In short, three-zone tube furnaces enhance efficiency through a combination of superior thermal management and intelligent process control. By dividing the heating chamber into three distinct, independently controlled areas, they achieve precise temperature uniformity, which minimizes both direct energy consumption and indirect resource waste from failed processes.

The core value of a three-zone furnace is not just saving electricity; it's about achieving a higher level of process control. This precision leads to better results, less material waste, and more efficient use of lab time, creating a cascading effect of resource efficiency.

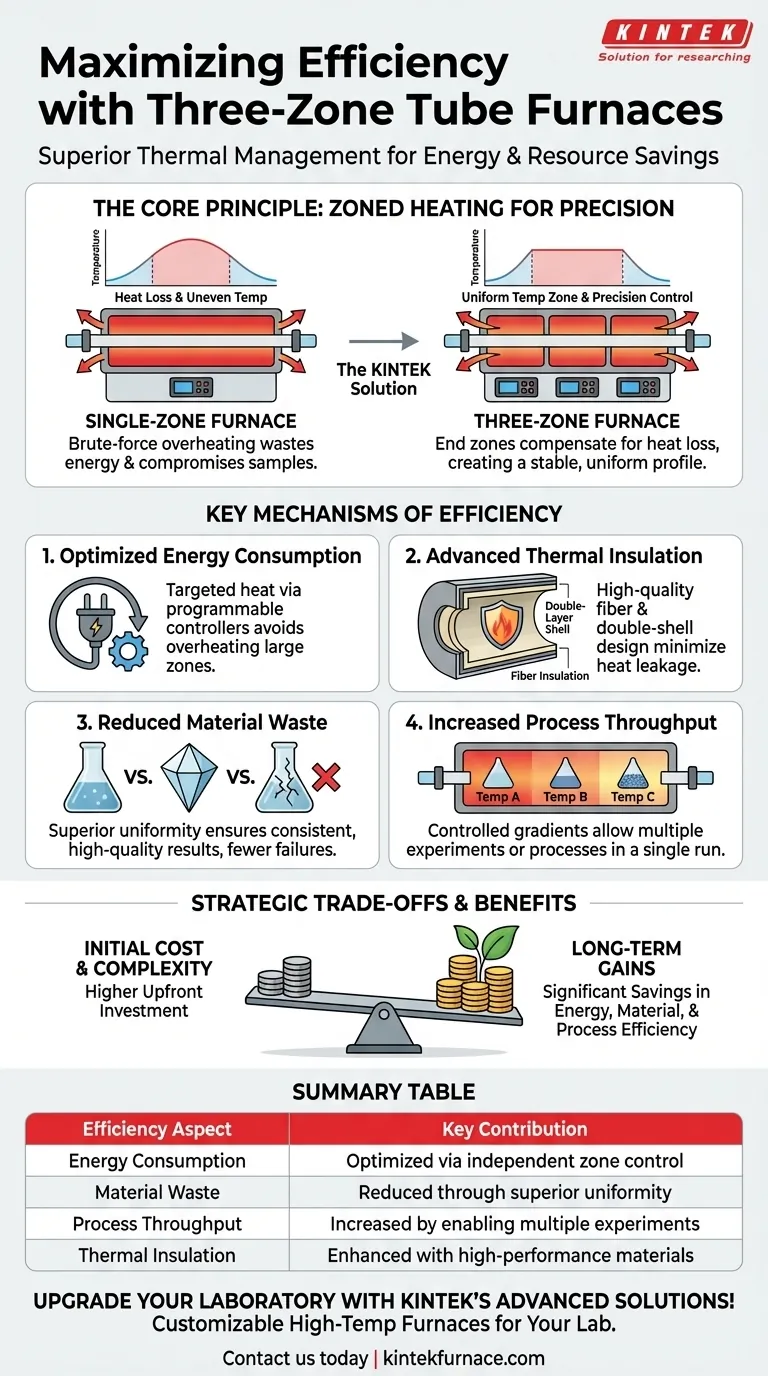

The Core Principle: Zoned Heating for Precision Control

The primary advantage of a three-zone furnace stems from its ability to counteract a fundamental problem in thermal processing: heat loss.

The Challenge with Single-Zone Furnaces

In a standard single-zone furnace, a single heating element surrounds the process tube. This design inevitably creates a temperature gradient, where the center is hottest and the ends are cooler due to natural heat loss to the surrounding environment.

To achieve a desired temperature over a sample of any significant length, the operator must often overheat the center zone. This is a brute-force approach that wastes energy and can compromise the integrity of the sample.

How Three Zones Create Uniformity

A three-zone furnace solves this problem by adding two smaller heating zones at either end of the main central zone.

Each zone has its own temperature sensor and controller. The end zones are programmed to a slightly higher temperature to precisely compensate for heat loss, effectively creating a much longer, more stable, and highly uniform flat temperature zone across the entire furnace.

Key Mechanisms of Energy & Resource Efficiency

The design of a three-zone furnace directly translates into measurable efficiency gains through several key mechanisms.

1. Optimized Energy Consumption

By targeting heat only where it's needed, the furnace avoids the waste associated with overheating a single large zone. The programmable controllers ensure each of the three zones uses the minimum energy required to maintain the desired thermal profile.

2. Advanced Thermal Insulation

Modern furnaces incorporate high-performance insulation materials, such as high-quality polycrystalline mullite fiber. This material enables rapid heating while minimizing heat leakage.

Features like double-layer furnace shells and advanced air insulation technology further contain thermal energy, reducing the power needed to hold a setpoint temperature for extended periods.

3. Reduced Material Waste

The superior temperature uniformity is the single greatest contributor to resource efficiency. For sensitive processes like crystal growth, annealing, or chemical vapor deposition (CVD), precise temperature is critical.

By minimizing temperature deviations, three-zone furnaces produce more consistent, higher-quality results. This dramatically reduces the number of failed experiments or rejected parts, saving valuable materials, precursor chemicals, and substrates.

4. Increased Process Throughput

The independent zones offer unique flexibility. They can be programmed to create a controlled temperature gradient across the sample, allowing for multiple processes to be investigated in a single run.

This capability can effectively allow one furnace to do the work of several, increasing experimental throughput and reducing errors associated with transferring samples between different pieces of equipment.

Understanding the Trade-offs

While highly efficient, a three-zone furnace is not the default choice for every application. Understanding its limitations is crucial for making a sound investment.

Increased Cost and Complexity

The primary trade-off is upfront cost. The additional heating elements, thermocouples, and sophisticated controllers make a three-zone furnace significantly more expensive than its single-zone counterpart.

When a Single-Zone is Sufficient

For applications involving very small samples placed directly in the center of the furnace, or for processes that are not sensitive to minor temperature variations, the cost and complexity of a three-zone system may be unnecessary. A single-zone furnace can be a more cost-effective solution in these cases.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on the demands of your process.

- If your primary focus is process yield and sample quality: The superior temperature uniformity of a three-zone furnace is critical for reducing material waste and ensuring reproducible results.

- If your primary focus is energy savings on long-duration processes: The optimized zone control and advanced insulation will deliver significant operational cost reductions over the furnace's lifetime.

- If your primary focus is maximizing lab throughput and flexibility: The ability to run complex thermal profiles or create temperature gradients in a single instrument makes a three-zone furnace an invaluable tool.

Ultimately, choosing a three-zone furnace is a strategic decision to invest in precision, trading higher initial cost for significant long-term gains in energy, material, and process efficiency.

Summary Table:

| Efficiency Aspect | Key Contribution |

|---|---|

| Energy Consumption | Optimized via independent zone control and minimal overheating |

| Material Waste | Reduced through superior temperature uniformity for consistent results |

| Process Throughput | Increased by enabling multiple experiments in a single run |

| Thermal Insulation | Enhanced with high-performance materials to minimize heat loss |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision tools like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, enhancing efficiency and reducing waste. Contact us today to discuss how our solutions can transform your processes!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity