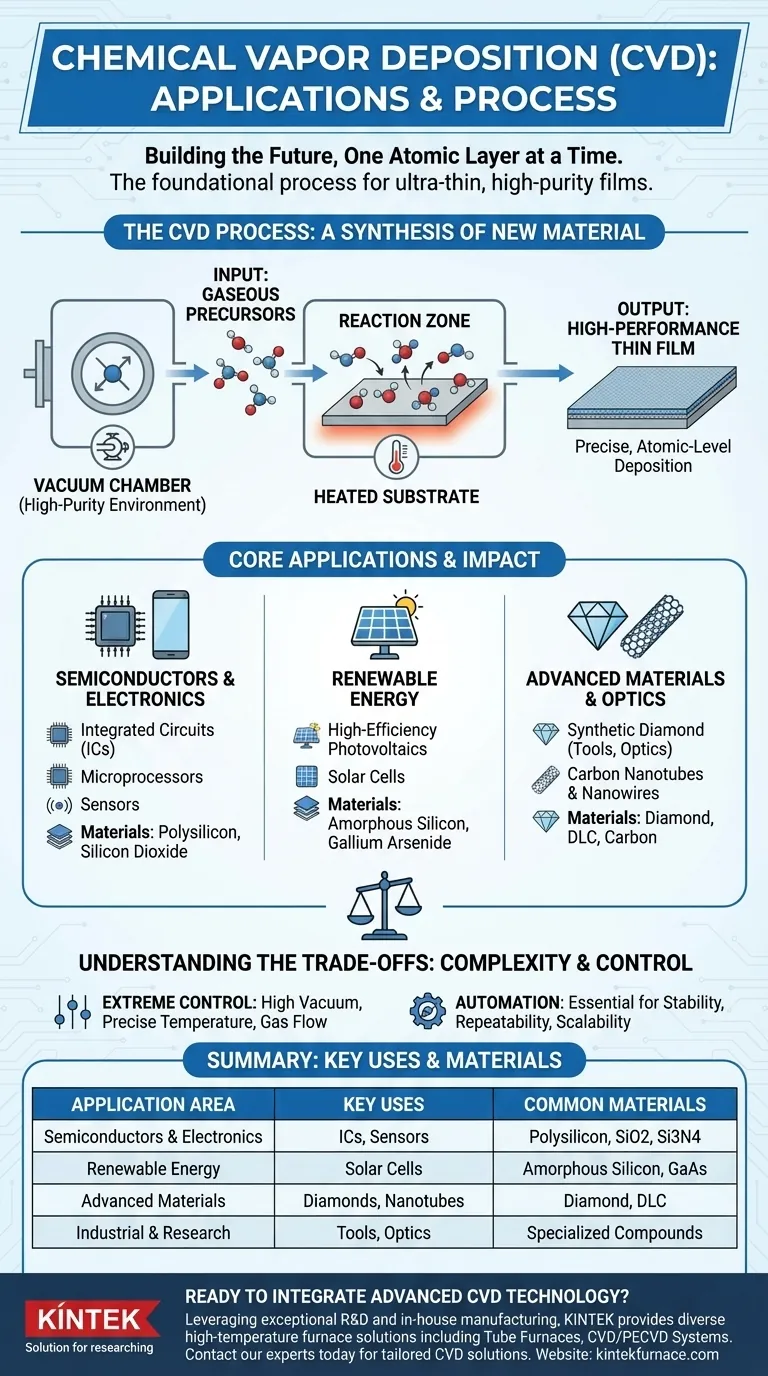

In essence, chemical vapor deposition (CVD) is the foundational process used to build the ultra-thin, high-purity films that power our most advanced technologies. Its applications range from the microprocessors in your smartphone and the sensors in your car to the creation of synthetic diamonds and next-generation photovoltaic cells.

The core value of CVD is its ability to deposit material one atomic layer at a time. This precise control allows for the creation of exceptionally pure, high-performance thin films, which are the essential building blocks for the semiconductor, electronics, and advanced materials industries.

How CVD Enables Modern Technology

Chemical vapor deposition is a method performed under a highly controlled vacuum, far below atmospheric pressure. The process is not simply a "coating" in the traditional sense; it is a synthesis of new material directly on a surface.

The Deposition Process

A substrate, which is the base material to be coated, is placed inside the vacuum chamber. Gaseous molecules, known as precursors, are then introduced into the chamber.

These precursors react or decompose upon contact with the heated substrate. The chemical reaction leaves behind a solid material, forming a thin, durable film on the substrate's surface, one layer of atoms or molecules at a time.

Achieving Purity and Performance

Because this process occurs in a high-vacuum environment, contamination from the atmosphere is minimized. This results in thin films of extremely high quality and purity, which is critical for applications like microelectronics where even the smallest impurity can cause a device to fail.

Core Application: The Semiconductor Industry

The most widespread and critical use of CVD is in the manufacturing of semiconductor devices. It is a fundamental step in producing virtually all modern integrated circuits (ICs).

Building Integrated Circuits (ICs)

CVD is used to deposit various materials that form the intricate, layered structures of a microchip. This includes depositing layers of polysilicon, silicon dioxide, and other compounds that act as conductors, insulators, and gates for transistors.

Powering Photovoltaics

The technology is also vital for creating solar cells. CVD is used to deposit films of amorphous polysilicon or other materials like gallium arsenide, which are essential for converting sunlight into electricity efficiently.

Expanding into Advanced Materials and Optics

Beyond conventional semiconductors, specialized CVD techniques enable the creation of materials with unique properties that would be difficult or impossible to produce otherwise.

Synthetic Diamond and Carbon Nanostructures

Microwave plasma CVD systems are specifically designed to "grow" films of polycrystalline or monocrystalline diamond. These synthetic diamond films have applications in industrial cutting tools, optics, and advanced electronics due to their extreme hardness and thermal conductivity.

This same process can be adapted to produce carbon nanotubes and nanowires, materials with extraordinary strength and electrical properties used in research, electronics, and medicine.

A Broad Industrial Footprint

These advanced materials find uses across a surprising range of sectors, including optics, microwave technology, micromechanics, material processing, and even electrochemistry.

Understanding the Trade-offs: The Complexity of CVD

The precision of CVD comes at a cost of complexity. The process requires a significant investment in equipment and strict operational control to achieve the desired results.

The Need for Extreme Control

CVD systems must maintain a high vacuum with very low leakage to prevent contamination. The process is highly sensitive to variables like pressure, gas flow rates, and especially temperature, which often must be measured with high-precision pyrometers at ranges exceeding 2000°C.

Automation is Key

Due to the number of critical variables, modern CVD systems are fully automated. This ensures the stability of the plasma and the precise, repeatable deposition of films, but it also highlights the technical sophistication required to operate and maintain the equipment.

Making the Right Choice for Your Industry

The specific application of CVD depends entirely on the desired outcome, from mass-produced consumer goods to highly specialized research materials.

- If your primary focus is consumer and automotive electronics: CVD is the non-negotiable process for manufacturing the core ICs, sensors, and microprocessors that power smartphones, wearables, and vehicle control systems.

- If your primary focus is renewable energy: CVD is essential for producing the high-efficiency photovoltaic films used in modern solar panels.

- If your primary focus is research and advanced materials: Specialized CVD techniques are the key to developing next-generation materials like synthetic diamonds, carbon nanotubes, and specialized optical coatings.

Ultimately, chemical vapor deposition is less a single application and more a fundamental enabling technology that makes much of our modern world possible.

Summary Table:

| Application Area | Key CVD Uses | Common Materials Deposited |

|---|---|---|

| Semiconductors & Electronics | Manufacturing integrated circuits (ICs), microprocessors, sensors | Polysilicon, Silicon Dioxide, Silicon Nitride |

| Renewable Energy | Production of high-efficiency solar cells (photovoltaics) | Amorphous Silicon, Gallium Arsenide |

| Advanced Materials | Creating synthetic diamonds, carbon nanotubes, optical coatings | Diamond, Carbon Nanotubes, DLC |

| Industrial & Research | Cutting tools, optics, micromechanics, electrochemistry | Various specialized compounds |

Ready to integrate advanced CVD technology into your R&D or production line?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, CVD/PECVD Systems, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements for thin-film deposition.

Contact our experts today to discuss how our tailored CVD solutions can accelerate your project's success.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication