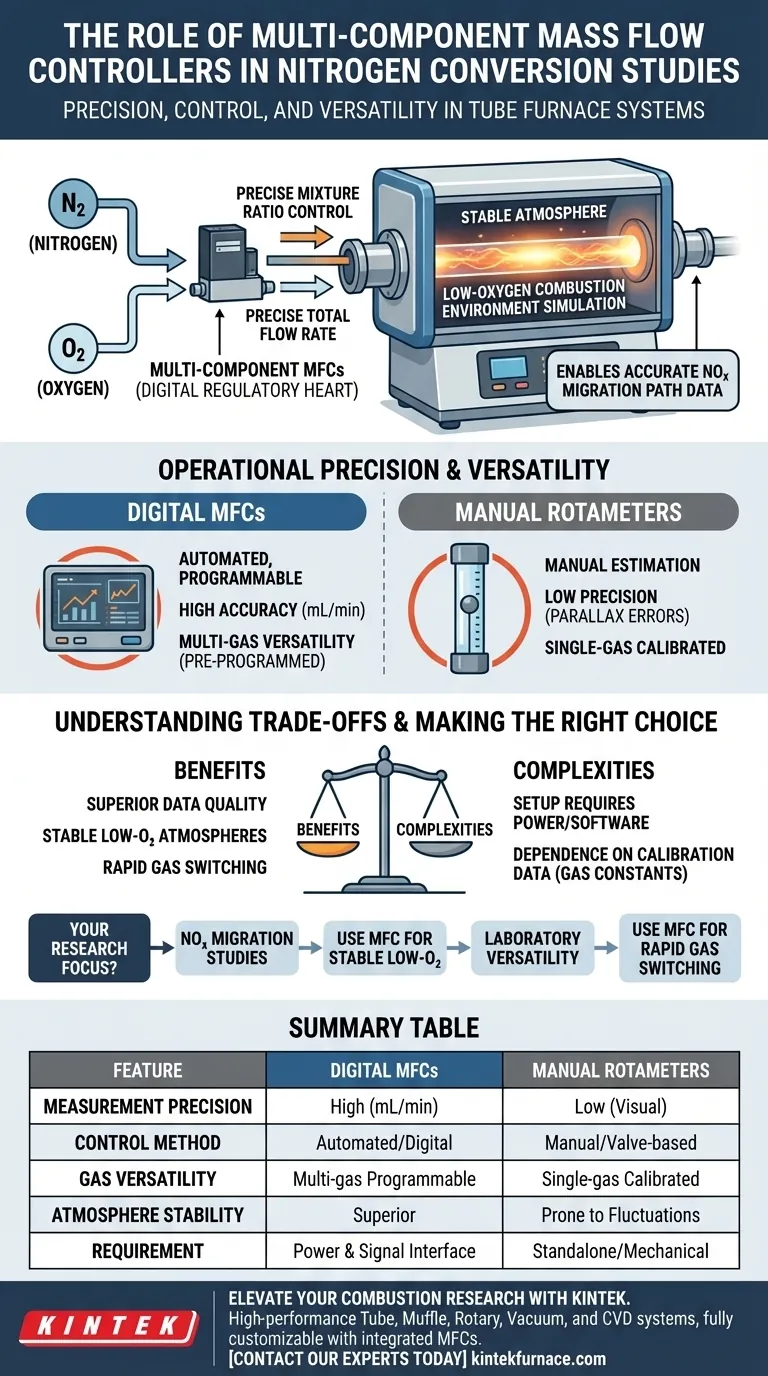

Multi-component mass flow controllers (MFCs) serve as the regulatory heart of tube furnace systems during nitrogen conversion studies. Their primary role is to rigorously control the mixture ratio of input gases—typically nitrogen and oxygen—while simultaneously maintaining a precise total gas flow rate. This dual regulation is the prerequisite for establishing the stable, reproducible atmospheres necessary for scientific analysis.

By automating the precise delivery of gas mixtures, multi-component MFCs enable researchers to simulate specific low-oxygen combustion environments with high fidelity, ensuring that data regarding NOx migration paths is both accurate and reproducible.

Simulating Real-World Combustion Environments

To study nitrogen conversion effectively, you cannot rely on approximate environments; you must recreate specific physical conditions.

Controlling Mixture Ratios

The core function of these controllers is to govern the proportion of gases entering the furnace.

By adjusting the ratio of nitrogen to oxygen, the system creates a custom atmosphere. This is essential for isolating variables in combustion research.

Replicating Low-Oxygen Conditions

Researching NOx migration paths often requires simulating oxygen-deficient scenarios.

High-precision MFCs allow you to dial in these specific "starved" environments. This capability provides the stable reaction atmosphere needed to observe how nitrogen behaves under stress, without the interference of fluctuating gas concentrations.

Operational Precision and Versatility

Beyond the chemistry, the use of digital MFCs introduces a layer of operational rigor that manual methods cannot match.

Digital Accuracy vs. Manual Estimation

Unlike simple ball-type flow meters (rotameters), digital MFCs offer precision often measured in milliliters per minute.

Ball-type meters require manual reading and are prone to parallax errors. Digital controllers eliminate this ambiguity, ensuring the flow rate requested is exactly the flow rate delivered.

Programmability for Multiple Gases

A significant advantage of modern digital MFCs is their versatility in a laboratory setting.

While mechanical meters must often be physically calibrated or swapped for each specific gas, digital MFCs can be pre-programmed for a wide range of gases. This allows a single unit to manage different inputs effectively, streamlining the setup for complex multi-gas experiments.

Understanding the Trade-offs

While mass flow controllers are superior for research-grade data, they introduce specific complexities that must be managed.

Complexity of Setup

MFCs are not "plug and play" in the same way a manual valve is. They require power supplies, signal cables, and often a software interface or readout display to operate.

Dependence on Calibration Data

Although digital MFCs are versatile, their accuracy relies on the correctness of the gas properties programmed into them.

If the gas constant selected in the software does not match the actual gas being used, the thermal properties will differ, leading to measurement errors. The user must ensure the controller is set to the correct gas mode before beginning the experiment.

Making the Right Choice for Your Research

Your decision to implement multi-component MFCs should be driven by the specific demands of your data.

- If your primary focus is NOx Migration Studies: You must use an MFC to guarantee the stable, low-oxygen environment required to validate migration paths.

- If your primary focus is Laboratory Versatility: You should utilize digital MFCs to allow for rapid switching between different gas types without purchasing new hardware for every experiment.

Precision in gas delivery is the difference between an estimated guess and a scientifically valid conclusion.

Summary Table:

| Feature | Digital MFCs | Manual Rotameters |

|---|---|---|

| Measurement Precision | High (milliliters per minute) | Low (visual estimation) |

| Control Method | Automated/Digital | Manual/Valve-based |

| Gas Versatility | Multi-gas programmable | Single-gas calibrated |

| Atmosphere Stability | Superior (for NOx studies) | Prone to fluctuations |

| Requirement | Power & Signal Interface | Standalone/Mechanical |

Elevate Your Combustion Research with KINTEK

Precise gas delivery is the foundation of scientifically valid NOx migration studies. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable with integrated multi-component mass flow controllers to meet your unique laboratory needs.

Don't settle for manual estimation. Ensure your data is accurate and reproducible with our precision-engineered high-temperature furnace solutions. Contact our technical experts today to build the perfect system for your research.

Visual Guide

References

- Silin Zeng, Baosheng Jin. Experimental study on No<sub>x</sub> emission and nitrogen conversion characteristics of a coal gangue blended with coal washing mixture. DOI: 10.1088/1742-6596/3013/1/012035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a quartz tube furnace play in the carbonization of nitrogen-doped carbon? Optimize Your Material Synthesis

- What is the intended use of the 3-Zone tube furnace? Achieve Precise Thermal Control for Advanced Materials

- How does a high-temperature tube furnace facilitate the conversion of Cu@ZIF-8? Master Precision Material Synthesis

- Why is a high-temperature tube furnace required for LNMO synthesis? Achieve Precise Fd-3m Spinel Structures

- How does a three-zone tube furnace facilitate the synthesis of germanium nanowires? Achieve High-Quality SVG Results

- How does the vacuum environment in a tube furnace benefit material processing? Achieve Purity and Performance

- How does a vacuum tube furnace work? Master Precise High-Temp Material Processing

- What are the technical advantages of using a three-zone tube furnace? Boost SnSe Thin Film Quality