At its core, a CVD tube furnace provides operational benefits that center on precision, efficiency, and versatility. The design delivers exceptional temperature uniformity for reliable results, reduces energy consumption through rapid heating and cooling cycles, and offers the flexibility to handle a wide range of materials and processes in both laboratory and industrial settings.

The true value of a CVD tube furnace isn't just its ability to reach high temperatures. It's the operational control it provides, ensuring that processes are not only efficient and cost-effective but also highly repeatable and precise.

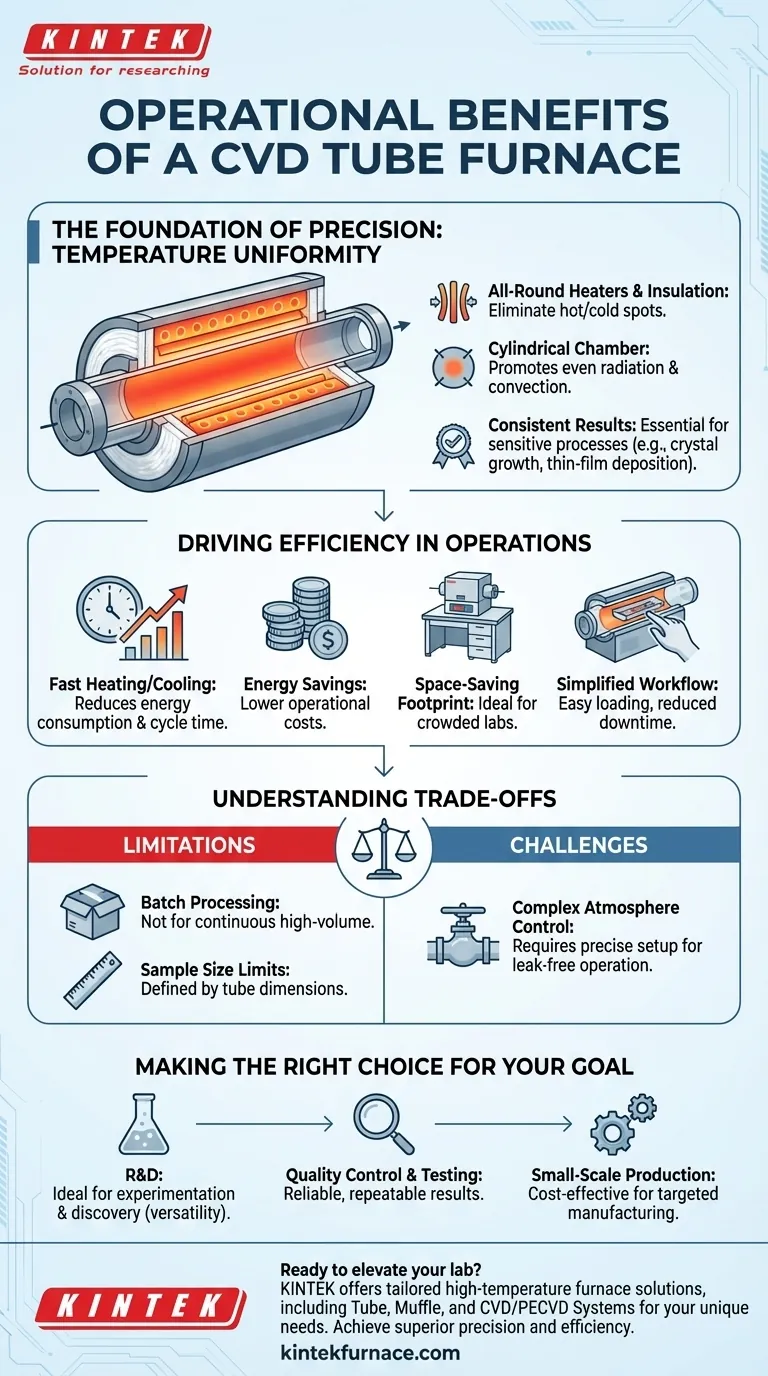

The Foundation of Precision: Temperature Uniformity

One of the most critical operational benefits is the ability to create an exceptionally uniform temperature zone. This is the cornerstone of achieving consistent and repeatable results.

How Uniformity is Achieved

A CVD tube furnace uses powerful, all-round heaters that encircle the process tube. This design, combined with high-quality alumina fiber insulation, minimizes heat loss and eliminates hot or cold spots within the central heating zone.

The Impact on Results

This precise thermal environment ensures that every part of a sample is subjected to the exact same temperature conditions. This is non-negotiable for sensitive processes like crystal growth, thin-film deposition, and material synthesis, where slight variations can ruin an entire batch.

The Role of Chamber Design

The typically cylindrical or semi-cylindrical chamber is engineered specifically for this purpose. Its shape promotes even radiation and convection, allowing for both efficient heating and rapid cooling of the materials inside.

Driving Efficiency in Your Operations

Beyond precision, a tube furnace is designed to optimize resources, from energy and lab space to operator time.

Energy Savings Through Design

Modern tube furnaces feature fast heating and cooling rates. This ability to reach and descend from setpoint temperatures quickly means the furnace consumes energy for shorter periods, directly reducing operational costs compared to larger, slower equipment.

Space-Saving Footprint

The compact, horizontal design is a significant advantage in crowded laboratories or facilities with limited floor space. It offers the high-temperature capabilities of much bulkier equipment without the associated spatial overhead.

Simplified Workflow

The horizontal orientation allows for easy loading and unloading of samples. This straightforward process reduces setup time, minimizes the risk of damaging delicate samples, and decreases operational downtime between experiments or production runs.

Understanding the Trade-offs

While highly effective, the design of a tube furnace presents certain operational trade-offs that are important to consider. Objectivity requires acknowledging these limitations.

Batch vs. Continuous Processing

By their nature, tube furnaces are inherently batch-processing systems. This makes them ideal for research, testing, or specialized small-scale production, but less suitable for high-volume, continuous manufacturing lines that require a constant flow of material.

Sample Size and Throughput Limitations

The physical dimensions of the process tube—its diameter and length—define the maximum sample size and batch throughput. While scalable to a degree, they cannot accommodate the very large or irregularly shaped components that a box or chamber furnace might handle.

Complexity of Atmosphere Control

Achieving a perfectly controlled, leak-free atmosphere for sensitive CVD processes requires careful setup. Maintaining gas purity and flow rates demands precise monitoring and well-maintained seals and connections, adding a layer of operational complexity.

Making the Right Choice for Your Goal

To determine if a CVD tube furnace is the right tool, align its core benefits with your primary objective.

- If your primary focus is research and development: The combination of precise temperature control and process versatility makes it an ideal instrument for experimentation and discovery.

- If your primary focus is quality control and testing: The exceptional temperature uniformity ensures that your tests are repeatable and your results are reliable for consistent product validation.

- If your primary focus is small-scale, specialized production: Its energy efficiency, rapid cycling, and suitability for periodic operations offer a cost-effective solution for targeted manufacturing.

Ultimately, understanding these operational characteristics empowers you to select the right tool for the job.

Summary Table:

| Operational Benefit | Key Features | Impact |

|---|---|---|

| Precision Temperature Control | All-round heaters, alumina fiber insulation, cylindrical chamber | Ensures uniform heating for consistent, repeatable results in processes like crystal growth and thin-film deposition |

| Energy Efficiency | Fast heating/cooling rates, compact design | Reduces operational costs and saves lab space |

| Process Versatility | Handles various materials, easy sample loading | Ideal for R&D, quality control, and small-scale production with flexible workflows |

| Trade-offs | Batch processing, limited sample size, complex atmosphere control | Best for research and specialized applications, not high-volume continuous manufacturing |

Ready to elevate your laboratory's capabilities with a tailored CVD tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet your unique experimental needs with strong deep customization. Whether you're in research, quality control, or small-scale production, we can help you achieve superior precision, efficiency, and results. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials