Vacuum drying provides a critical protective environment for processing temperature-sensitive composites like PB2T-TEG-TiO2-X. By lowering the system pressure, you allow solvents such as ethanol and chloroform to evaporate rapidly at significantly reduced temperatures (approximately 40 °C), directly avoiding the thermal stress associated with conventional ovens.

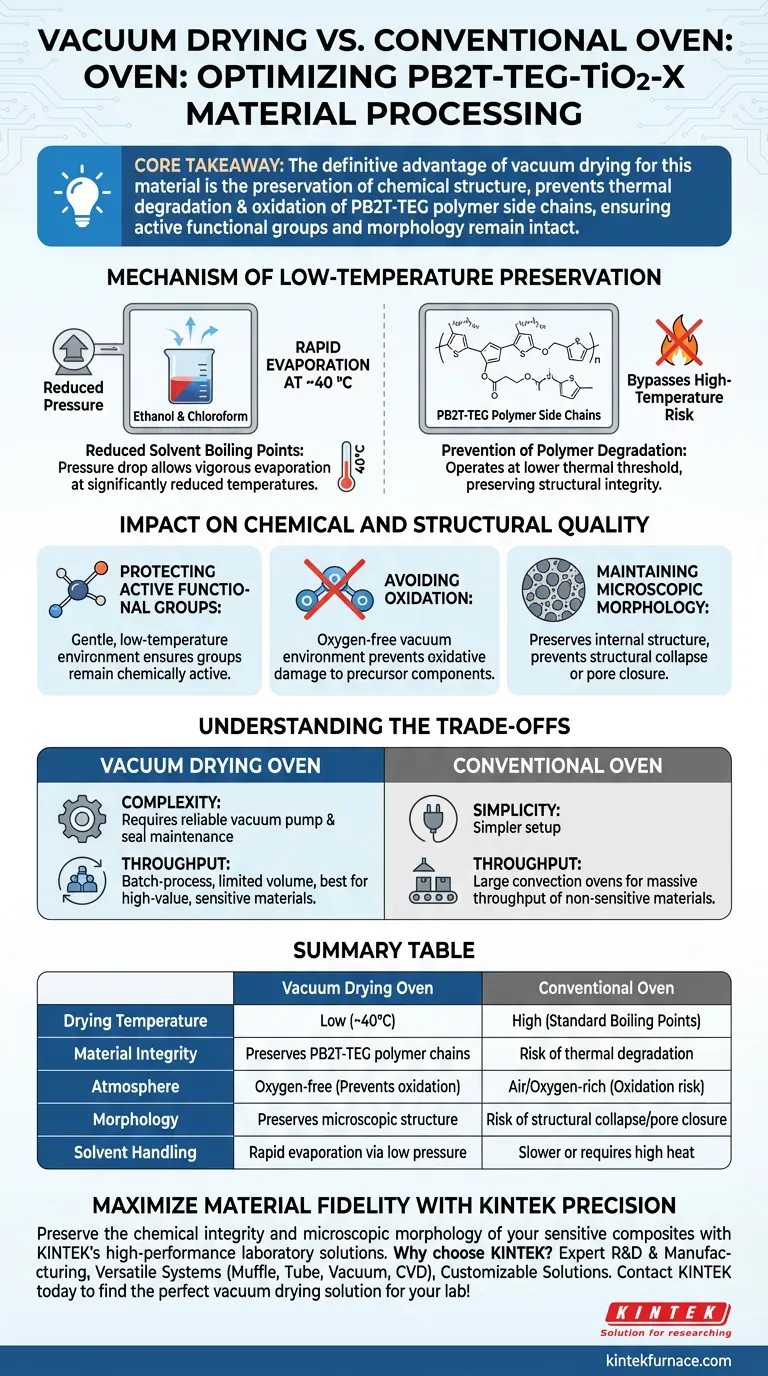

Core Takeaway The definitive advantage of vacuum drying for this specific material is the preservation of chemical structure. It prevents the thermal degradation and oxidation of PB2T-TEG polymer side chains, ensuring that active functional groups and the material's microscopic morphology remain intact.

Mechanism of Low-Temperature Preservation

Reduced Solvent Boiling Points

The primary mechanism at work is the relationship between pressure and vaporization. By reducing the pressure within the chamber, the boiling points of solvents like ethanol and chloroform drop significantly.

This allows these solvents to evaporate vigorously at temperatures as low as 40 °C. In a conventional oven, achieving similar evaporation rates would require temperatures that could compromise the material.

Prevention of Polymer Degradation

PB2T-TEG-TiO2-X composites contain sensitive polymer components. High temperatures in standard ovens risk thermal degradation of the PB2T-TEG polymer side chains.

Vacuum drying bypasses this risk entirely. By operating at a lower thermal threshold, you preserve the structural integrity of the polymer matrix.

Impact on Chemical and Structural Quality

Protecting Active Functional Groups

The functionality of your material depends on its chemical composition. High heat can sever or alter the active functional groups within the composite.

The gentle, low-temperature environment of the vacuum oven ensures these groups remain chemically active and available for their intended reaction or application.

Avoiding Oxidation

Standard ovens operate in an air environment, which introduces oxygen at high temperatures—a recipe for rapid oxidation.

A vacuum oven evacuates oxygen from the chamber. This creates an inert environment that prevents oxidative damage, which is critical for maintaining the stability of the precursor components.

Maintaining Microscopic Morphology

The physical structure of the composite is just as important as its chemistry. Rapid, high-heat drying can cause structural collapse or pore closure.

Vacuum drying preserves the microscopic morphology of the composite. This ensures that the internal structure remains open and consistent, rather than densifying or distorting due to thermal stress.

Understanding the Trade-offs

Equipment Complexity vs. Simplicity

While superior for quality, a vacuum drying setup is more complex than a conventional oven. It requires a reliable vacuum pump and strict maintenance of seals to ensure pressure remains consistent.

Throughput Limitations

Vacuum ovens are generally batch-process devices with limited internal volume compared to large convection ovens.

If your goal is massive throughput of non-sensitive materials, a vacuum oven may be a bottleneck. However, for high-value, sensitive materials like PB2T-TEG-TiO2-X, this trade-off is necessary to prevent batch failure.

Making the Right Choice for Your Goal

To determine if you should strictly adhere to vacuum drying for your specific batch, consider your primary constraints:

- If your primary focus is Material Fidelity: Use the vacuum oven at ~40 °C to strictly protect polymer side chains and prevent oxidation.

- If your primary focus is Solvent Removal Speed: Use the vacuum oven to lower the boiling point of ethanol/chloroform, accelerating drying without adding destructive heat.

By controlling pressure, you control the quality of the final composite, ensuring the PB2T-TEG-TiO2-X retains the precise properties required for its application.

Summary Table:

| Feature | Vacuum Drying Oven | Conventional Oven |

|---|---|---|

| Drying Temperature | Low (~40°C) | High (Standard Boiling Points) |

| Material Integrity | Preserves PB2T-TEG polymer chains | Risk of thermal degradation |

| Atmosphere | Oxygen-free (Prevents oxidation) | Air/Oxygen-rich (Oxidation risk) |

| Morphology | Preserves microscopic structure | Risk of structural collapse/pore closure |

| Solvent Handling | Rapid evaporation via low pressure | Slower or requires high heat |

Maximize Material Fidelity with KINTEK Precision

Preserve the chemical integrity and microscopic morphology of your sensitive composites with KINTEK’s high-performance laboratory solutions. Whether you are working with complex PB2T-TEG-TiO2-X matrices or other heat-sensitive materials, our advanced equipment ensures reproducible results without the risk of oxidation or thermal stress.

Why choose KINTEK?

- Expert R&D & Manufacturing: Decades of experience in high-temperature and vacuum technologies.

- Versatile Systems: From Muffle and Tube furnaces to specialized Vacuum and CVD systems.

- Customizable Solutions: Lab high-temp furnaces tailored to your unique research or production needs.

Contact KINTEK today to find the perfect vacuum drying solution for your lab!

Visual Guide

References

- Bingke Zhang, Ergang Wang. Facile Synthesis of Organic–Inorganic Hybrid Heterojunctions of Glycolated Conjugated Polymer‐TiO<sub>2−X</sub> for Efficient Photocatalytic Hydrogen Evolution. DOI: 10.1002/smll.202402649

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Induction Melting Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the safety considerations when using nitrogen and argon in vacuum furnaces? Prevent Asphyxiation Risks in Your Lab

- What are the core process conditions provided by a resistance furnace in the vacuum purification of high-purity magnesium? Master Thermal Control for Purity

- Why is vertical stack loading superior to staggered stack loading in batch gas quenching? Optimize Gas Flow & Quality

- What materials are used in vacuum brazing? Join Reactive & Dissimilar Metals for High-Integrity Assemblies

- Why are high vacuum pump sets critical for Liquid Metal Extraction? Ensure Metal Purity and Process Efficiency

- Why is a vacuum oven required for drying ZIF67/NiMoO4 composite materials? Protect Delicate Material Architecture

- What are the advantages of a dual-vacuum furnace for magnesium purification? Maximize Purity & Equipment Lifespan

- What are the selection criteria for vacuum pumps in vacuum furnaces? Optimize for Purity and Efficiency