furnace? Ensure Purity and Longevity in High-Temp Processes