The role of a quartz tube furnace in carbonization is to provide a strictly controlled reaction environment defined by inert atmosphere regulation and precise thermal programming. Specifically, it enables the heating of precursors to high temperatures (typically around 750°C) under a flow of argon gas, which facilitates the decomposition of organic materials and the subsequent recombination of nitrogen and carbon atoms onto templates without the risk of oxidation.

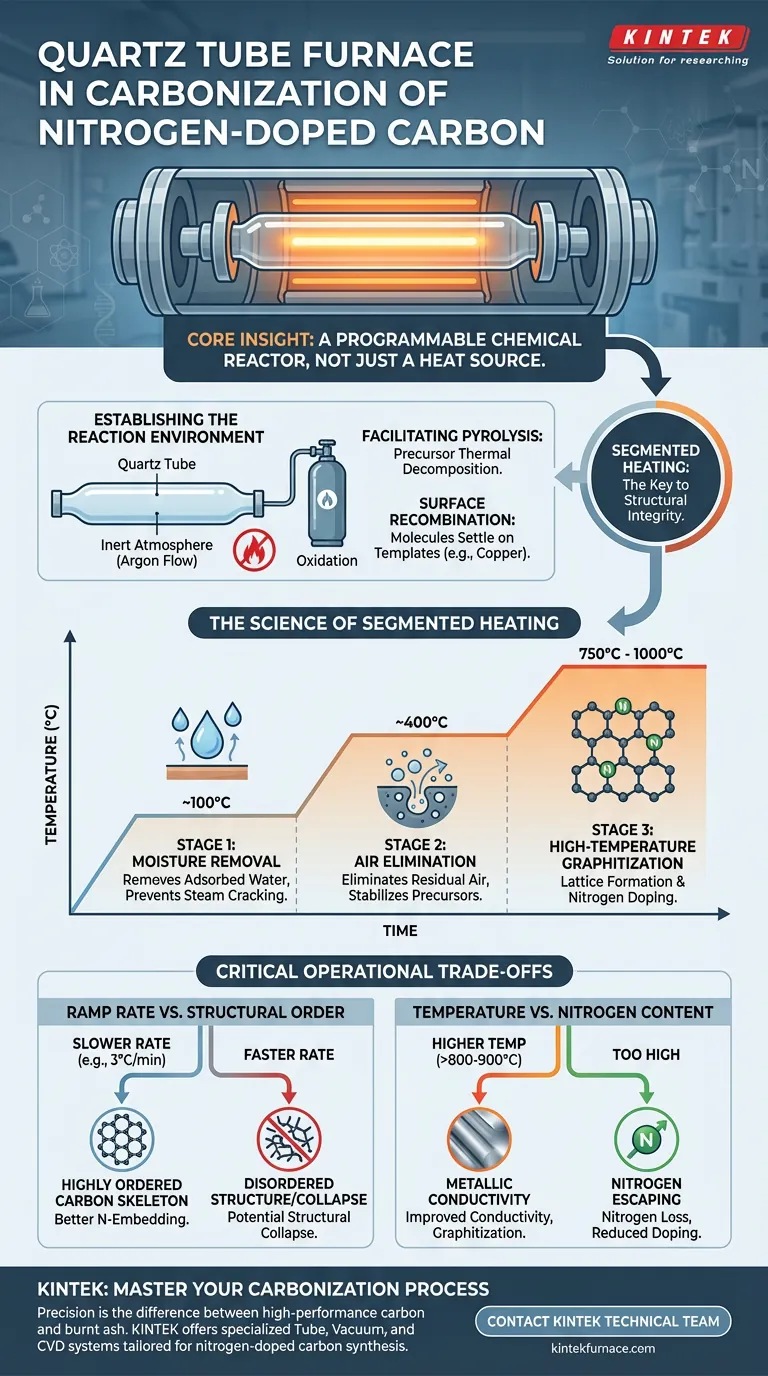

Core Insight: The quartz tube furnace acts as a programmable chemical reactor, not just a heat source. Its primary value lies in "segmented heating"—the ability to hold specific lower temperatures to remove water and residual air before ramping up to the critical carbonization threshold, ensuring the structural integrity of the final nitrogen-doped material.

Establishing the Reaction Environment

The Necessity of an Inert Atmosphere

The fundamental role of the quartz tube furnace is to isolate the reaction from the ambient environment. Carbonization requires high thermal energy, but in the presence of oxygen, carbon precursors would simply burn (oxidize) into ash and gas.

Facilitating Precursor Decomposition

By maintaining a continuous flow of inert gas, such as argon, the furnace creates a protective zone. This allows organic precursors to undergo pyrolysis—thermal decomposition—rather than combustion.

Surface Recombination on Templates

The controlled environment allows decomposed molecules to settle and recombine on specific substrates, such as copper templates. This is critical for shaping the physical structure of the resulting carbon.

The Science of Segmented Heating

Stage 1: Moisture Removal

A standard furnace simply heats up; a quartz tube furnace enables complex heating profiles. The first critical segment often involves holding the temperature at approximately 100°C.

This step ensures the complete removal of physically adsorbed water from the precursor materials, preventing steam formation that could crack the material structure later.

Stage 2: Elimination of Residual Air

Before reaching peak temperatures, the furnace can be programmed to hold at an intermediate stage, such as 400°C.

This phase is crucial for eliminating any residual air trapped within the pores of the material. It stabilizes the precursors chemically before the final transformation begins.

Stage 3: High-Temperature Graphitization

The final stage involves ramping to the target carbonization temperature, typically 750°C (though this can range from 700°C to 1000°C depending on the specific goal).

At this thermal plateau, the carbon atoms rearrange into a stable lattice, and nitrogen atoms are permanently locked (doped) into the carbon skeleton, imparting the desired electrochemical properties.

Critical Operational Trade-offs

Ramp Rate vs. Structural Order

The speed at which the furnace increases temperature (the ramp rate) is a major variable. A slower rate (e.g., 3°C/min) generally leads to a more ordered carbon skeleton and better nitrogen embedding.

However, extremely slow rates increase energy consumption and process time. Conversely, heating too quickly can cause the structural collapse of the carbon framework or the rapid loss of nitrogen content as volatile gas.

Temperature vs. Nitrogen Content

There is an inherent trade-off in temperature selection. Higher temperatures (above 800-900°C) improve conductivity and graphitization (making the material more "metal-like").

However, excessively high temperatures can destabilize the nitrogen bonds, causing the nitrogen to escape the lattice and reducing the doping level. The quartz tube furnace allows you to dial in the exact compromise needed for your application.

Making the Right Choice for Your Goal

To maximize the effectiveness of your carbonization process, tailor the furnace programming to your specific objectives:

- If your primary focus is Structural Integrity: Prioritize a multi-stage heating profile (100°C then 400°C holds) to ensure gentle degassing and prevent cracking.

- If your primary focus is Doping Efficiency: Utilize a strictly controlled, slow ramp rate to the target temperature (e.g., 750°C) to maximize the ordered embedding of nitrogen atoms into the carbon lattice.

Success in nitrogen-doped carbon synthesis relies less on maximum heat and more on the precision of your thermal roadmap.

Summary Table:

| Process Stage | Temperature | Primary Function |

|---|---|---|

| Stage 1: Moisture Removal | ~100°C | Removes adsorbed water to prevent structural cracking. |

| Stage 2: Air Elimination | ~400°C | Stabilizes precursors and eliminates residual trapped air. |

| Stage 3: Graphitization | 750°C - 1000°C | Enables lattice formation and nitrogen atom embedding. |

| Atmosphere Control | N/A | Argon flow prevents oxidation and facilitates pyrolysis. |

Master Your Carbonization Process with KINTEK

Precision is the difference between high-performance carbon and burnt ash. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems designed for the rigorous demands of nitrogen-doped carbon synthesis.

Whether you require customizable heating profiles for structural integrity or high-temp stability for graphitization, our lab solutions are tailored to your unique research needs. Contact our technical team today to find the perfect furnace for your laboratory and elevate your material science outcomes.

Visual Guide

References

- Samantha N. Lauro, C. Buddie Mullins. Copper shape-templated N-doped carbons: exercising selective surface area control for lithium-ion batteries & beyond. DOI: 10.1039/d4ta00427b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What makes the multi gradient experimental tube furnace capable of creating temperature gradients? Unlock Precise Thermal Control for Your Experiments

- How to use a tubular furnace? Master Precise Temperature Control for Your Lab

- What role does a tube furnace play in the pyrolysis of oil shale? Mastering Kerogen Conversion & Yield

- Why is a high-precision dual-zone furnace required for 1T-TaS2 crystals? Achieve Perfect CVT Phase Integrity

- What types of atmospheres can a horizontal electric furnace control? Master Material Processing with Precision

- How does a tube furnace facilitate the activation and shaping of NiCoO2 nanowires? Optimize Your Catalyst Performance

- What are the benefits of using tube furnaces in industrial processes? Achieve Precision and Control for Your Lab

- Why is a high-precision programmable tube furnace required for N-doped TiO2@C composites? Expert Thermal Solutions