Spark Plasma Sintering (SPS) fundamentally outperforms traditional methods for Mo-Cr-Y composites by utilizing pulsed electric current and simultaneous pressure to achieve rapid densification.

Unlike conventional sintering, which relies on external heating elements, SPS generates a plasma discharge between powder particles. This mechanism allows for extremely high heating rates—up to 100 °C/min—and significantly shorter sintering durations. The result is a composite with superior mechanical properties, driven by a refined microstructure that traditional methods cannot easily replicate.

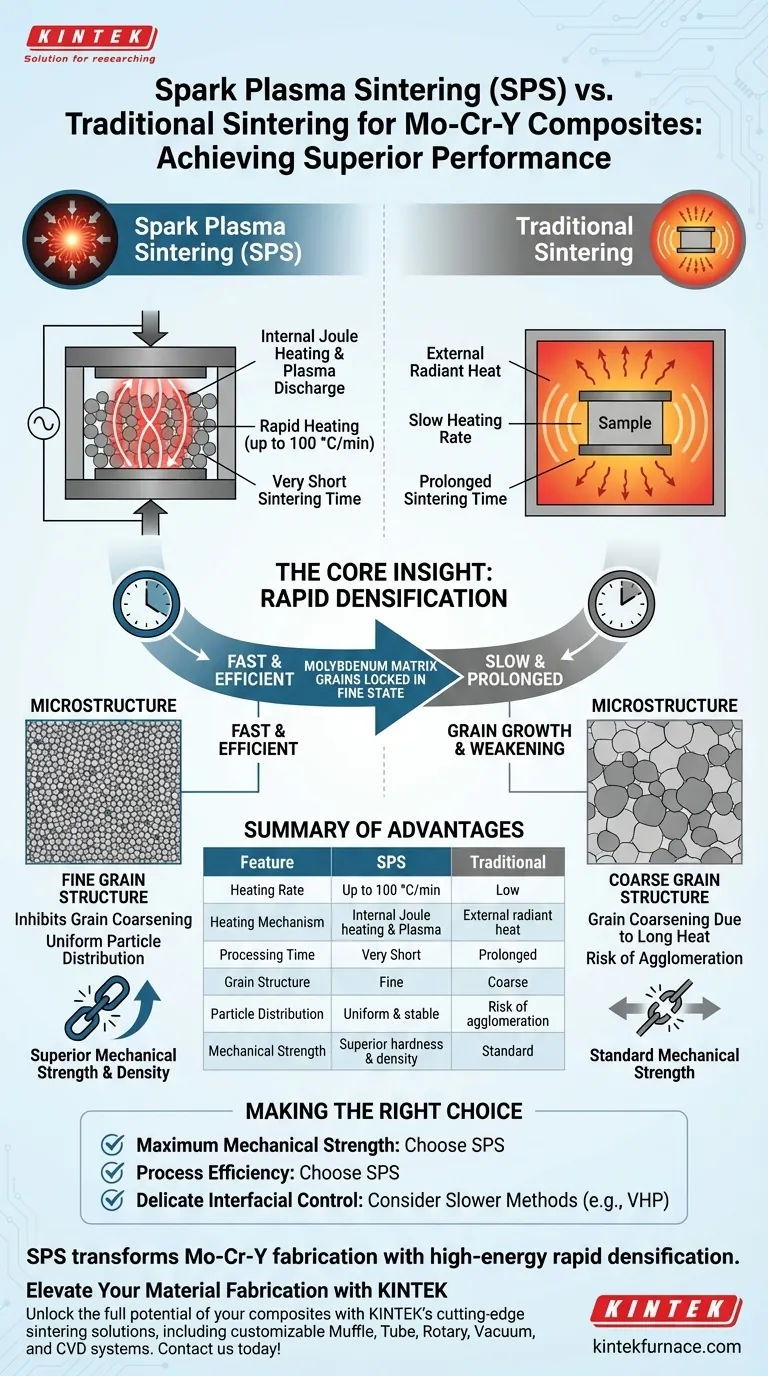

The Core Insight Traditional sintering often requires long exposure to high heat, which causes grains to grow and weakens the material. SPS solves this by densifying the material so quickly that the molybdenum matrix grains are locked in a fine state, preventing coarsening while ensuring the strengthening particles are evenly distributed.

The Mechanics of Rapid Densification

Internal Heating via Pulsed Current

Traditional furnaces heat a sample from the outside in. SPS, however, uses pulsed current to generate heat directly within the powder compact and the mold (Joule heating).

This internal heat generation creates significantly higher temperatures at the contact points between particles compared to the bulk sample temperature. This allows the material to densify efficiently without overheating the entire structure.

Plasma Discharge and Pressure

In the context of Mo-Cr-Y composites, the process utilizes uniaxial pressure combined with the pulsed current.

This combination triggers a plasma discharge between the powder particles. This discharge cleans particle surfaces and activates sintering at a much faster rate than radiant heat, facilitating the rapid heating rate of 100 °C/min.

Microstructural Advantages

Inhibiting Grain Coarsening

The most critical advantage of SPS for Mo-Cr-Y composites is the preservation of the microstructure.

In traditional sintering, long holding times at high temperatures allow grains to merge and grow large (coarsening). Because SPS achieves full densification in a very short time, it effectively inhibits the coarsening of the molybdenum matrix grains. A finer grain structure directly correlates to higher hardness and strength.

Efficient Particle Distribution

SPS ensures the efficient distribution of second-phase dispersion particles throughout the matrix.

Rapid consolidation prevents these particles from agglomerating or segregating. This uniform dispersion is essential for the "composite" aspect of the material to function correctly, enhancing the overall mechanical performance.

Understanding the Trade-offs

Speed vs. Diffusion Control

While the speed of SPS is generally an advantage, it can be a limitation for specific material goals.

Supplementary data regarding other composite systems (such as SiC/Al) suggests that the rapid heating of SPS creates a non-equilibrium state. In contrast, methods like Vacuum Hot Pressing (VHP) offer gentler heating rates.

If a material system requires uniform solid-state diffusion or delicate control over interfacial reactions to prevent excessive reaction products, the aggressive nature of SPS might be less suitable than the slower, more controlled environment of VHP.

Making the Right Choice for Your Goal

To determine if SPS is the right processing route for your specific composite application, consider your primary performance metrics:

- If your primary focus is Maximum Mechanical Strength: SPS is superior because it inhibits grain growth and creates a fine, dense microstructure that boosts hardness and toughness.

- If your primary focus is Process Efficiency: SPS is the clear choice due to its ability to achieve densification with heating rates of 100 °C/min and very short holding times.

- If your primary focus is Delicate Interfacial Control: You may want to evaluate if the rapid kinetics of SPS allow for the precise diffusion bonding you require, or if a slower method like VHP is necessary.

SPS transforms the fabrication of Mo-Cr-Y composites by replacing prolonged heat exposure with high-energy rapid densification, resulting in a stronger, more uniform material.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Sintering Methods |

|---|---|---|

| Heating Rate | Up to 100 °C/min (Rapid) | Low (Slow external heating) |

| Grain Structure | Fine (Inhibits grain coarsening) | Coarse (Due to long heat exposure) |

| Heating Mechanism | Internal Joule heating & Plasma | External radiant heat |

| Processing Time | Very Short | Prolonged |

| Mechanical Strength | Superior hardness and density | Standard |

| Particle Distribution | Uniform & stable | Risk of agglomeration |

Elevate Your Material Fabrication with KINTEK

Unlock the full potential of your Mo-Cr-Y composites and advanced materials with KINTEK’s cutting-edge sintering solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside lab high-temperature furnaces, all fully customizable to meet your unique research and production needs.

Whether you require the rapid kinetics of SPS or the precise control of vacuum systems, our engineers are ready to help you optimize your microstructure and mechanical performance. Contact us today to find the perfect solution for your lab!

Visual Guide

References

- Haochen Guan, Zhangjian Zhou. The Effect of Cr Addition on the Strength and High Temperature Oxidation Resistance of Y2O3 Dispersion Strengthened Mo Composites. DOI: 10.3390/ma17112550

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a Vacuum Hot Pressing (VHP) furnace facilitate the preparation of highly dense Mg3Sb2? Expert Densification

- What are the technical advantages of using Pulsed Current Sintering (PCS) for Ag2S1-xTex? Optimize Your Microstructure

- What is the process of vacuum laminating? Create Strong, Lightweight Composite Parts

- What function does Spark Plasma Sintering (SPS) equipment serve in recycling aluminum alloy scrap? High-Value Recovery

- How does the porosity of materials differ between hot pressing and cold compacting and sintering? Compare Methods for Optimal Density

- What types of shapes can be manufactured using vacuum hot pressing? From Simple Blocks to Complex Components

- What are the advantages of using a VHP furnace over CVD for ZnS? Boost Strength and Efficiency with Vacuum Hot Pressing

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification