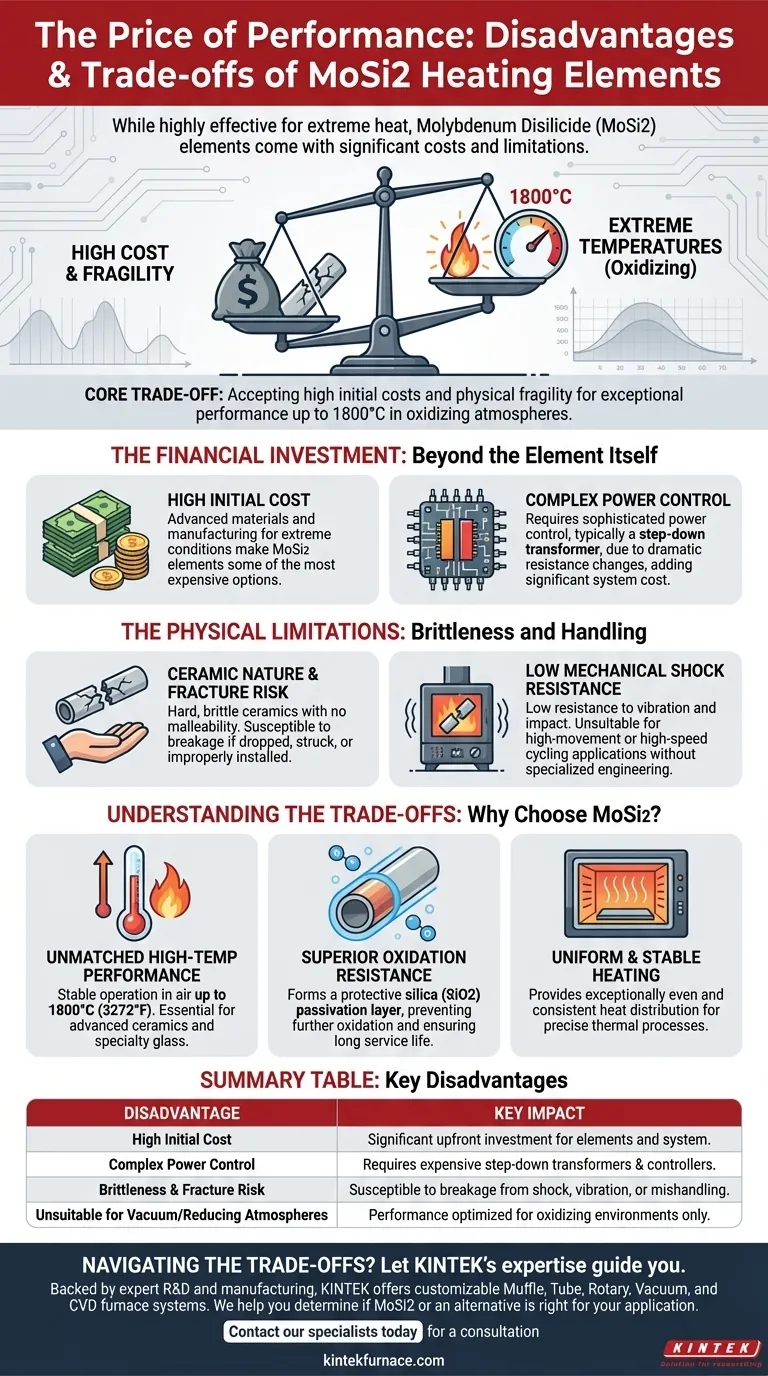

While highly effective, Molybdenum Disilicide (MoSi2) heating elements are not a universal solution. Their primary disadvantages are their significant upfront cost, the need for expensive power control systems, and their inherent brittleness, which makes them susceptible to fracture from mechanical shock.

The core trade-off with MoSi2 elements is accepting high initial costs and physical fragility in exchange for exceptional performance at extreme temperatures (up to 1800°C) within oxidizing atmospheres.

The Financial Investment: Beyond the Element Itself

Choosing MoSi2 elements involves more than just the price of the component. The total cost of ownership is significantly influenced by the complex electrical systems required to operate them safely and efficiently.

High Initial Cost

MoSi2 elements are among the most expensive heating element options available. This cost reflects the advanced materials and manufacturing processes required to produce components that can withstand such extreme operating conditions.

Complex Power Control Requirements

Unlike simple metallic elements, MoSi2 cannot be connected directly to a standard power line. Their electrical resistance changes dramatically with temperature, necessitating sophisticated power control.

This typically requires a step-down transformer to manage their low voltage and high startup current, adding significant cost and complexity to the overall furnace design.

The Physical Limitations: Brittleness and Handling

The very properties that allow MoSi2 to perform at high temperatures also define its physical weaknesses. These elements are not ductile metals; they are hard, brittle ceramics.

Ceramic Nature and Fracture Risk

MoSi2 elements are susceptible to fracture if not handled carefully. They lack the malleability of metallic elements and can break if dropped, struck, or improperly installed.

Low Mechanical Shock Resistance

This brittleness translates to a low resistance to mechanical shock or vibration. Applications involving significant movement, high-speed cycling, or potential impacts are generally unsuitable for MoSi2 elements without specialized furnace engineering.

Understanding the Trade-offs: Why Choose MoSi2?

Despite these clear disadvantages, MoSi2 elements are indispensable in certain industries. Their drawbacks are often considered necessary trade-offs for achieving performance that other materials cannot match.

Unmatched High-Temperature Performance

MoSi2 elements are engineered for the most demanding thermal processes, capable of stable operation in air at temperatures up to 1800°C (3272°F). This makes them essential for producing advanced ceramics, melting specialty glass, and other high-heat applications.

Superior Oxidation Resistance

The defining advantage of MoSi2 is its ability to form a protective silica (SiO2) passivation layer on its surface when heated in an oxidizing atmosphere. This thin, glass-like coating prevents further oxidation and ensures a long service life at temperatures that would destroy most other materials.

Uniform and Stable Heating

When operated correctly, these elements provide exceptionally even and consistent heat distribution. This uniformity is critical in processes where precise temperature control is necessary to prevent product defects or ensure material integrity.

Making the Right Choice for Your Application

Your decision should be based on a clear understanding of your process requirements versus the inherent limitations of the material.

- If your primary focus is achieving the highest possible temperatures in an air or oxidizing atmosphere: The performance of MoSi2 is often the only viable option, and you must budget for the associated costs and careful handling.

- If your primary focus is cost-effectiveness for mid-range temperatures: Simpler, more robust metallic elements are likely a more practical and economical choice.

- If your primary focus is operation in a vacuum or a furnace with high vibration: The brittleness of MoSi2 makes it a high-risk material, and alternatives like pure Molybdenum or Tungsten elements should be considered.

Ultimately, selecting MoSi2 is a strategic decision to prioritize extreme temperature capability over cost and mechanical durability.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Initial Cost | Significant upfront investment for the elements and system. |

| Complex Power Control | Requires expensive step-down transformers and controllers. |

| Brittleness & Fracture Risk | Susceptible to breakage from shock, vibration, or mishandling. |

| Unsuitable for Vacuum/Reducing Atmospheres | Performance is optimized for oxidizing environments only. |

Navigating the trade-offs of high-temperature heating elements is complex. Let KINTEK's expertise guide you.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique needs. We can help you determine if MoSi2 is the right choice for your extreme-temperature application or recommend a more suitable alternative.

Contact our specialists today for a consultation to optimize your lab's thermal processing efficiency and reliability.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance