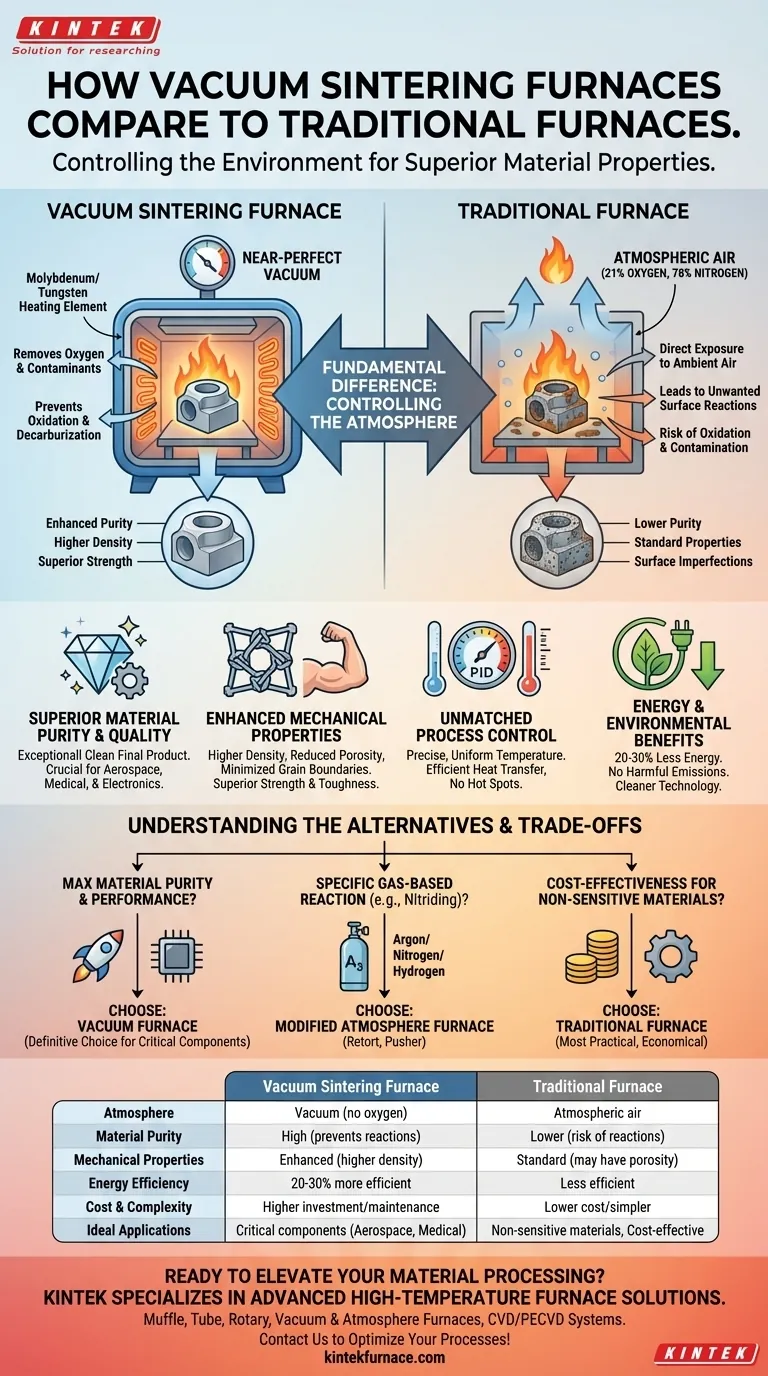

At their core, vacuum sintering furnaces outperform traditional furnaces by fundamentally changing the environment in which a material is heated. Instead of heating in open air, they create a vacuum to remove oxygen and other contaminants, which prevents oxidation, enhances material purity, and allows for superior control over the final product's mechanical properties.

The choice between a vacuum furnace and a traditional one is not just about applying heat. It is about deciding how much control you need over the material's environment. Vacuum furnaces offer the ultimate level of control, resulting in unparalleled material quality and process precision.

The Fundamental Difference: Controlling the Atmosphere

The primary distinction between these furnace types lies in how they manage the atmosphere surrounding the material during the heating cycle. This single factor dictates the quality, purity, and properties of the finished part.

How a Traditional Furnace Works

A traditional furnace operates at atmospheric pressure. Materials are heated in the presence of ambient air, which consists of approximately 21% oxygen, 78% nitrogen, and other trace gases. This direct exposure can lead to unwanted chemical reactions on the material's surface.

How a Vacuum Furnace Works

A vacuum furnace first seals the material in a chamber and then uses a system of pumps to remove the air and create a vacuum. Only after this near-perfect environment is achieved do the heating elements—often made of molybdenum or tungsten—raise the temperature. This process effectively eliminates the possibility of contamination from atmospheric gases.

The Impact: Eliminating Unwanted Reactions

By removing oxygen, a vacuum furnace prevents oxidation, a reaction that can compromise a material's surface integrity and strength. It also stops decarburization (the loss of carbon content in steel), ensuring the material retains its intended hardness and durability.

Key Advantages of Vacuum Sintering

Operating within a vacuum unlocks several significant benefits that are difficult or impossible to achieve with traditional atmospheric heating.

Superior Material Purity and Quality

Without oxygen, moisture, or other contaminants to react with, the final product is exceptionally clean. This high level of purity is non-negotiable for critical components in the aerospace, medical, and electronics industries, where material integrity is paramount.

Enhanced Mechanical Properties

The vacuum environment promotes better diffusion and bonding between material particles during sintering. This results in parts with higher density, reduced porosity, and minimized grain boundaries, which directly translates to superior strength, toughness, and fatigue resistance.

Unmatched Process Control

Vacuum furnaces enable extremely precise and uniform temperature control, often using advanced PID (Proportional-Integral-Derivative) control systems. The absence of air allows for more efficient and even heat transfer, eliminating hot spots and ensuring the entire part is treated consistently.

Energy and Environmental Benefits

Vacuum furnaces are inherently more efficient. Due to improved heat transfer and insulation within the sealed chamber, they can require 20-30% less energy than comparable atmospheric furnaces. Furthermore, they produce no harmful emissions, making them a cleaner, more environmentally friendly technology.

Understanding the Alternatives and Trade-offs

While vacuum furnaces offer clear advantages, they are not the universal solution. The complexity and cost mean that other furnace types retain an important role.

When Traditional Furnaces Suffice

For materials that are not sensitive to oxidation or for applications where surface finish is not a critical parameter, a traditional atmospheric furnace is often the most cost-effective and straightforward solution.

The Role of Modified Atmosphere Furnaces

A modified atmosphere furnace, such as a retort or pusher furnace, offers a middle ground. Instead of creating a vacuum, it purges the air and replaces it with a specific, controlled gas like argon, nitrogen, or hydrogen. This is ideal for processes that require a specific gas-based reaction (like nitriding) or simply need an inert, non-oxidizing environment without the full complexity of a vacuum.

The Cost and Complexity Factor

Vacuum furnaces are sophisticated systems involving vacuum pumps, tight seals, and complex control instrumentation. This results in a higher initial investment and more demanding maintenance requirements compared to simpler atmospheric or modified atmosphere furnaces.

Making the Right Choice for Your Application

Selecting the correct furnace technology requires aligning its capabilities with your specific material requirements and production goals.

- If your primary focus is maximum material purity and performance: A vacuum furnace is the definitive choice for creating components with the highest possible density, strength, and cleanliness.

- If your primary focus is cost-effectiveness for non-sensitive materials: A traditional atmospheric furnace remains the most practical and economical solution.

- If your primary focus is a specific gas-based reaction or inert protection: A modified atmosphere furnace provides the targeted environment you need without the full requirements of a vacuum system.

Ultimately, choosing the right furnace is about selecting the precise level of environmental control your material demands to achieve its desired outcome.

Summary Table:

| Aspect | Vacuum Sintering Furnace | Traditional Furnace |

|---|---|---|

| Atmosphere | Vacuum (no oxygen/contaminants) | Atmospheric air (21% oxygen) |

| Material Purity | High (prevents oxidation, decarburization) | Lower (risk of surface reactions) |

| Mechanical Properties | Enhanced (higher density, strength) | Standard (may have porosity) |

| Energy Efficiency | 20-30% more efficient | Less efficient |

| Cost & Complexity | Higher initial investment and maintenance | Lower cost and simpler operation |

| Ideal Applications | Aerospace, medical, electronics (critical components) | Non-sensitive materials, cost-effective processes |

Ready to elevate your material processing with precision and purity? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—with strong deep customization capabilities to meet your exact experimental requirements. Whether you're in aerospace, medical, or electronics, our vacuum sintering furnaces deliver unparalleled control and quality. Don't settle for less—contact us today to discuss how we can optimize your processes and drive your innovations forward!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness