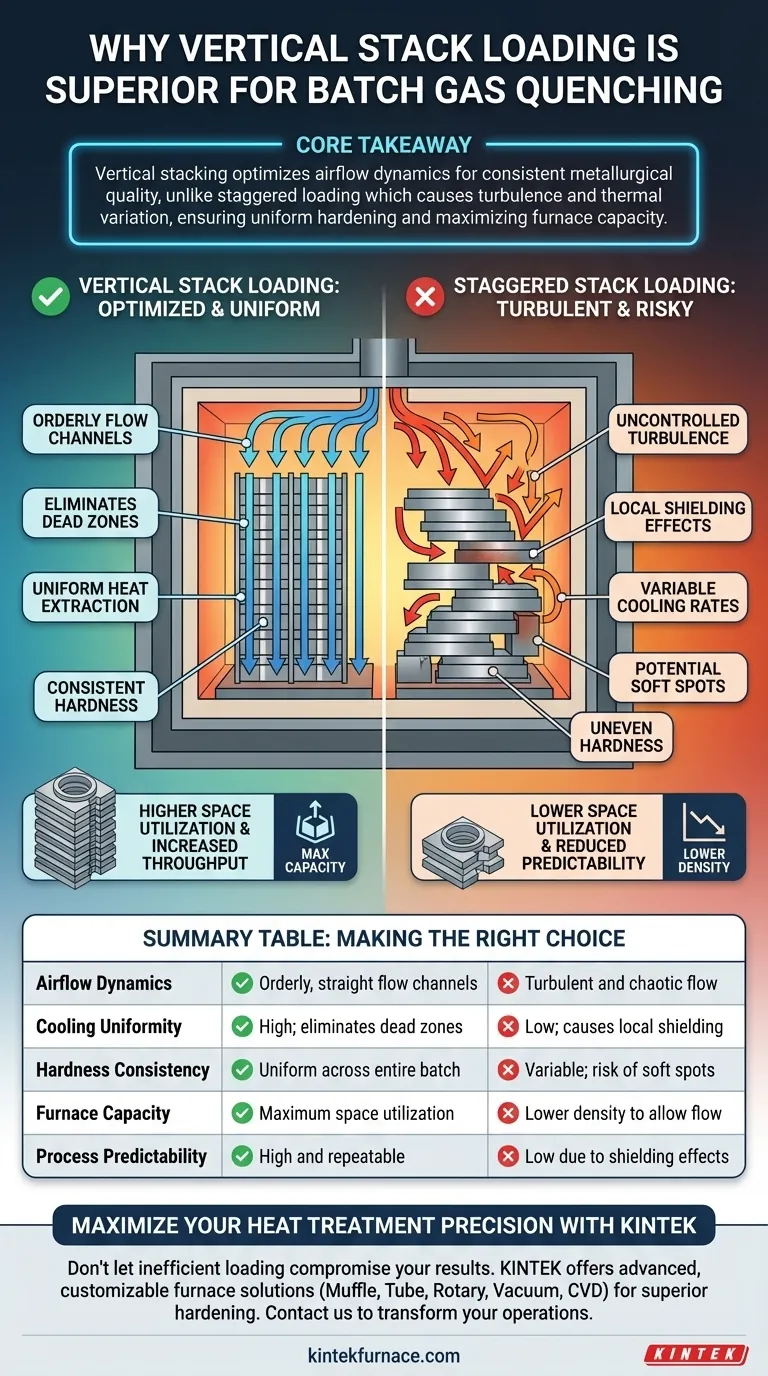

Vertical stack loading is the superior choice for batch gas quenching because it optimizes airflow dynamics to ensure consistent metallurgical quality. Unlike staggered arrangements, which disrupt gas velocity and create thermal variation, vertical stacking aligns workpieces to allow an orderly, unobstructed flow of cooling medium while simultaneously maximizing furnace capacity.

Core Takeaway: Staggered loading introduces turbulence and "shielding" effects that lead to uneven cooling and potential soft spots. Vertical stacking solves this by creating clear flow channels for the gas, ensuring uniform hardening across the entire batch while increasing the total number of parts processed per cycle.

Achieving Metallurgical Consistency

Optimizing the Flow Field

To achieve uniform hardness, the quenching gas must extract heat at the same rate from every part. Vertical stack loading facilitates this by creating straight, vertical channels between workpieces.

This configuration allows the gas to move in an orderly fashion, maintaining high velocity from the top to the bottom of the load.

Eliminating Low-Speed Zones

A critical flaw in non-optimized loading is the creation of "dead zones" where gas velocity drops. The primary reference indicates that vertical configurations effectively eliminate low-speed zones, particularly near the outer walls of the furnace.

By maintaining consistent gas speed throughout the chamber, you prevent the formation of soft spots on parts located at the periphery of the load.

The Risks of Staggered Loading

The Problem of Local Shielding

Staggered stacking creates a physical barrier to the cooling medium. Parts positioned upstream effectively shield those behind or below them, preventing fresh, cold gas from reaching the surfaces of downstream parts.

This results in significant variations in cooling rates, meaning parts from the same batch may have different metallurgical properties.

Turbulence and Unpredictability

While some turbulence is inevitable in high-pressure quenching, staggered loading generates uncontrolled turbulence.

Instead of flowing smoothly over the surfaces, the gas is forced to change direction rapidly. This chaotic movement disrupts the heat transfer process, making it difficult to predict or control the final quality of the parts.

Production Efficiency and Capacity

Maximizing Space Utilization

Beyond quality, vertical stacking offers a distinct economic advantage. It provides higher space utilization, allowing you to fit a larger volume of parts into the furnace chamber without compromising airflow.

Increasing Throughput

Because the flow field is optimized, you can safely load the furnace to its maximum capacity. This results in larger furnace loading capacities per cycle, reducing the cost per part and increasing overall plant throughput.

Operational Considerations and Trade-offs

Fixturing Stability

While vertical stacking is superior for airflow, it requires robust fixturing. Parts must be secured so they do not touch or impede the vertical channels. Poorly stabilized vertical stacks can lead to parts shifting during the rapid pressure changes of quenching.

Geometry Dependence

Vertical loading is ideal for many geometries, but not all. Complex parts with deep recesses may still require specific orientation adjustments. You must ensure that the vertical orientation does not trap gas or liquid (if washing is involved) in internal cavities.

Making the Right Choice for Your Goal

To maximize the efficiency of your batch gas quenching production, align your loading pattern with your specific objectives:

- If your primary focus is Quality Consistency: Adopt vertical stacking to eliminate shielding and ensure every part experiences the same cooling rate.

- If your primary focus is Production Volume: Use vertical configurations to maximize the density of the load without risking the "dead zones" associated with staggered packing.

By matching your loading strategy to the physics of gas flow, you turn a variable process into a reliable, high-yield operation.

Summary Table:

| Feature | Vertical Stack Loading | Staggered Stack Loading |

|---|---|---|

| Airflow Dynamics | Orderly, straight flow channels | Turbulent and chaotic flow |

| Cooling Uniformity | High; eliminates dead zones | Low; causes local shielding |

| Hardness Consistency | Uniform across entire batch | Variable; risk of soft spots |

| Furnace Capacity | Maximum space utilization | Lower density to allow flow |

| Process Predictability | High and repeatable | Low due to shielding effects |

Maximize Your Heat Treatment Precision with KINTEK

Don't let inefficient loading patterns compromise your metallurgical results. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your unique production needs.

Ready to achieve superior hardening and increased throughput? Contact us today to discover how our advanced furnace technology can transform your batch quenching operations.

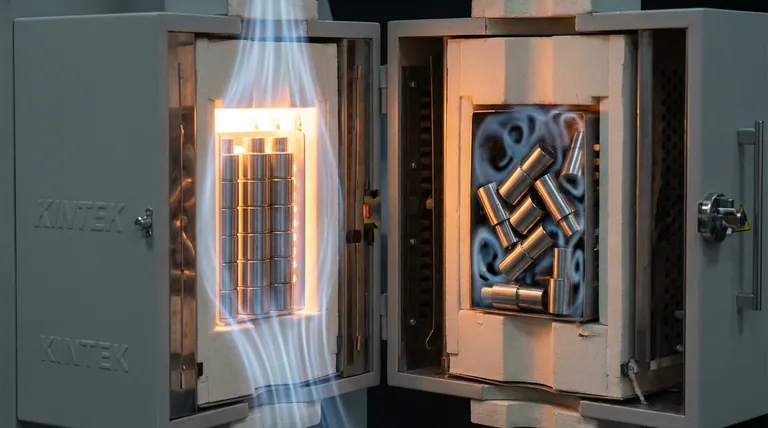

Visual Guide

References

- Zaiyong Ma, Jingbo Ma. Research on the uniformity of cooling of gear ring parts under vacuum high-pressure gas quenching. DOI: 10.1088/1742-6596/3080/1/012130

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the automotive industry applications of furnace brazing? Enhance Vehicle Performance with Strong, Leak-Proof Joints

- What are the primary applications of laboratory vacuum furnaces in scientific research? Unlock High-Purity Material Processing

- What industries benefit from High Vacuum Melting Furnaces? Unlock Purity for Aerospace, Biomedical & More

- What are common insulation materials used in vacuum furnaces? Optimize Heat Control for Your Lab

- How does an industrial vacuum heat treatment furnace facilitate the diffusion step in the OBD process? Expert Insights

- How does vacuum or protective atmosphere melting improve the quality of aerospace materials? Achieve Superior Purity and Performance

- What processes can vacuum carburizing furnaces perform? Unlock Versatile Heat Treatment Solutions

- What is the significance of a high-temperature vacuum sintering furnace? Achieving Ho:Y2O3 Optical Transparency