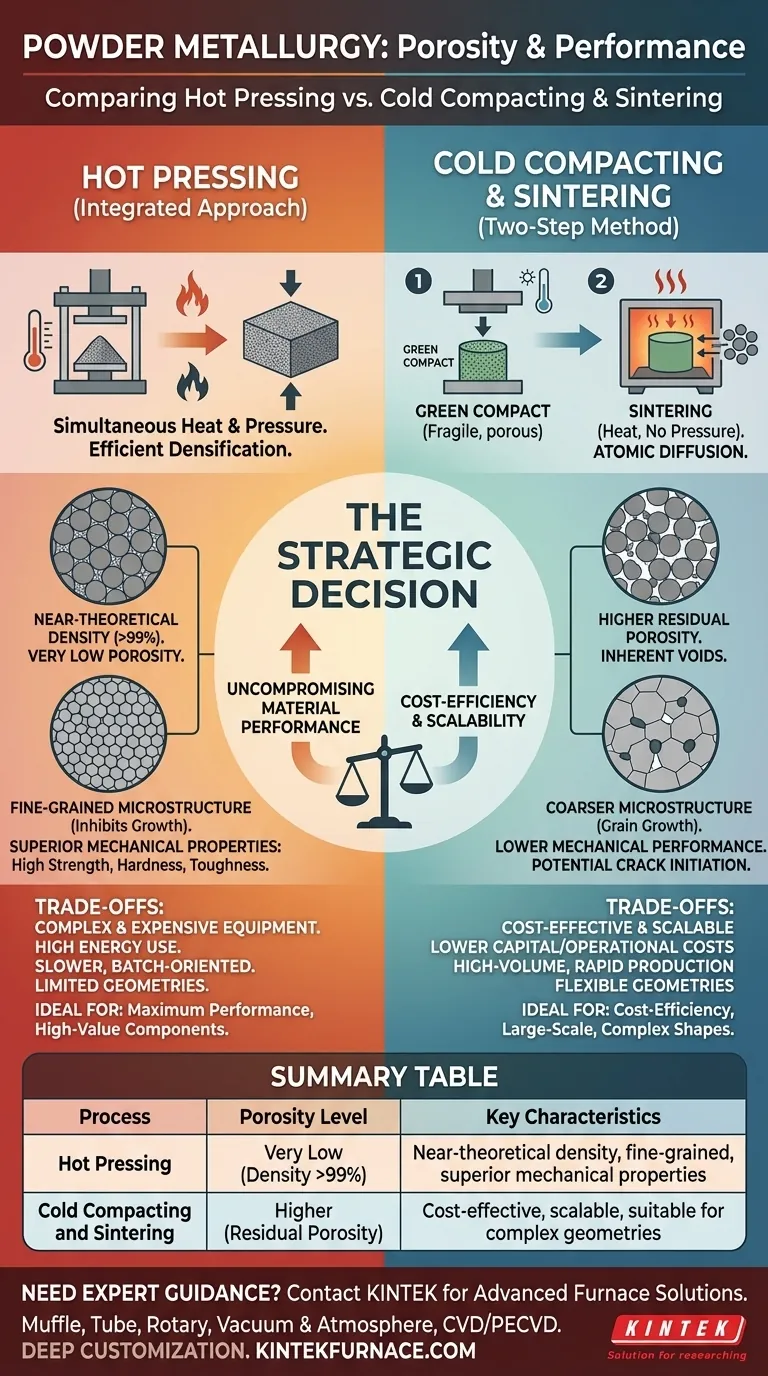

In powder metallurgy, the defining difference between these two methods lies in the final density of the material. Hot pressing consistently produces parts with significantly lower porosity, achieving densities that are near-theoretically perfect. In contrast, the conventional two-step process of cold compacting and sintering almost always results in a component with a higher, and often less uniform, level of residual porosity.

The choice is not merely technical; it is a strategic decision. You must balance the uncompromising material performance achieved through hot pressing against the cost-efficiency and scalability offered by cold compacting and sintering.

The Fundamental Process Difference

To understand why porosity differs, you must first understand how each process works. The sequence and combination of heat and pressure are the critical factors.

Cold Compacting and Sintering: The Two-Step Method

This is a sequential process. First, metal powder is pressed into a desired shape at room temperature using a die. This initial part, known as a "green compact," is fragile and contains significant porosity.

In the second step, this compact is heated in a furnace to a temperature below its melting point. This sintering process allows the powder particles to bond and fuse, which reduces porosity and increases strength. However, without external pressure, it is difficult to eliminate all voids.

Hot Pressing: The Integrated Approach

Hot pressing, or hot isostatic pressing (HIP), is a single-step, integrated process. Heat and high pressure are applied simultaneously to the powder.

By heating the material while it is being compressed, the particles become more plastic and malleable. This allows the external pressure to be far more effective at forcing the particles together, collapsing the voids between them and driving out trapped gases.

How Each Process Dictates Porosity and Microstructure

The final properties of a component are a direct result of its internal structure. Both porosity and grain size are determined by the manufacturing path.

Achieving Near-Theoretical Density with Hot Pressing

The simultaneous application of heat and pressure in hot pressing is exceptionally efficient at densification. This process can achieve final densities greater than 99% of the theoretical maximum.

This near-total elimination of porosity directly translates to superior mechanical properties, including higher strength, hardness, and fracture toughness.

Inherent Porosity in Cold Compacting

During cold compacting and sintering, densification relies solely on atomic diffusion during the heating phase. While this shrinks the part and reduces pore volume, some pores inevitably remain isolated and trapped within the material.

The resulting porosity negatively impacts mechanical performance, acting as stress concentration points where cracks can initiate.

The Critical Role of Grain Size

Hot pressing typically uses lower temperatures and shorter cycle times. This, combined with intense pressure, inhibits grain growth, resulting in a very fine-grained microstructure. Fine grains further enhance a material's strength and durability.

Conversely, to achieve adequate density, conventional sintering often requires higher temperatures or longer hold times. This environment promotes grain growth, leading to a coarser microstructure that can reduce the material's overall mechanical performance.

Understanding the Trade-offs: Performance vs. Practicality

Choosing a process is rarely about performance alone. You must weigh the superior material properties fatores against significant differences in manufacturing cost, speed, and complexity.

Cost and Complexity

Hot pressing equipment is complex and must withstand extreme temperatures and pressures, making it significantly more expensive to purchase and operate. The process also consumes more energy.

Cold compacting and sintering rely on simpler, more established technologies, resulting in lower capital investment and operational costs.

Production Speed and Scale

Cold compacting is a rapid process, and sintering can be done in large batches, making it ideal for high-volume, large-scale production.

Hot pressing is a slower, batch-oriented process. Completing a full densification cycle can take 3-10 minutes, compared to the hours often required for sintering, but the process itself is not suited for mass production. It is better for smaller runs of high-value components.

Material and Geometric Limitations

The dies used in hot pressing must be made from materials that can endure high temperatures, which can limit options and increase tooling costs. The shapes that can be produced are often simpler.

Cold compacting offers greater flexibility in creating complex geometries.

Making the Right Choice for Your Application

Your final decision must be guided by the non-negotiable requirements of your project.

- If your primary focus is maximum performance and density: Choose hot pressing for its unique ability to create near-fully dense, fine-grained materials with superior mechanical strength.

- If your primary focus is cost-effective, large-scale production: Opt for cold compacting and sintering, as it is a far more economical and scalable process for applications where some residual porosity is acceptable.

- If your primary focus is creating complex geometries at a low cost: Cold compacting provides more design freedom, but you must engineer around the trade-off in mechanical properties.

Ultimately, understanding this relationship between process, porosity, and performance empowers you to select the manufacturing path that aligns perfectly with your engineering and business goals.

Summary Table:

| Process | Porosity Level | Key Characteristics |

|---|---|---|

| Hot Pressing | Very Low (Density >99%) | Near-theoretical density, fine-grained microstructure, superior mechanical properties |

| Cold Compacting and Sintering | Higher (Residual Porosity) | Cost-effective, scalable, suitable for complex geometries |

Need expert guidance on selecting the right high-temperature furnace for your powder metallurgy process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether for hot pressing or sintering applications. Contact us today to enhance your lab's efficiency and achieve optimal material performance!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials