An industrial vacuum heat treatment furnace facilitates the diffusion step by strictly controlling the atmospheric pressure and temperature to enable the thermal release of oxygen atoms from a pre-formed oxide layer. By maintaining a vacuum environment, the furnace allows these atoms to migrate from the surface scale into the metallic matrix of Ti-6Al-4V specimens, effectively hardening the alloy without the interference of atmospheric gases.

Core Takeaway The vacuum furnace serves as a precision control chamber that converts a static surface oxide layer into a deep, hardened diffusion zone. Its ability to maintain specific low-pressure conditions is the defining factor in determining the final depth, quality, and morphology of the Oxygen Boosted Diffusion (OBD) layer.

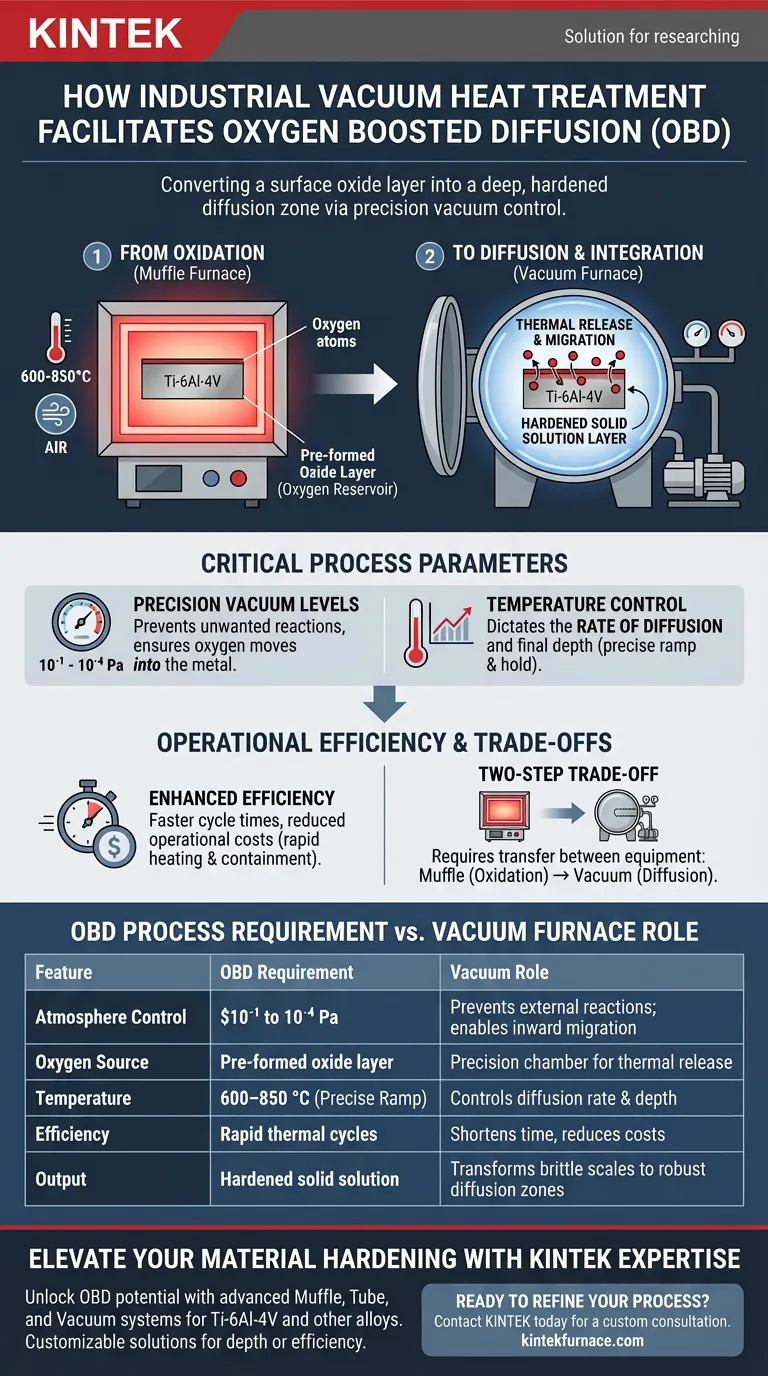

The Mechanics of Vacuum Diffusion

From Oxidation to Diffusion

The OBD process begins before the vacuum stage, where a muffle furnace creates a high-temperature air oxidation environment (600–850 °C). This creates a well-adhered oxide scale on the Ti-6Al-4V alloy, which acts as the oxygen reservoir.

Thermal Release and Migration

Once the pre-oxidized specimen enters the vacuum furnace, the environment shifts from generating oxide to transporting it. Under high heat and low pressure, oxygen atoms detach from the surface oxide layer.

Integration into the Matrix

These liberated oxygen atoms diffuse inward, penetrating the metallic matrix of the alloy. This migration transforms the brittle surface scale into a robust, hardened solid solution layer.

Critical Process Parameters

Precision Vacuum Levels

The furnace must maintain a specific vacuum range, typically between $10^{-1}$ and $10^{-4}$ Pa. This low-pressure environment is non-negotiable for preventing unwanted reactions with air and ensuring the oxygen moves into the metal rather than reacting externally.

Temperature Control

The furnace's ability to ramp up and hold precise temperatures dictates the rate of diffusion. Accurate temperature management ensures the oxygen penetrates to the correct depth to meet mechanical specifications.

Surface Morphology Management

The interaction between pressure and temperature directly impacts the surface finish (morphology). Deviations in these settings can lead to uneven hardening or surface defects, making the furnace’s precision control system vital for quality assurance.

Operational Efficiency and Trade-offs

Enhanced Cycle Times

Vacuum heat treatment furnaces generally offer faster cycle times than conventional alternatives. They can reach the necessary diffusion temperatures more rapidly, significantly shortening the overall processing time.

Energy and Cost Implications

Because these furnaces are designed for rapid heating and precise thermal containment, they are often more energy-efficient. This efficiency translates to reduced operational costs over the lifespan of the equipment.

Understanding the Trade-offs

While highly effective, the OBD process is dependent on a two-step equipment chain. You cannot achieve this specific diffusion mechanism in the initial muffle furnace, nor can you easily form the initial oxide layer in the vacuum furnace. The primary "cost" is the logistical necessity of transferring parts between two distinct pieces of equipment—the muffle furnace for oxidation and the vacuum furnace for diffusion.

Making the Right Choice for Your Goal

To maximize the effectiveness of the OBD process, you must align your furnace operations with your specific material requirements.

- If your primary focus is Hardening Depth: Prioritize a vacuum furnace with high-precision pressure controls capable of holding stable high-vacuum states ($10^{-4}$ Pa) for extended periods.

- If your primary focus is Process Efficiency: Leverage the vacuum furnace’s rapid heating capabilities to reduce cycle times, but ensure the initial oxide layer formed in the muffle furnace is sufficiently thick to support faster diffusion.

- If your primary focus is Versatility: Select a vacuum furnace capable of performing secondary services like outgassing, annealing, or vacuum quenching to maximize equipment utilization between OBD cycles.

The success of the Oxygen Boosted Diffusion process relies not just on heat, but on the vacuum furnace's ability to precisely manage the migration of oxygen atoms into the alloy's core.

Summary Table:

| Feature | OBD Process Requirement | Vacuum Furnace Role |

|---|---|---|

| Atmosphere Control | $10^{-1}$ to $10^{-4}$ Pa | Prevents external reactions; enables inward oxygen migration |

| Oxygen Source | Pre-formed oxide layer | Acts as a precision chamber to thermally release oxygen atoms |

| Temperature | 600–850 °C (Precise Ramp) | Controls the rate of diffusion and final hardening depth |

| Efficiency | Rapid thermal cycles | Shortens processing time and reduces operational costs |

| Output | Hardened solid solution | Transforms brittle scales into robust, deep diffusion zones |

Elevate Your Material Hardening with KINTEK Expertise

Unlock the full potential of Oxygen Boosted Diffusion (OBD) with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, and Vacuum systems specifically designed to handle the rigorous two-step oxidation and diffusion requirements of Ti-6Al-4V and other alloys.

Whether you need to maximize hardening depth or optimize process efficiency, our customizable lab and industrial high-temp furnaces provide the stability and control your research demands.

Ready to refine your heat treatment process? Contact KINTEK today for a custom consultation and see how our tailored systems can transform your production quality.

Visual Guide

References

- Yujie Xu, Jianming Gong. Effect of Temperature, Vacuum Condition and Surface Roughness on Oxygen Boost Diffusion of Ti–6Al–4V Alloy. DOI: 10.3390/coatings14030314

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How is vacuum annealing beneficial for high-purity aluminum foil production? Achieve Superior Purity and Performance

- Why is the precise control of H2 and C2H2 flow rates essential in plasma carburizing of AISI 316L? Master the S-Phase

- How do vacuum sintering furnaces compare to traditional furnaces? Unlock Superior Material Quality and Control

- What role does an industrial high-temperature vacuum furnace play in the post-treatment of semiconductor nanocrystals?

- Why are vacuum ovens and argon gas protection necessary for MXene monoliths? Ensure Density and Chemical Integrity

- In which industries are vacuum sintering furnaces commonly used? Essential for High-Performance Materials

- Why is a vacuum drying oven necessary for CTF precursors? Preserve Structural Integrity with Precise Heat Control

- What are the two main types of vacuum furnace chillers? Choose the Best for Your Lab's Efficiency