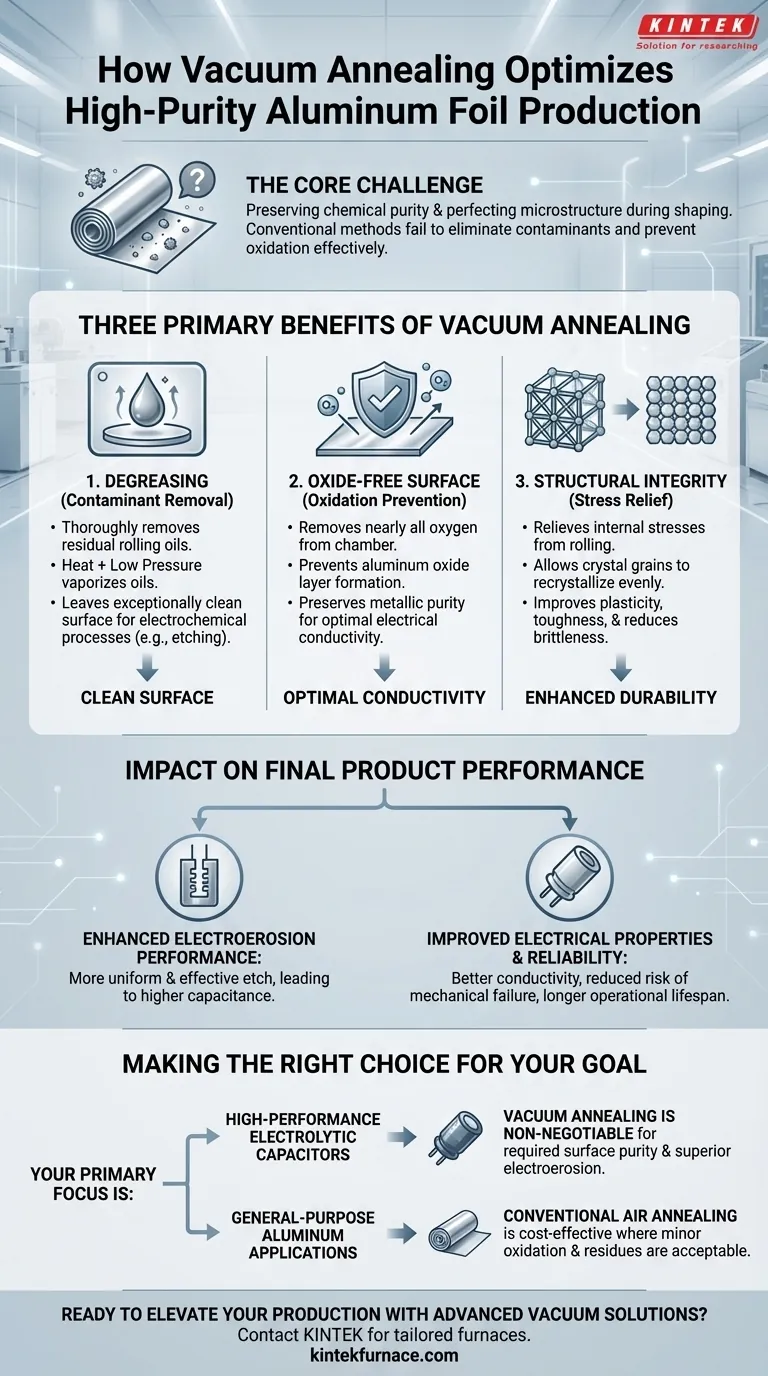

In high-purity aluminum foil production, vacuum annealing is a critical process that delivers three primary benefits: it thoroughly removes residual rolling oils, prevents surface oxidation, and relieves internal stresses from manufacturing. This combination ensures the foil achieves the pristine surface purity and structural integrity required for high-performance applications like electrolytic capacitors.

The core challenge with high-purity aluminum foil is not just shaping it, but preserving its chemical purity and perfecting its microstructure. Vacuum annealing solves this by creating a controlled environment that eliminates contaminants and refines the material's properties in a way that conventional heating methods cannot.

The Core Functions of Vacuum Annealing

To understand its benefits, we must look at how the vacuum environment fundamentally changes the annealing process. It isn't just about heating the metal; it's about what is removed and what is prevented during that heating.

Contaminant Removal and Surface Purity

During the rolling process, oils are used to lubricate and cool the aluminum. Trace amounts of these oils inevitably remain trapped on the foil's surface and between the layers of a tightly wound roll.

Vacuum annealing excels at degreasing. The combination of heat and low pressure causes these residual oils to vaporize, allowing the vacuum system to pump them away, leaving an exceptionally clean surface.

This cleanliness is essential for subsequent electrochemical processes, such as the etching required to create high-surface-area capacitor anodes.

Preventing Surface Oxidation

Aluminum is highly reactive with oxygen, especially at the elevated temperatures required for annealing.

In a conventional furnace, a layer of aluminum oxide would instantly form on the foil's surface. A vacuum furnace removes nearly all the oxygen from the chamber, preventing oxidation and preserving the foil's metallic purity.

This oxide-free surface is critical for ensuring optimal electrical conductivity and performance in the final product.

Relieving Internal Stress for Structural Integrity

The mechanical rolling process introduces significant internal stress into the aluminum's crystal structure. This stress can make the foil brittle and unstable, leading to defects in later manufacturing stages.

Annealing relieves this stress by allowing the crystal grains to recrystallize into a more uniform and stable arrangement. This improves the material's plasticity and toughness, making it more durable and predictable for processing and use.

Ensuring Uniformity Through Precise Temperature Control

Vacuum furnaces provide highly uniform heating in a controlled environment. For extremely thin foils, this prevents hot spots, warping, or inconsistent grain structures across the roll, ensuring every part of the material meets the exact same specifications.

Understanding the Trade-offs

While vacuum annealing provides superior results, it's important to understand its position relative to conventional methods. The choice is a classic trade-off between processing cost and final product quality.

The Drawback: Cost and Complexity

Vacuum furnaces represent a higher capital investment and have greater operational complexity than standard air furnaces. The process cycles can also be longer due to the time required to pump the chamber down to the target vacuum level.

The Critical Advantage: Unmatched Quality

For demanding applications, the quality improvements are not just beneficial—they are mandatory. Conventional annealing simply cannot produce foil with the low contamination and zero surface oxidation required for high-performance electronics.

The degreasing and oxidation prevention offered by a vacuum environment are what elevate the material from a standard commodity to a high-value technical component.

How This Impacts Final Product Performance

The benefits of vacuum annealing are not merely theoretical. They have a direct and measurable impact on the quality and reliability of the final electronic component.

Enhancing Electroerosion Performance

For aluminum electrolytic capacitors, the foil must be electrochemically etched to dramatically increase its surface area. A clean, pure, oxide-free surface, as produced by vacuum annealing, allows for a more uniform and effective etch.

This results in higher capacitance and better overall performance from the finished capacitor.

Improving Electrical Properties and Reliability

By eliminating surface contaminants and preventing oxide layers, vacuum annealing ensures the aluminum foil has the best possible electrical properties. The improved structural integrity from stress relief also reduces the risk of mechanical failure during capacitor winding and assembly.

This translates directly to a more reliable, higher-quality final product with a longer operational lifespan.

Making the Right Choice for Your Goal

To select the correct process, you must align the method with your final objective.

- If your primary focus is high-performance electrolytic capacitors: Vacuum annealing is non-negotiable for achieving the required surface purity and superior electroerosion performance.

- If your primary focus is general-purpose aluminum applications: Conventional air annealing is often a more cost-effective solution where minor surface oxidation and residual contaminants are acceptable.

- If your primary focus is maximizing material stability for delicate subsequent processing: The superior stress relief and structural uniformity from vacuum annealing are critical to prevent defects and ensure consistency.

Ultimately, choosing the right thermal process is fundamental to guaranteeing the performance and reliability of your final product.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Contaminant Removal | Eliminates residual oils for clean surfaces, improving electrochemical etching |

| Oxidation Prevention | Maintains metallic purity, ensuring optimal electrical conductivity |

| Stress Relief | Enhances plasticity and toughness, reducing brittleness and defects |

| Uniform Heating | Prevents warping and ensures consistent grain structure across the foil |

Ready to elevate your high-purity aluminum foil production with advanced vacuum annealing solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored vacuum furnaces can enhance your material purity, reliability, and performance for demanding applications like electrolytic capacitors!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity