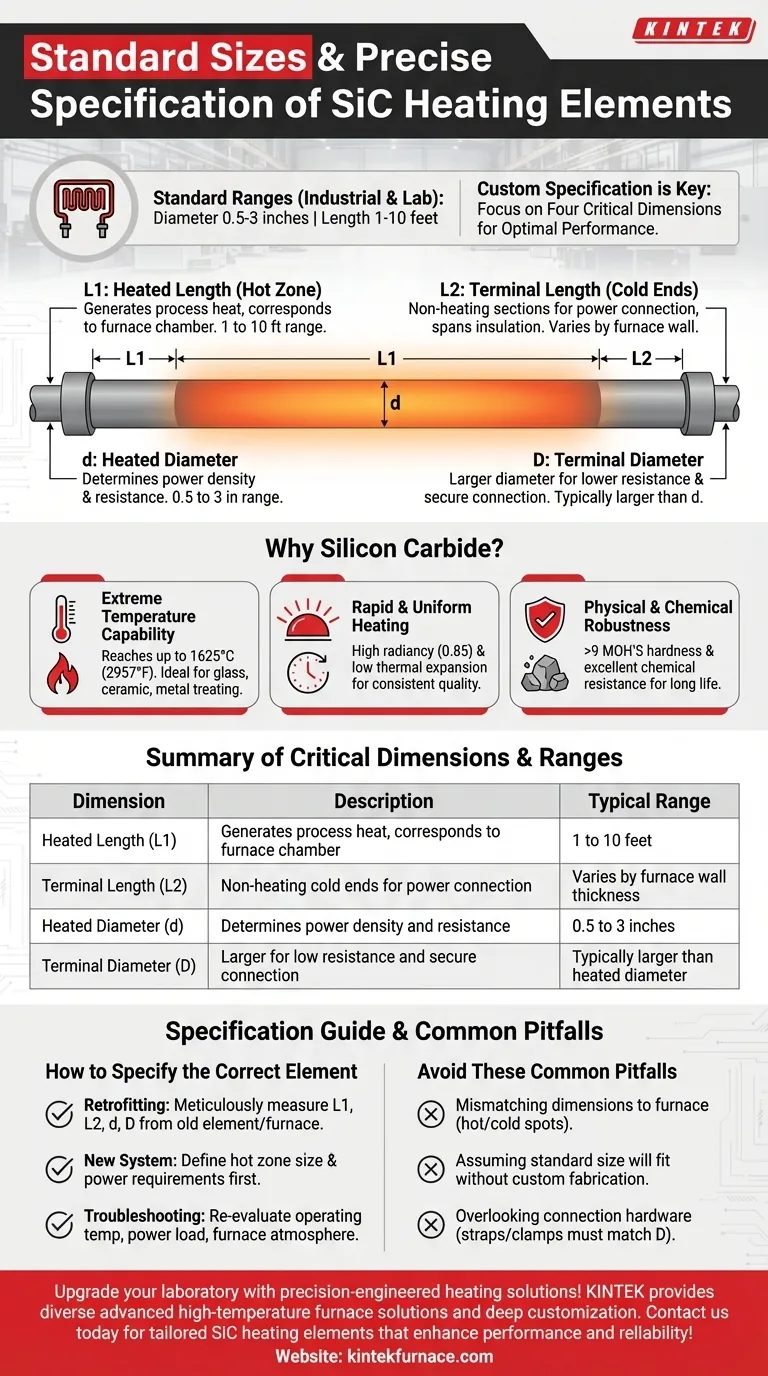

In industrial and laboratory settings, standard silicon carbide (SiC) heating elements typically range from 0.5 to 3 inches in diameter and 1 to 10 feet in length. While these off-the-shelf sizes cover many applications, they represent only the starting point for proper specification. Custom sizes and shapes are also commonly produced to meet precise furnace requirements.

Choosing the right heating element is less about finding a "standard size" and more about correctly specifying the four critical dimensions—heated length, terminal length, and their respective diameters—that match your furnace's geometry and power requirements.

Deconstructing the Four Critical Dimensions

The overall size of an SiC element is a combination of distinct sections that serve different functions. Misunderstanding these can lead to inefficient heating, damaged equipment, or premature element failure.

Heated Length (L1) and the Hot Zone

The heated length (L1), often called the hot zone, is the section of the element that actually generates the target process heat. This dimension must correspond directly to the width or height of your furnace chamber to ensure uniform heating.

Terminal Length (L2) and the Cold Ends

The terminal lengths (L2) are the non-heating sections at each end of the element. These "cold ends" pass through the furnace insulation and connect to the power supply. Their length must be sufficient to span the furnace wall thickness without overheating the terminals or surrounding area.

Heated Diameter (d) and Power Density

The diameter of the heated section (d) is a key factor in determining the element's power density and electrical resistance. A larger diameter generally allows for higher power output but must be matched to the power supply's capabilities.

Terminal Diameter (D) and Electrical Connection

The diameter of the terminal (D) is typically larger than the heated diameter to ensure lower electrical resistance in the cold ends. This design minimizes heat generation outside the furnace chamber and provides a robust physical connection point for straps and clamps.

Why Silicon Carbide is the Material of Choice

Understanding the inherent properties of SiC clarifies why precise dimensioning is so critical. These elements are chosen for demanding applications where performance and reliability are paramount.

Extreme Temperature Capability

Silicon carbide elements are capable of reaching element temperatures as high as 1625°C (2957°F). This allows them to operate effectively in applications like glass melting, ceramic firing, and metal heat treating.

Rapid and Uniform Heating

SiC has a high radiancy (0.85) and low thermal expansion, enabling it to heat up and cool down quickly while providing exceptionally uniform temperature distribution. This leads to consistent product quality and efficient energy use.

Physical and Chemical Robustness

With a hardness over 9 MOH'S and high bend strength, SiC elements are physically durable. They also possess excellent chemical resistance, allowing for a long service life even in challenging furnace atmospheres.

Common Pitfalls in Element Specification

A precise specification is the best defense against common operational issues. Focusing only on one or two dimensions while ignoring the others is a frequent source of problems.

Mismatching Dimensions to the Furnace

Ordering an element with an incorrect heated length (L1) results in hot or cold spots within the furnace. Similarly, an incorrect terminal length (L2) can cause the furnace casing to overheat or create a poor electrical connection.

Assuming a Standard Size Will Fit

While standard ranges exist, most industrial furnaces have unique dimensions. Always measure your existing elements or furnace chamber precisely rather than assuming a standard size is a direct replacement. Custom fabrication is a normal part of the industry.

Overlooking Connection Hardware

The electrical connection is a common failure point. The straps and clamps used to connect the element terminals to the power supply must be specified to match the terminal diameter (D) exactly to ensure a secure, low-resistance connection.

How to Specify the Correct Element

Use the following guidelines to ensure you select an element that delivers optimal performance and longevity for your specific application.

- If your primary focus is retrofitting an existing furnace: Meticulously measure all four key dimensions (L1, L2, d, D) from the old elements or the furnace itself before ordering.

- If your primary focus is designing a new system: Determine your required hot zone size and power requirements first, as these will dictate the necessary element configuration and dimensions.

- If your primary focus is troubleshooting premature failures: Re-evaluate the element's operating temperature, power load, and furnace atmosphere in addition to verifying the physical dimensions are correct for the installation.

Ultimately, providing a complete and accurate specification is the most critical step toward achieving reliable high-temperature process heating.

Summary Table:

| Dimension | Description | Typical Range |

|---|---|---|

| Heated Length (L1) | Generates process heat, corresponds to furnace chamber | 1 to 10 feet |

| Terminal Length (L2) | Non-heating cold ends for power connection | Varies by furnace wall thickness |

| Heated Diameter (d) | Determines power density and resistance | 0.5 to 3 inches |

| Terminal Diameter (D) | Larger for low resistance and secure connection | Typically larger than heated diameter |

Upgrade your laboratory with precision-engineered heating solutions! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today for tailored SiC heating elements that enhance performance and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C