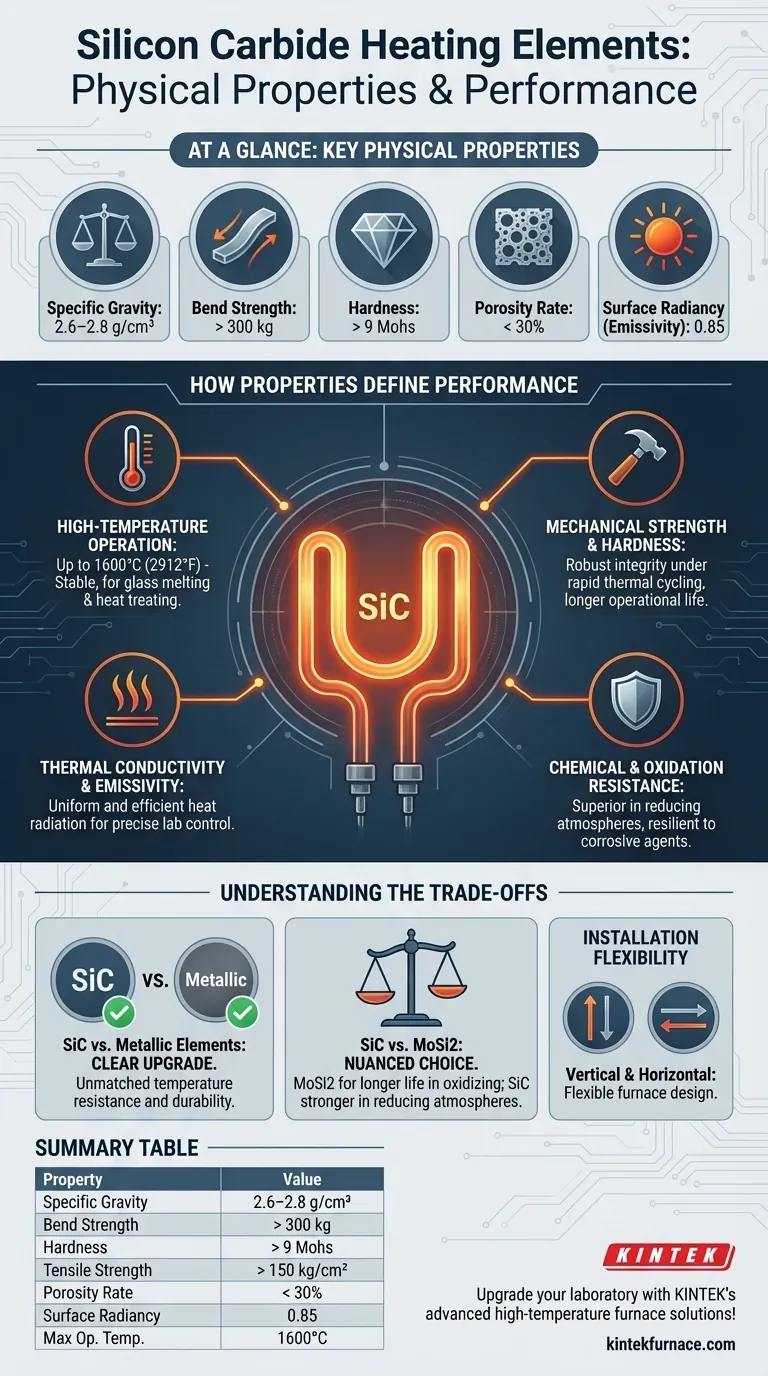

At a glance, the key physical properties of silicon carbide (SiC) heating elements include a specific gravity of 2.6–2.8 g/cm³, a bend strength over 300 kg, and a hardness exceeding 9 on the Mohs scale. These elements also exhibit a tensile strength over 150 kg/cm², a porosity rate under 30%, and a high surface radiancy (emissivity) of 0.85, which dictates their ability to radiate heat efficiently.

The exceptional physical properties of silicon carbide translate directly into high-temperature durability and performance. Understanding these properties is not just an academic exercise; it is the key to selecting the right heating element for a demanding industrial or laboratory environment.

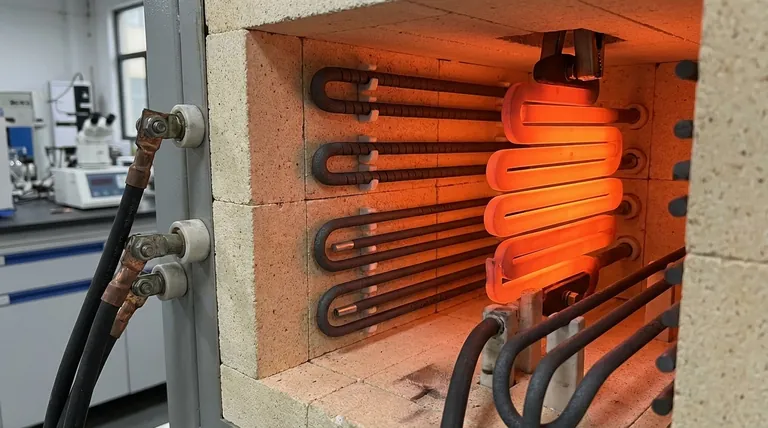

How Physical Properties Define Performance

The raw specifications of SiC elements directly explain their advantages in high-heat applications. Each property contributes to a specific performance characteristic that sets them apart from traditional metallic heaters.

High-Temperature Operation

Silicon carbide's inherent material stability allows it to operate at temperatures up to 1600°C (2912°F). This is far beyond the capability of most conventional metal heating elements, which would degrade or melt at these temperatures.

This property makes SiC essential for processes like glass melting, metal heat treating, and high-temperature laboratory research.

Mechanical Strength and Hardness

With a bend strength over 300 kg and a hardness over 9 MOH’S, SiC elements are physically robust. This high strength ensures they maintain their structural integrity even when subjected to the stress of rapid thermal cycling.

This durability means a longer operational life and less risk of mechanical failure compared to more fragile alternatives.

Thermal Conductivity and Emissivity

SiC possesses excellent thermal conductivity and a high radiancy of 0.85. This combination allows it to generate and radiate heat uniformly and efficiently.

For applications like laboratory furnaces, this leads to the precise temperature control and even heating zones required for reliable research and testing.

Chemical and Oxidation Resistance

Unlike many metals, silicon carbide offers superior resistance to oxidation and chemical corrosion at high temperatures. It is particularly stronger in reducing atmospheres compared to other high-temperature elements like Molybdenum Disilicide (MoSi2).

This chemical resilience makes SiC ideal for use in challenging industrial environments where corrosive agents may be present.

Understanding the Trade-offs

While SiC offers significant advantages, no material is perfect for every situation. A clear-eyed assessment of its limitations is crucial for making an informed decision.

SiC vs. Metallic Elements

For high-temperature applications, SiC is a clear upgrade. Traditional resistance heating elements simply cannot match its temperature resistance or durability in harsh conditions. The choice here is driven by the required operating temperature.

SiC vs. MoSi2 (Molybdenum Disilicide)

This is a more nuanced comparison. While SiC is extremely durable, MoSi2 heating elements often have a significantly longer lifespan, sometimes lasting one-third to one-half longer in certain conditions, particularly oxidizing atmospheres.

However, SiC maintains a strength advantage in reducing atmospheres, creating a critical performance trade-off depending on the furnace environment.

Installation and Design Flexibility

SiC elements, such as the common U-type rod, offer practical design advantages. They can be installed both vertically and horizontally, providing flexibility in furnace construction and making electrical connections straightforward.

Making the Right Choice for Your Application

Your specific goal will determine whether SiC is the optimal choice.

- If your primary focus is operating at extreme temperatures (up to 1600°C) with uniform heating: SiC is an excellent choice, especially for laboratory work and precision industrial processes.

- If your primary focus is achieving the absolute longest element lifespan in an oxidizing atmosphere: You should evaluate MoSi2, as it may offer a longer operational life in these specific conditions.

- If your primary focus is durability in a furnace with a reducing chemical atmosphere: SiC's superior strength in these environments makes it the more reliable option.

Ultimately, selecting the correct heating element is about matching the material's inherent properties to the demands of your application.

Summary Table:

| Property | Value |

|---|---|

| Specific Gravity | 2.6–2.8 g/cm³ |

| Bend Strength | > 300 kg |

| Hardness | > 9 Mohs |

| Tensile Strength | > 150 kg/cm² |

| Porosity Rate | < 30% |

| Surface Radiancy (Emissivity) | 0.85 |

| Max Operating Temperature | 1600°C (2912°F) |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements like silicon carbide, designed for durability and precision. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization to meet your unique experimental needs. Contact us today to enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency