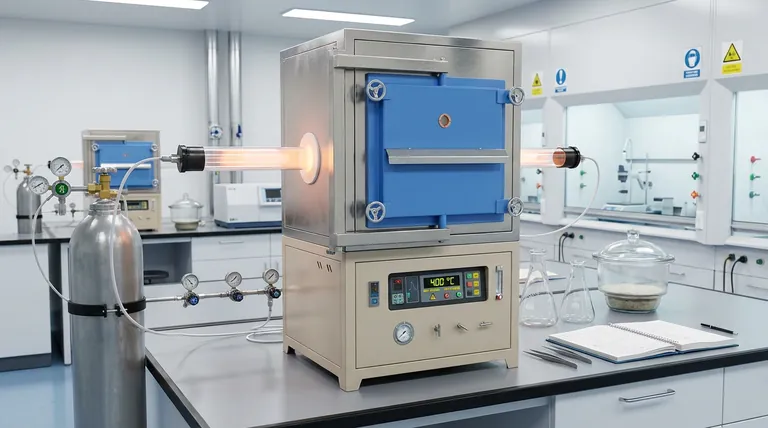

To successfully treat polyimide precursors, a tube furnace must provide a strictly controlled nitrogen protective atmosphere and high-precision programmed heating specifically between 350 °C and 450 °C. These conditions are non-negotiable for inducing the chemical changes required to create high-quality TR-PBO (Thermally Rearranged Polybenzoxazole) membranes.

The core function of the tube furnace is not merely to heat the material, but to induce irreversible intramolecular cyclodecarboxylation. By strictly controlling the thermal profile and environment, the furnace allows for the accurate regulation of free volume distribution, which ultimately defines the membrane's performance.

The Necessity of Atmosphere Control

Preventing Material Degradation

The thermal treatment of polyimide precursors requires high temperatures that would normally destroy organic materials.

A tube furnace addresses this by providing a sealed, strictly controlled nitrogen protective atmosphere.

Ensuring Chemical Specificity

By eliminating oxygen, the furnace ensures that the energy applied drives the specific rearrangement reaction rather than combustion or oxidation.

This protective environment is essential for maintaining the integrity of the carbon framework during the transformation process.

Precision Heating and Structural Engineering

Driving the TR Reaction

The conversion to TR-PBO is a chemical process called thermal rearrangement (TR).

This reaction relies on a specific temperature window, typically ranging from 350 °C to 450 °C.

The tube furnace utilizes high-precision programmed heating to reach and maintain these temperatures, ensuring the precursor undergoes the necessary irreversible changes.

Regulating Free Volume

The physical properties of the final membrane depend heavily on how the heat is distributed.

The furnace's precise heat distribution allows for the accurate regulation of free volume distribution within the membrane.

This "free volume" refers to the microscopic voids created when groups (like CO2) are removed from the polymer chain, which is critical for the membrane's filtration capabilities.

Understanding the Trade-offs

The Risk of Irreversibility

The process induced by the tube furnace—intramolecular cyclodecarboxylation—is irreversible.

Because the chemical structure is permanently altered, there is no room for error in the heating program.

Sensitivity to Thermal Fluctuations

While the furnace aims for precision, the material is highly sensitive to deviations.

If the temperature is too low (below 350 °C), the rearrangement will not occur effectively; if uncontrolled or excessive, it may compromise the mechanical stability of the membrane.

Achieving Optimal Membrane Properties

If your primary focus is Chemical Conversion:

- Ensure the furnace maintains a strict 350 °C to 450 °C range to guarantee the complete cyclodecarboxylation of ortho-substituted polyimides.

If your primary focus is Pore Structure:

- Prioritize the precision of the programmed heating ramp, as this dictates the free volume distribution and final permeability of the membrane.

Success in fabricating TR-PBO membranes relies entirely on the rigorous stability of the thermal and atmospheric environment provided by the furnace.

Summary Table:

| Critical Condition | Requirement | Purpose in TR-PBO Fabrication |

|---|---|---|

| Atmosphere | Sealed Nitrogen (O2-free) | Prevents oxidation; ensures chemical specificity |

| Temperature Range | 350 °C – 450 °C | Drives irreversible intramolecular cyclodecarboxylation |

| Heating Control | High-precision Programmed Ramp | Regulates free volume distribution and pore structure |

| Process Nature | Irreversible Reaction | Permanent structural alteration of the carbon framework |

Optimize Your Membrane Research with KINTEK Precision

Don't let thermal fluctuations compromise your material integrity. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed to meet the rigorous demands of polyimide precursor treatment. Backed by expert R&D and manufacturing, our lab high-temp furnaces are fully customizable to ensure your TR-PBO membranes achieve optimal permeability and structural precision.

Ready to elevate your thermal processing? Contact us today for a custom solution!

References

- Mario Rojas-Rodríguez, Carla Aguilar‐Lugo. Thermally Rearranged (TR) Polybenzoxazoles from <i>o</i>-Substituted Precursor Polyimides with Phenyl Pendant Groups: Synthesis, Properties, and Thermal Rearrangement Conditions. DOI: 10.1021/acs.macromol.4c00169

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role do multi-component mass flow controllers play in tube furnace nitrogen studies? Precise Gas Control for NOx.

- Why must catalysts undergo reduction in a tube furnace? Master Your Furfural Hydrogenation Preparation

- What are the primary functions of a tube furnace during GO thermal reduction? Optimize Graphene Conductivity

- How do three-zone tube furnaces contribute to energy and resource efficiency? Boost Lab Performance with Precision Heating

- How can tube furnaces be enhanced with multiple heating zones and what benefits does this provide? Unlock Precise Temperature Control

- What are the primary uses of tube furnaces in academic and industrial settings? Unlock Precision Thermal Processing

- Why is a high-temperature tubular furnace required for the activation process of walnut shell activated carbon at 700°C?

- How does the industrial tube furnace contribute to Fe-N-C catalyst synthesis? Master High-Temperature Carbonization