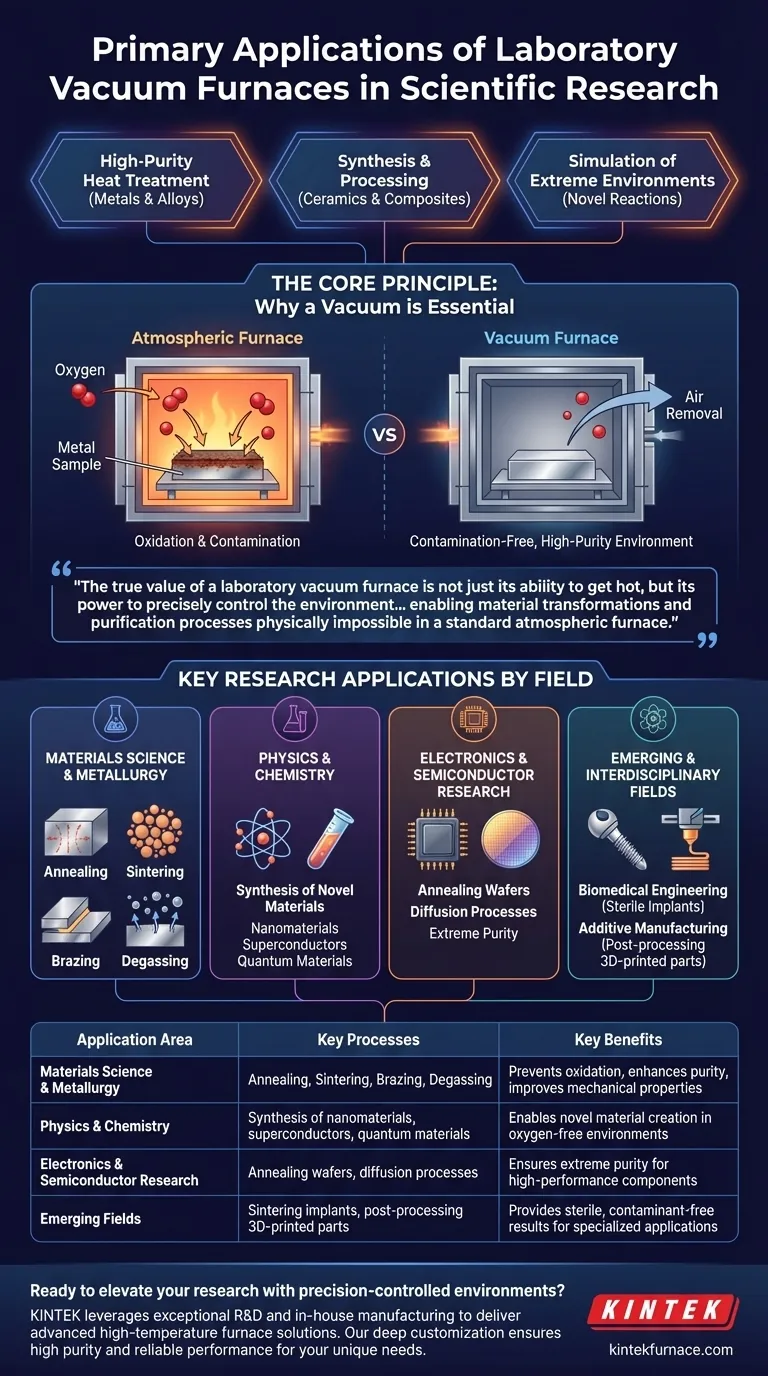

In scientific research, laboratory vacuum furnaces are primarily used for three key purposes: the high-purity heat treatment of metals and alloys, the synthesis and processing of advanced materials like ceramics and composites, and the simulation of extreme environments to study novel chemical and physical reactions. Their ability to create a controlled, contamination-free atmosphere at high temperatures is essential for developing materials with specific, enhanced properties.

The true value of a laboratory vacuum furnace is not just its ability to get hot, but its power to precisely control the environment. By removing reactive gases like oxygen, it enables material transformations and purification processes that are physically impossible to achieve in a standard atmospheric furnace.

The Core Principle: Why a Vacuum is Essential

To understand the applications, you must first understand the fundamental problem a vacuum furnace solves. It creates an environment nearly devoid of air and other gases, which has profound implications for materials at high temperatures.

Preventing Oxidation and Contamination

Most materials, especially metals, will rapidly react with oxygen at elevated temperatures. This process, called oxidation, forms a brittle, undesirable layer on the material's surface, altering its chemical and mechanical properties.

A vacuum furnace pumps out the air, removing the oxygen and nitrogen that cause these unwanted reactions. This ensures that the material's integrity and purity are maintained throughout the heating process.

Enabling High-Purity Processes

Certain processes, like joining metals or removing trapped gases, require an immaculate environment. A vacuum provides the clean slate needed for these sensitive operations to succeed.

This is critical in fields like aerospace and medical implants, where even microscopic impurities can lead to catastrophic component failure.

Key Research Applications by Field

By leveraging this controlled environment, researchers across multiple disciplines can push the boundaries of material science and chemistry.

Materials Science and Metallurgy

This is the most common domain for vacuum furnaces. They are used to fundamentally alter and improve the properties of materials.

Key processes include:

- Annealing: Heating and slowly cooling a material to reduce its hardness, increase its ductility, and relieve internal stresses.

- Sintering: Fusing powdered materials (like ceramics or metal powders) into a solid mass using heat below the melting point.

- Brazing: Joining two or more metal items by melting and flowing a filler metal into the joint, where the vacuum prevents oxides from interfering with the bond.

- Degassing: Removing dissolved gases from a material, which is critical for components used in high-vacuum or electronic applications.

Physics and Chemistry

In fundamental research, vacuum furnaces are used as small-scale reactors to create entirely new substances or study their behavior under specific conditions.

This includes the synthesis of novel materials such as nanomaterials, high-temperature superconductors, and advanced quantum materials that can only be formed in an oxygen-free environment.

Electronics and Semiconductor Research

The performance of electronic components depends on extreme material purity. Vacuum furnaces are indispensable for this.

Applications include the annealing of semiconductor wafers to repair crystal damage from ion implantation and diffusion processes where dopants are introduced into the wafer in a highly controlled manner.

Emerging and Interdisciplinary Fields

The utility of vacuum furnaces is expanding into new areas of research.

In biomedical engineering, they are used to sinter biocompatible implants made from materials like titanium alloys, ensuring they are sterile and free of surface contaminants. In additive manufacturing, they are used for post-processing 3D-printed metal parts to relieve stress and improve their final density and strength.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Their primary drawback is complexity and cycle time.

Achieving and maintaining a high vacuum requires sophisticated pumps and seals, which adds cost and maintenance overhead compared to a standard furnace.

Furthermore, the process of pumping down the chamber to the target vacuum level and later backfilling it for cooling adds significant time to each thermal cycle. This makes them less suitable for high-throughput applications where speed is the only priority.

Making the Right Choice for Your Goal

The specific process you use depends entirely on your research objective. Select your application based on the material outcome you need to achieve.

- If your primary focus is improving mechanical properties: Use heat treatments like vacuum annealing for softness, quenching for hardness, or tempering for toughness.

- If your primary focus is creating a new solid material from powders: Use vacuum sintering to fuse particles of ceramics, metals, or composites into a dense final part.

- If your primary focus is joining dissimilar materials with high integrity: Use vacuum brazing to create clean, strong, and hermetic joints without melting the base components.

- If your primary focus is achieving maximum material purity: Use high-vacuum degassing or annealing to remove trapped gases and contaminants, especially for electronics or medical applications.

Ultimately, a laboratory vacuum furnace is a precision tool for controlling a material's destiny at the atomic level.

Summary Table:

| Application Area | Key Processes | Key Benefits |

|---|---|---|

| Materials Science & Metallurgy | Annealing, Sintering, Brazing, Degassing | Prevents oxidation, enhances purity, improves mechanical properties |

| Physics & Chemistry | Synthesis of nanomaterials, superconductors, quantum materials | Enables novel material creation in oxygen-free environments |

| Electronics & Semiconductor Research | Annealing wafers, diffusion processes | Ensures extreme purity for high-performance components |

| Emerging Fields (e.g., Biomedical, Additive Manufacturing) | Sintering implants, post-processing 3D-printed parts | Provides sterile, contaminant-free results for specialized applications |

Ready to elevate your research with precision-controlled environments? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your unique needs. Our product line—including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet the exacting demands of scientific research. Whether you're working with metals, ceramics, composites, or emerging materials, our furnaces ensure high purity, contamination-free processing, and reliable performance. Contact us today to discuss how we can support your innovative projects and help you achieve superior results in materials development and beyond!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density