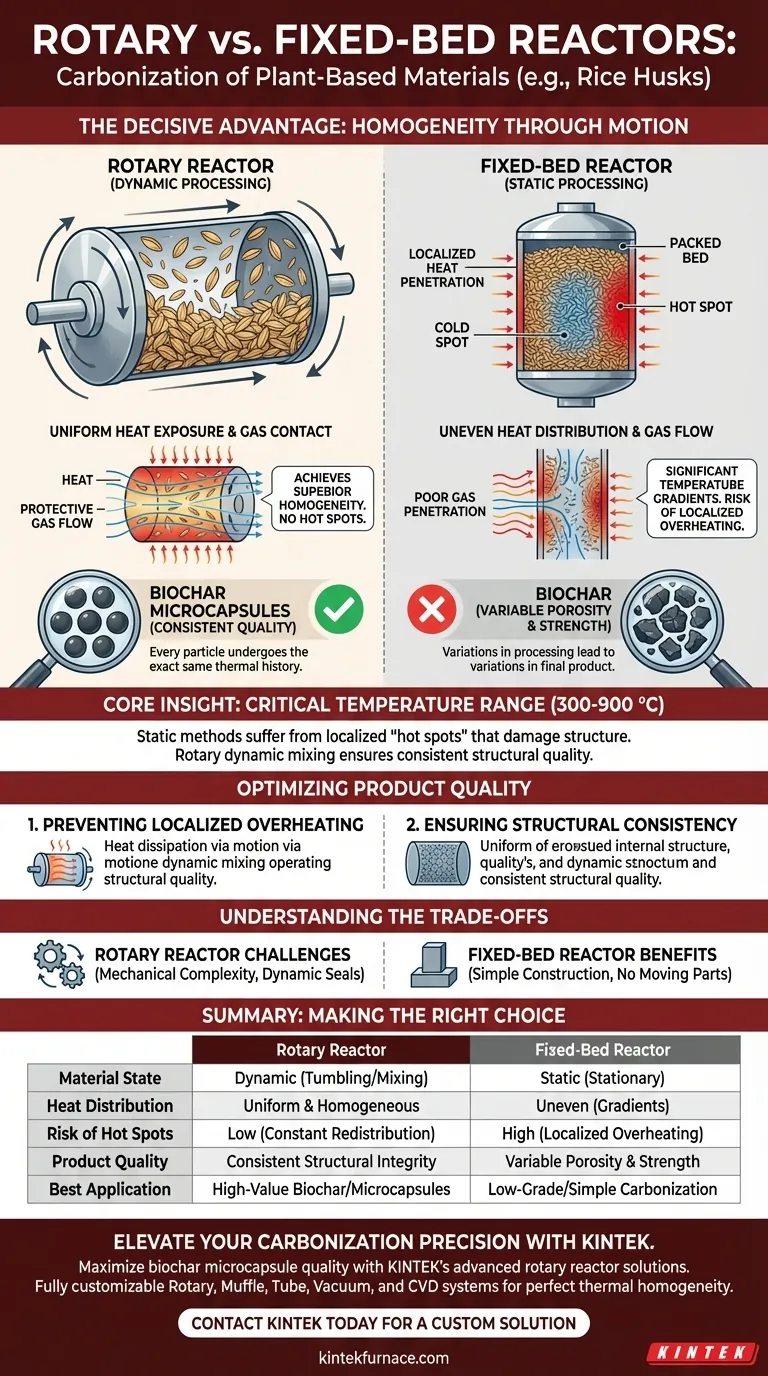

The decisive advantage of a rotary reactor over a fixed-bed reactor for carbonizing rice husks lies in its ability to achieve superior homogeneity through continuous mechanical motion. While a fixed-bed reactor keeps material static—often leading to uneven heat distribution—a rotary reactor tumbles the biomass, ensuring uniform exposure to heat and protective gases.

Core Insight: In the critical temperature range of 300 to 900 °C, static processing methods often suffer from localized "hot spots" that damage product structure. A rotary reactor solves this by dynamically mixing the raw material, ensuring that every particle undergoes the exact same thermal history to produce biochar microcapsules of consistent structural quality.

The Mechanics of Uniformity

The Limit of Static Processing

In a standard fixed-bed reactor, the biomass (such as rice husks) remains stationary throughout the process. Heat must penetrate the material via conduction, which is often inefficient in porous plant fibers.

This static arrangement frequently leads to significant temperature gradients. Material closest to the heat source may burn or overheat, while material in the center may remain under-processed.

Achieving Dynamic Contact

The rotary reactor introduces a continuous rotation mechanism. This creates a tumbling motion that constantly redistributes the rice husks within the chamber.

According to technical observations, this motion ensures "thorough contact" between three critical elements: the raw material, the heat source, and the protective gas. This interaction is virtually impossible to achieve in a packed, static bed.

Optimizing Product Quality

Preventing Localized Overheating

One of the most significant risks in carbonization is localized overheating. In a fixed bed, trapped heat can degrade the biomass beyond the desired carbonization point, effectively destroying the microstructure.

The rotary reactor’s dynamic mixing effectively prevents this. By constantly moving the particles, heat is dissipated evenly, ensuring no single section of the batch is exposed to excessive temperatures for prolonged periods.

Ensuring Structural Consistency

For applications involving biochar microcapsules, the internal structure of the carbonized husk is paramount. Variations in processing lead to variations in the final product's porosity and strength.

The rotary process guarantees "structural consistency." Because the tumbling motion eliminates uneven carbonization, the resulting biochar exhibits a uniform quality that is difficult to replicate in static systems.

Understanding the Trade-offs

Mechanical Complexity

While the rotary reactor offers superior product quality, it introduces mechanical complexity. Fixed-bed reactors have no moving parts, making them simpler to construct and maintain.

Sealing and Atmosphere Control

Rotary reactors require dynamic seals to maintain the protective gas atmosphere while the drum rotates. This adds a layer of engineering difficulty compared to the sealed, static vessel of a fixed-bed reactor.

Making the Right Choice for Your Goal

When selecting a reactor type for plant-based carbonization, align your choice with your specific product requirements:

- If your primary focus is Product Consistency: Choose the rotary reactor to ensure uniform heat transfer and high-quality, structurally sound biochar microcapsules.

- If your primary focus is System Simplicity: A fixed-bed reactor may suffice for lower-grade applications where slight variations in carbonization are acceptable.

Ultimately, for high-value biochar microcapsules where structural integrity is non-negotiable, the dynamic mixing of a rotary reactor is the superior technical solution.

Summary Table:

| Feature | Rotary Reactor | Fixed-Bed Reactor |

|---|---|---|

| Material State | Dynamic (Tumbling/Mixing) | Static (Stationary) |

| Heat Distribution | Uniform & Homogeneous | Uneven (Temperature Gradients) |

| Risk of Hot Spots | Low (Constant Redistribution) | High (Localized Overheating) |

| Product Quality | Consistent Structural Integrity | Variable Porosity & Strength |

| Best Application | High-Value Biochar/Microcapsules | Low-Grade/Simple Carbonization |

Elevate Your Carbonization Precision with KINTEK

Maximize the quality of your biochar microcapsules with KINTEK’s advanced rotary reactor solutions. Backed by expert R&D and world-class manufacturing, we offer Rotary, Muffle, Tube, Vacuum, and CVD systems—all fully customizable to meet your specific laboratory or industrial high-temperature needs.

Don't settle for uneven results. Let our experts help you design a system that ensures perfect thermal homogeneity and structural consistency for your plant-based materials.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Alibek Mutushev, Dauren Mukhanov. Development and application of microcapsules based on rice husk and metallurgical sludge to improve soil fertility. DOI: 10.1038/s41598-024-73329-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is the Rotary Tube Tilt Furnace used in carbon activation processes? Achieve Precise Control for High-Quality Activated Carbon

- What safety measures are typically included in a rotary tube sintering furnace? Ensure Reliable High-Temperature Processing

- How can the internal configuration of a rotary kiln be adjusted? Optimize Your Thermal Process Efficiency

- What is the temperature range of some rotary tube furnaces? Achieve Uniform Heating Up to 1200°C

- What are the design classifications of rotary tube furnaces? Optimize Your Lab or Industrial Process

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- How does a rotary tube furnace operate in terms of fuel and heating? Discover Dynamic Heating for Uniform Results

- What are the drawbacks of indirect-fired rotary kilns? Explore Key Limitations and Trade-offs