In industrial heating, the primary benefit of molybdenum-based heating elements is their ability to perform reliably at extreme temperatures where many other materials fail. Molybdenum, and particularly molybdenum disilicide (MoSi2), provides a unique combination of high-temperature stability, resistance to oxidation, and operational longevity, making it a critical component for demanding processes in industries from ceramics to electronics.

The decision to use molybdenum heating elements is not just about reaching high temperatures. It is about achieving precise, repeatable, and efficient thermal control in aggressive industrial environments, which is fundamental to ensuring product quality and maximizing operational uptime.

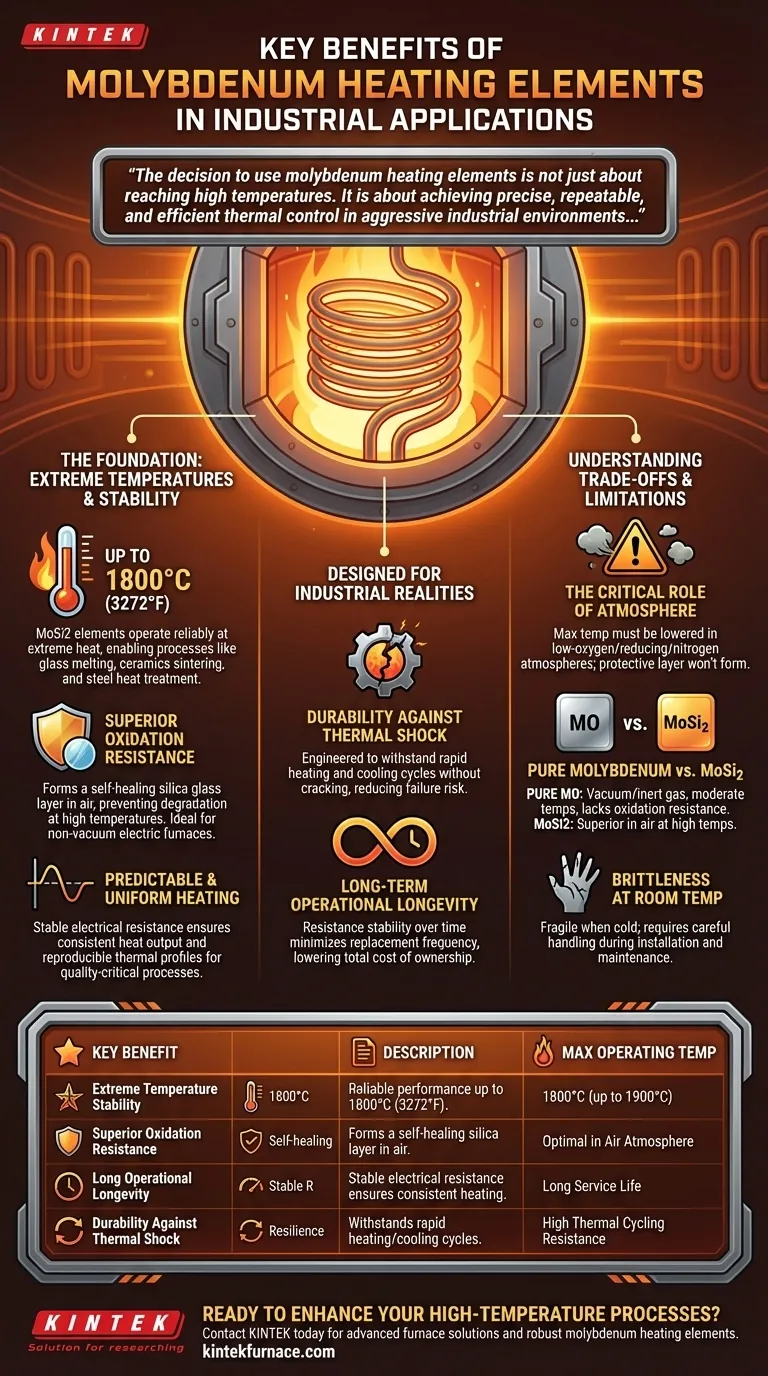

The Foundation: Unlocking High-Temperature Processes

The core advantage of molybdenum elements stems from their fundamental material properties. They enable industrial processes that are simply not possible with more common heating materials like nickel-chromium.

Extreme Operating Temperatures

Molybdenum disilicide (MoSi2) elements are engineered to operate reliably in furnace temperatures up to 1800°C (3272°F). Some specialized applications can even push peak operating temperatures toward 1900°C.

This capability is essential for melting glass, sintering advanced ceramics, growing crystals, and performing specialized heat treatments on steel that require intense and sustained heat.

Superior Oxidation Resistance

In a standard air atmosphere, MoSi2 elements form a protective, self-healing layer of silica glass on their surface at high temperatures. This layer acts as a barrier, preventing the underlying element from oxidizing and rapidly degrading.

This single characteristic is what makes MoSi2 the preferred choice for high-temperature electric furnaces that do not operate in a vacuum or inert gas environment.

Predictable and Uniform Heating

MoSi2 elements exhibit very stable electrical resistance over their lifespan. This means they deliver consistent, predictable heat output without significant aging effects.

For any quality-critical process, this stability ensures that the thermal profile remains the same from one batch to the next, guaranteeing product consistency.

Designed for Industrial Realities

Beyond pure temperature resistance, molybdenum elements are valued for their durability and how they perform in the day-to-day realities of industrial production.

Durability Against Thermal Shock

Industrial furnaces are often subjected to rapid heating and cooling cycles. Molybdenum elements are engineered to withstand this thermal cycling without cracking or degrading.

This resilience translates directly into a longer service life and reduces the risk of unexpected element failure, which can cause costly production stoppages.

Long-Term Operational Longevity

The combination of oxidation resistance and thermal stability gives these elements a very long operational life. They do not suffer from the same aging effects as other materials that cause their resistance to drift over time.

This longevity reduces the total cost of ownership by minimizing replacement frequency and the associated labor and downtime costs.

Understanding the Trade-offs and Limitations

To make an informed decision, it is crucial to understand where molybdenum elements may not be the optimal choice. Their performance is highly dependent on the specific application and environment.

The Critical Role of Atmosphere

While MoSi2 elements excel in air, their maximum operating temperature must be lowered in low-oxygen, reducing, or nitrogen-rich atmospheres. The protective silica layer cannot form properly, making the element vulnerable to degradation.

Pure Molybdenum vs. MoSi2

It is important to distinguish between pure molybdenum and MoSi2. Pure molybdenum is used in vacuum or inert gas furnaces, often for moderate-temperature processes like hardening and brazing. It lacks the oxidation resistance of MoSi2 and would quickly burn out in air at high temperatures.

Brittleness at Room Temperature

Like many ceramic-based materials, MoSi2 elements are strong at high temperatures but can be brittle and fragile at room temperature. They require careful handling during furnace installation and maintenance to prevent breakage.

Making the Right Choice for Your Application

Selecting the correct heating element is a critical engineering decision. Your process requirements should be your primary guide.

- If your primary focus is extreme temperature processing in an air atmosphere (up to 1800°C): Molybdenum disilicide (MoSi2) is the definitive choice due to its protective oxide layer and stability.

- If your primary focus is process consistency and repeatable heating profiles: The stable resistance and non-aging characteristics of MoSi2 ensure unparalleled thermal control over the long term.

- If you are operating a vacuum or inert gas furnace: Pure molybdenum elements are a reliable and cost-effective solution, particularly for moderate-temperature applications.

By understanding these distinct capabilities and limitations, you can leverage molybdenum's properties to achieve superior control and efficiency in your most demanding thermal processes.

Summary Table:

| Key Benefit | Description | Max Operating Temp |

|---|---|---|

| Extreme Temperature Stability | Reliable performance in furnace temperatures up to 1800°C (3272°F). | 1800°C (up to 1900°C) |

| Superior Oxidation Resistance | Forms a self-healing silica layer in air, preventing rapid degradation. | Optimal in Air Atmosphere |

| Long Operational Longevity | Stable electrical resistance ensures consistent, repeatable heating profiles. | Long Service Life |

| Durability Against Thermal Shock | Withstands rapid heating/cooling cycles common in industrial production. | High Thermal Cycling Resistance |

Ready to Enhance Your High-Temperature Processes?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact our experts today to discuss how our robust molybdenum heating elements can deliver the precise, reliable thermal control your critical applications demand.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing