In practice, many rotary tube furnaces operate at temperatures up to 1000°C, with certain models reaching a maximum of 1200°C. This range makes them suitable for a wide variety of thermal processing applications, but the specific temperature limit is often determined by the material of the furnace's tube, such as stainless steel or quartz.

The key takeaway is not just the maximum temperature, but how rotary tube furnaces achieve exceptionally uniform heat. Their defining feature is the combination of controlled rotation and precise digital temperature management, which ensures every particle of a material is processed consistently.

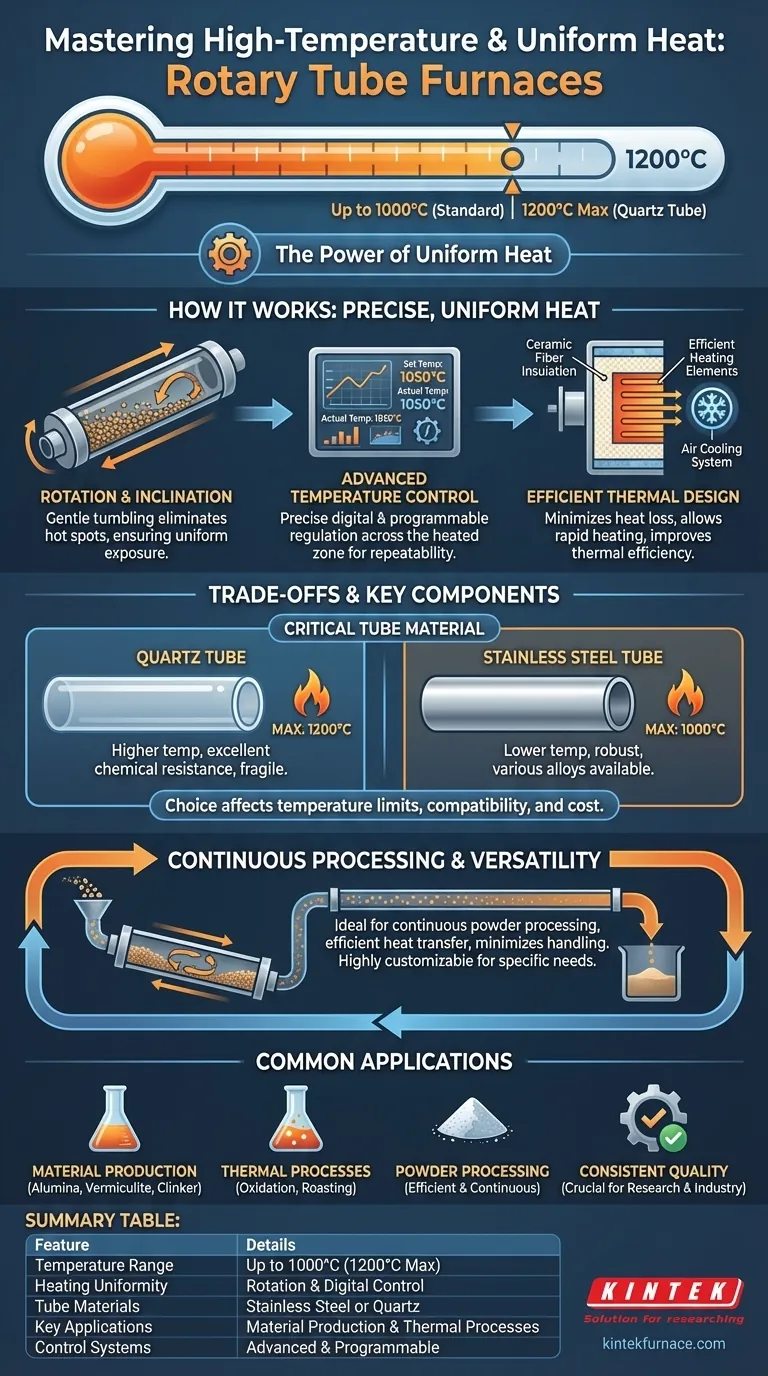

How Rotary Tube Furnaces Achieve Precise, Uniform Heat

The effectiveness of a rotary tube furnace comes from its unique design, which is engineered for dynamic and homogenous heating of loose or powdered materials.

The Core Principle: Rotation and Inclination

A long, cylindrical barrel is inclined at a slight angle and rotates slowly. This gentle, continuous tumbling action ensures the material inside moves constantly.

As the material moves, every particle is repeatedly exposed to the furnace's heating elements, eliminating hot spots and ensuring uniform heat exposure throughout the entire batch.

Advanced Temperature Control

Modern rotary tube furnaces feature advanced digital controllers for precise temperature regulation. These systems maintain a uniform temperature across the entire heated zone.

Many include programmable controllers that can store complex heating profiles with multiple steps or segments. This allows for highly customized and repeatable thermal processing, which is critical for experimental accuracy and consistent production quality.

Efficient Thermal Design

These furnaces use high-quality ceramic fiber insulation and efficient heating elements. This design minimizes heat loss, reduces energy consumption, and allows for rapid heating.

Some models also incorporate an air cooling system to help balance the temperature field and improve overall thermal efficiency, ensuring the process is both effective and economical.

Understanding the Trade-offs and Key Components

While powerful, the capabilities of a rotary tube furnace are directly tied to its construction and intended use case. Understanding these factors is critical for selecting the right instrument.

The Critical Role of the Tube Material

The maximum operating temperature is most often limited by the work tube material. Tubes are commonly made from stainless steel or high-purity quartz.

Quartz tubes typically allow for higher operating temperatures (up to 1200°C), while various stainless steel alloys will have lower limits. The choice of material is a direct trade-off between temperature requirements, chemical compatibility, and cost.

Continuous Processing Advantage

The design is exceptionally well-suited for continuous or semi-continuous batch processing. As new material is fed into the higher end of the inclined tube, processed material exits at the lower end.

This is especially valuable in powder processing, as it enables efficient heat transfer over short durations and minimizes the need for manual material handling.

Customization and Versatility

Rotary tube furnaces are not a one-size-fits-all solution. They can often be customized in terms of the work tube's size and shape, the type of heating elements, the control system, and other construction materials to fit specific industrial or laboratory needs.

Common Applications

The unique combination of uniform heating and continuous material movement makes these furnaces ideal for specific tasks across research and industry.

Material Production

They are commonly used to produce materials like alumina, vermiculite, cement clinker, and iron ore pellets, where consistent properties throughout the final product are essential.

Thermal Processes

The controlled environment is perfect for thermal treatments such as oxidation and roasting of ores and other chemical compounds.

Making the Right Choice for Your Goal

To determine if a rotary tube furnace is the correct tool, match its core strengths to your primary objective.

- If your primary focus is high-temperature processing: Verify that the furnace's tube material, such as quartz, can safely and consistently operate at your target temperature.

- If your primary focus is process repeatability: Prioritize a model with an advanced, programmable digital controller to ensure identical thermal treatment for every batch.

- If your primary focus is continuous production of powders: This furnace design is uniquely suited for your goal, offering unparalleled uniformity and minimizing material handling.

Ultimately, a rotary tube furnace excels where dynamic, uniform, and continuous heating of loose materials is the most critical requirement.

Summary Table:

| Feature | Details |

|---|---|

| Temperature Range | Up to 1000°C standard, 1200°C max with quartz tubes |

| Heating Uniformity | Achieved via rotation, inclination, and digital control |

| Tube Materials | Stainless steel, quartz (affects max temperature) |

| Key Applications | Material production, oxidation, roasting, powder processing |

| Control Systems | Advanced digital, programmable for repeatability |

Elevate your thermal processing with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior uniformity and efficiency. Contact us today to discuss how we can optimize your processes!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing