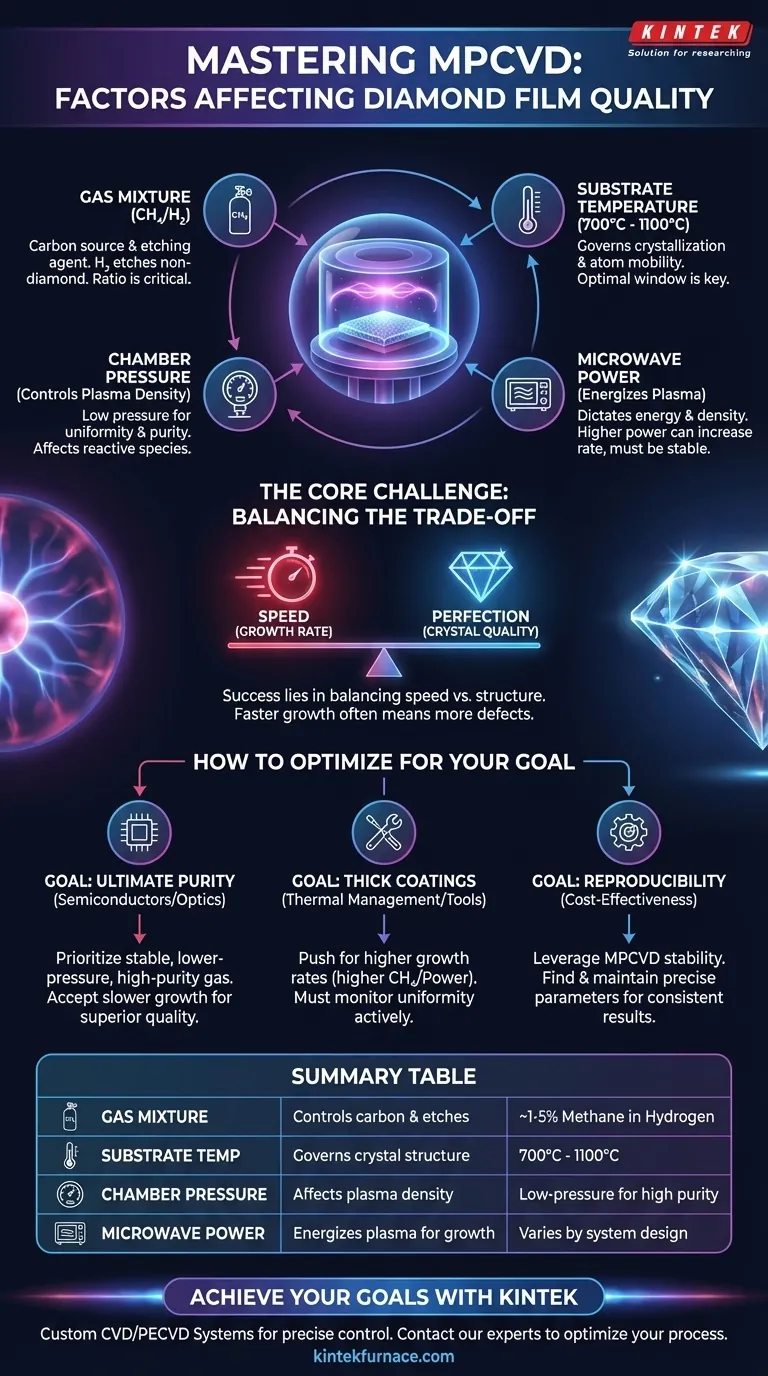

In short, the quality of a diamond film produced by Microwave Plasma Chemical Vapor Deposition (MPCVD) is determined by four primary factors: the gas mixture, the chamber pressure, the substrate temperature, and the microwave power level. The precise and stable control of these interdependent parameters is the foundation for growing high-quality, uniform diamond films suitable for advanced applications.

The core challenge in producing high-quality diamond film is not just knowing the controlling factors, but mastering their interplay. Success lies in balancing the fundamental trade-off between the speed of diamond growth and the perfection of its crystal structure.

The Core Parameters of MPCVD Diamond Growth

To achieve a desired outcome, you must understand how each process variable influences the final film. These parameters do not operate in isolation; adjusting one will often require compensating with another.

The Gas Mixture: Carbon Source and Etching Agent

The process typically uses a mixture of a carbon-source gas (like methane, CH₄) and a large excess of hydrogen (H₂).

The hydrogen is not merely a carrier gas. It plays a active role by selectively etching away non-diamond carbon phases (like graphite), ensuring that the more stable diamond crystal structure is what predominantly grows on the substrate. The ratio of methane to hydrogen is therefore a critical lever for controlling quality.

Substrate Temperature: The Foundation for Crystallization

The temperature of the substrate, typically ranging from 700°C to 1100°C, directly governs the surface chemistry and atom mobility.

An optimal temperature window is required for the carbon species to arrange themselves into the diamond lattice. If the temperature is too low, growth is slow and may be amorphous. If it is too high, the formation of non-diamond carbon can increase, degrading the film's quality.

Chamber Pressure: Controlling Plasma Density

The pressure inside the deposition chamber influences the density of the plasma and the mean free path of the reactive species.

Higher pressures can increase the concentration of active radicals, potentially accelerating the growth rate. However, maintaining a stable, low-pressure environment is often key to creating a uniform plasma and, subsequently, a more homogenous and high-purity film.

Microwave Power: Energizing the Plasma

The microwave power level dictates the energy and density of the plasma. The power must be sufficient to effectively dissociate the hydrogen and methane molecules into the reactive atomic species required for diamond growth.

Higher power levels can increase plasma density and lead to faster growth rates. However, stability is paramount. The MPCVD method's advantage lies in its ability to generate a stable, high-density plasma without direct electrode contact, minimizing film contamination.

Understanding the Critical Trade-offs

Producing diamond film is a balancing act. Pushing for one attribute, like speed, often comes at the expense of another, such as purity.

Growth Rate vs. Crystal Quality

This is the most significant trade-off in diamond synthesis. Conditions that favor very high growth rates (e.g., higher methane concentration or pressure) often lead to a higher density of defects and impurities in the crystal lattice.

For high-precision applications like semiconductors or optics, a slower, more controlled growth process is necessary to achieve the required low defect density and high purity. Faster-growing films are often less homogeneous and may be limited to smaller areas.

Purity vs. Process Complexity

The highest quality films, required for power devices and advanced optical components, demand exceptional purity. This goes beyond just the process gas.

It requires the use of high-purity raw materials and a highly reliable, leak-free vacuum system to prevent contamination from atmospheric gases like nitrogen. This adds complexity and cost but is non-negotiable for achieving peak performance characteristics like high thermal conductivity and low dielectric loss.

How to Optimize for Your Goal

Your specific application determines how you should balance these parameters. There is no single "best" recipe, only a recipe that is best for your objective.

- If your primary focus is ultimate purity for semiconductors or optics: Prioritize a stable, lower-pressure process with a high-purity gas mixture and a robust vacuum system. Accept a slower growth rate as a necessary compromise for superior crystal quality and low defect density.

- If your primary focus is thick coatings for thermal management or tools: You can push for higher growth rates by carefully increasing methane concentration or microwave power. However, you must actively monitor film uniformity using methods like Raman spectroscopy to ensure quality does not fall below your required threshold.

- If your primary focus is reproducibility and cost-effectiveness: Leverage the inherent stability of the MPCVD process. Once you find a parameter set that meets your needs, focus on maintaining it with precision to ensure consistent, repeatable results from run to run.

Mastering MPCVD is about methodically controlling this system of variables to consistently produce diamond tailored to your specific need.

Summary Table:

| Parameter | Key Influence on Diamond Film | Typical Range/Example |

|---|---|---|

| Gas Mixture (CH₄/H₂) | Controls carbon supply & etches non-diamond phases | ~1-5% Methane in Hydrogen |

| Substrate Temperature | Governs crystal structure & atom mobility | 700°C - 1100°C |

| Chamber Pressure | Affects plasma density & film uniformity | Low-pressure for high purity |

| Microwave Power | Energizes plasma for growth rate & stability | Varies by system design |

Achieve Your Specific Diamond Film Goals with KINTEK

Whether your application demands ultimate purity for semiconductors, thick coatings for thermal management, or cost-effective reproducibility, mastering the delicate balance of MPCVD parameters is essential.

KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including robust CVD/PECVD Systems designed for precise control. Our strong deep customization capability allows us to tailor systems to your unique experimental requirements, helping you optimize the trade-off between growth rate and crystal quality.

Let's discuss how we can help you consistently produce high-quality diamond film.

Contact our experts today to explore a solution tailored for your success.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the MPCVD method and why is it considered effective for diamond deposition? Superior Purity & High Growth Rates

- How does MPCVD compare to other CVD techniques like HFCVD and PECVD? Discover the Best for High-Purity Films

- How is the substrate temperature controlled in the MPCVD equipment? Achieve Superior Diamond & Crystal Growth

- Why is MPCVD considered versatile and important in multiple industries? Unlock Diamond's Potential

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- How does MPCVD benefit the semiconductor industry? Unlock High-Power, High-Frequency Device Performance

- What factors influence the quality of diamond deposition in the MPCVD method? Master the Critical Parameters for High-Quality Diamond Growth

- What are the key benefits of MPCVD across various applications? Achieve Superior Material Performance