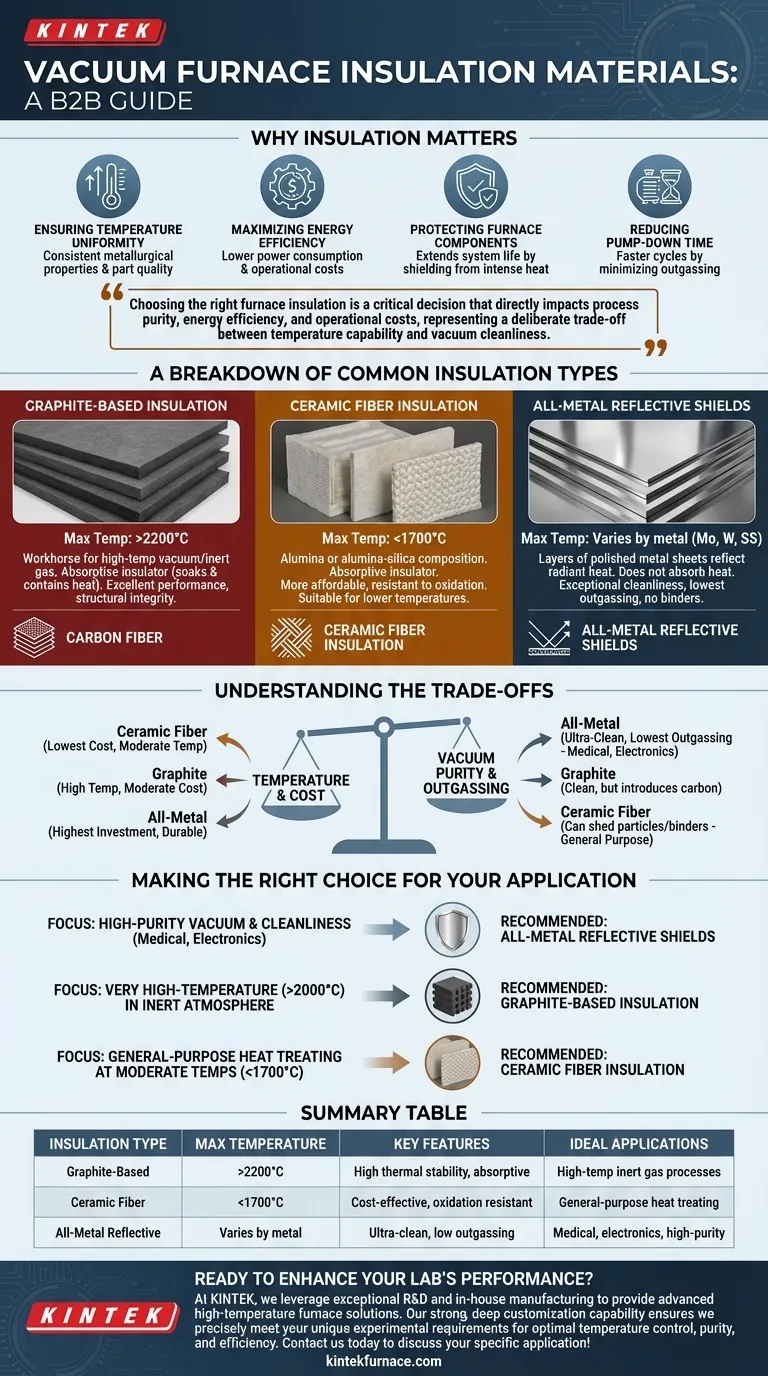

The most common insulation materials used in vacuum furnaces fall into three main categories: graphite-based insulation (like rigid felt or wafers), ceramic fiber panels, and all-metal reflective heat shields typically made from molybdenum, tungsten, or stainless steel. Each material is chosen based on the furnace's maximum operating temperature, the required vacuum purity, and the specific process being run.

Choosing the right furnace insulation is not merely about containing heat. It is a critical decision that directly impacts process purity, energy efficiency, and operational costs, with the ideal material representing a deliberate trade-off between temperature capability and vacuum cleanliness.

Why Insulation is Critical in a Vacuum Furnace

Proper insulation, often called a "hot zone," is the heart of an efficient and reliable vacuum furnace. Its performance dictates the quality of your results and the cost of operation.

Ensuring Temperature Uniformity

A well-designed insulation package ensures that heat is distributed evenly throughout the work area. This uniformity is critical for achieving consistent metallurgical properties and part quality.

Maximizing Energy Efficiency

Insulation's primary role is to prevent heat from escaping the hot zone. By reflecting or containing thermal energy, it drastically reduces the power required to reach and maintain a target temperature, lowering operational costs.

Protecting Furnace Components

The intense heat generated within the hot zone can damage the vacuum chamber, seals, and other external components. Insulation acts as a protective barrier, extending the life of the entire furnace system.

Reducing Pump-Down Time

Effective insulation helps minimize the outgassing of trapped molecules from the chamber walls by keeping them cooler. This allows the vacuum pumps to achieve the desired pressure level more quickly, shortening cycle times.

A Breakdown of Common Insulation Types

Each insulation material operates on different principles and offers a distinct set of advantages.

Graphite-Based Insulation

Graphite insulation, available as rigid boards or soft felt, is a workhorse for high-temperature vacuum and inert gas applications. It is made from carbon fibers processed to withstand extreme heat.

It is an absorptive insulator, meaning it soaks up heat and contains it. Graphite is favored for its excellent performance at temperatures exceeding 2200°C and its structural integrity.

Ceramic Fiber Insulation

Ceramic fiber insulation is composed of materials like alumina or alumina-silica. It is also an absorptive insulator, similar to graphite, but is typically used for lower-temperature applications, generally below 1700°C.

It is often more affordable than graphite and can be used in furnaces that may occasionally be exposed to air at high temperatures, where graphite would quickly oxidize.

All-Metal Reflective Shields

Unlike graphite or ceramic, an all-metal hot zone does not absorb heat. Instead, it consists of multiple layers of polished metal sheets (like molybdenum, tungsten, or stainless steel) that reflect radiant heat back into the workload.

This design is prized for its exceptional cleanliness. Because metals have very low vapor pressure and do not contain binders, they introduce virtually no contamination into the vacuum environment, making them ideal for ultra-high vacuum and sensitive processes.

Understanding the Trade-offs

The choice of insulation is rarely straightforward and involves balancing performance, process requirements, and cost.

Temperature vs. Material Choice

Your furnace's maximum operating temperature is the first and most important constraint. Ceramic fibers are cost-effective for moderate temperatures, while graphite and all-metal shields are required for processes running above 1800°C.

Vacuum Purity and Outgassing

For applications like medical implants, aerospace electronics, or semiconductor components, process purity is paramount. All-metal shields offer the lowest outgassing and cleanest environment.

Ceramic fibers can shed microscopic particles, and the binders used within them can be a source of contamination. Graphite, while clean, can introduce carbon into the furnace atmosphere, which may be undesirable for certain materials.

Cost and Longevity

Initial cost is often a driving factor. Generally, ceramic fiber is the least expensive, followed by graphite, with all-metal hot zones being the most significant investment.

However, all-metal shields are durable, resistant to mechanical damage, and can be cleaned, offering a long service life that can offset the higher initial price. Graphite can be brittle, and both graphite and ceramic can be susceptible to damage.

Making the Right Choice for Your Application

Selecting the optimal insulation requires aligning the material's properties with your primary process goal.

- If your primary focus is high-purity vacuum and cleanliness (e.g., medical, electronics): All-metal reflective shields are the superior choice due to minimal outgassing.

- If your primary focus is very high-temperature processing (>2000°C) in an inert atmosphere: Graphite-based insulation provides the best thermal performance and stability.

- If your primary focus is general-purpose heat treating at moderate temperatures (<1700°C): Ceramic fiber insulation offers a reliable and highly cost-effective solution.

Ultimately, understanding these fundamental trade-offs empowers you to specify an insulation package that delivers the performance, purity, and efficiency your application demands.

Summary Table:

| Insulation Type | Max Temperature | Key Features | Ideal Applications |

|---|---|---|---|

| Graphite-Based | >2200°C | High thermal stability, absorptive | High-temperature inert gas processes |

| Ceramic Fiber | <1700°C | Cost-effective, resistant to oxidation | General-purpose heat treating |

| All-Metal Reflective | Varies by metal | Ultra-clean, low outgassing | Medical, electronics, high-purity processes |

Ready to enhance your lab's performance with the right vacuum furnace insulation? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for optimal temperature control, purity, and efficiency. Contact us today to discuss how we can support your specific application!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency