To adjust the internal configuration of a rotary kiln, you manipulate key operational parameters and physical components. The primary adjustments involve altering the kiln's rotation speed, its slope or inclination, and the burner's output to control how long material stays inside, how it tumbles, and the amount of heat it is exposed to.

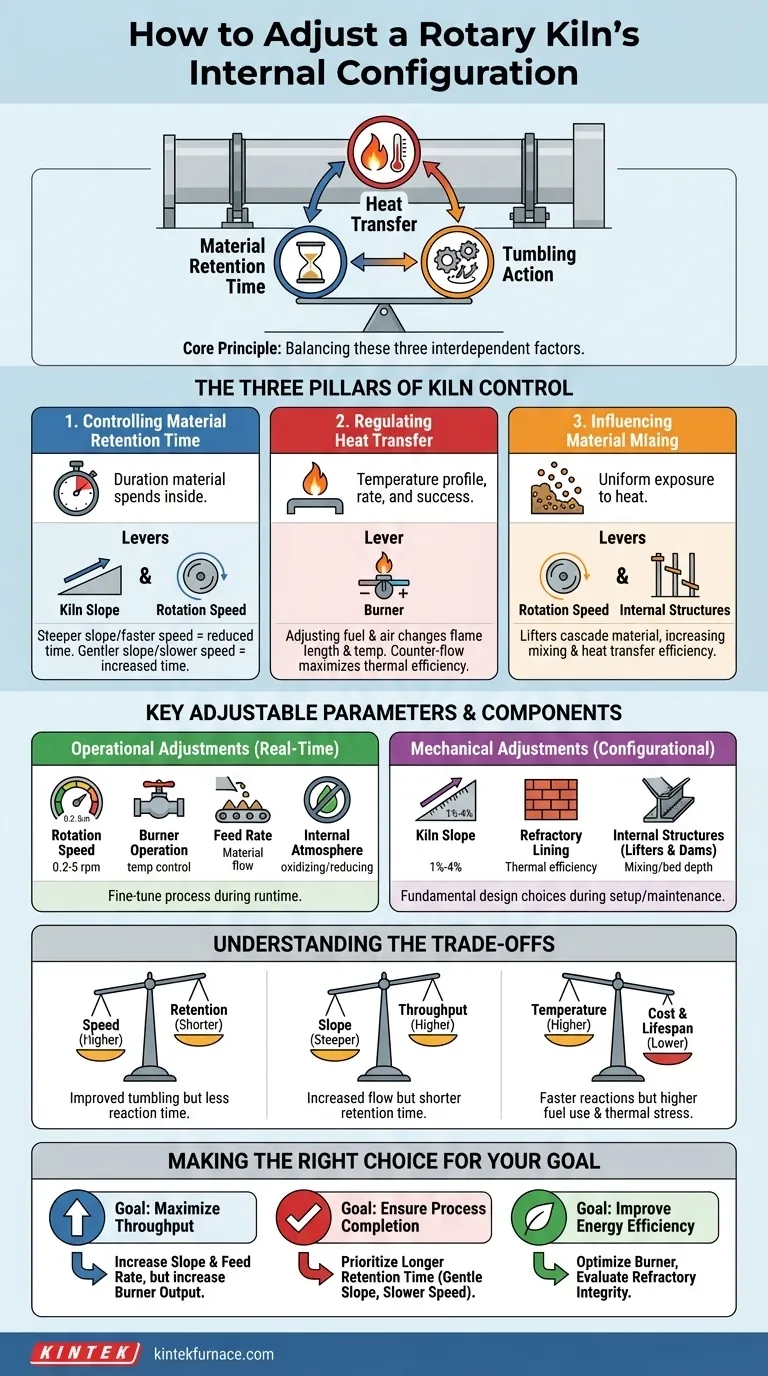

The core principle of rotary kiln adjustment is not about changing one component, but about balancing three interdependent factors: material retention time, heat transfer, and tumbling action. Mastering the interplay between these variables is the key to optimizing any thermal process.

The Three Pillars of Kiln Control

Optimizing a rotary kiln requires understanding how to influence the material's journey through the drum. This journey is governed by three fundamental pillars of control.

Controlling Material Retention Time

Retention time is the duration the material spends inside the kiln. It is the most critical factor for ensuring a complete chemical reaction or physical change.

The two main levers for controlling retention time are kiln slope and rotation speed. A steeper slope or faster rotation speed will move material through the kiln more quickly, reducing retention time. Conversely, a gentler slope and slower rotation will increase it.

Regulating Heat Transfer

The temperature profile inside the kiln dictates the rate and success of the process. Heat is primarily controlled by the burner located at the discharge end.

Adjusting the burner's fuel and air mixture changes the temperature and length of the flame, which in turn defines the heating zones within the kiln (drying, preheating, calcining). Most kilns use a counter-flow design, where heat flows against the material, to maximize thermal efficiency.

Influencing Material Mixing

Proper mixing, or tumbling, ensures that every particle is uniformly exposed to the heat. This is primarily influenced by the rotation speed of the kiln shell.

Beyond speed, the physical internal configuration can include lifters. These are metal fixtures welded to the inside of the kiln shell that lift material and cascade it through the hot gas stream, dramatically increasing mixing and heat transfer efficiency.

Key Adjustable Parameters and Components

Adjustments can be categorized as either operational (made during runtime) or mechanical (made during setup or major maintenance).

Operational Adjustments (Real-Time)

These are the parameters you can change on the fly to fine-tune the process.

- Rotation Speed: Typically ranges from 0.2 to 5 rpm. Increasing speed enhances tumbling but reduces retention time.

- Burner Operation: The primary control for temperature. Adjusting fuel input directly impacts the process temperature and energy consumption.

- Feed Rate: The rate at which new material is introduced. A higher feed rate requires corresponding adjustments to heat and retention time to maintain process quality.

- Internal Atmosphere: Kiln seals are critical for maintaining a controlled internal atmosphere (e.g., oxidizing or reducing), which is essential for certain chemical reactions.

Mechanical Adjustments (Configurational)

These are fundamental design choices that are set during installation or overhaul.

- Kiln Slope: The inclination of the drum, typically between 1% and 4%. This is a foundational parameter that dictates the baseline material flow rate.

- Refractory Lining: The internal brick or castable lining is a critical choice. Its material and thickness determine the kiln's thermal efficiency and protect the steel shell from extreme temperatures.

- Internal Structures (Lifters & Dams): Lifters are installed to improve mixing. Dams are refractory rings built inside the kiln to increase the bed depth of the material in a specific zone, thereby increasing retention time in that section.

Understanding the Trade-offs

Every adjustment involves a trade-off. A change designed to improve one aspect of performance will inevitably affect others.

Speed vs. Retention

Increasing rotation speed improves tumbling and can prevent material clumping. However, it also reduces the time the material has to absorb heat and react, potentially leading to an incomplete process if not balanced with other factors.

Slope vs. Throughput

A steeper slope increases the rate at which material moves through the kiln, allowing for higher throughput. The trade-off is a significantly shorter retention time, which may require a much higher process temperature to compensate.

Temperature vs. Cost and Lifespan

Raising the temperature can accelerate reactions and compensate for short retention times. However, this comes at the cost of higher fuel consumption and increased thermal stress on the refractory lining, potentially shortening its operational life.

Making the Right Choice for Your Goal

To effectively adjust your kiln, you must first define your primary objective.

- If your primary focus is maximizing throughput: Consider increasing the kiln slope and feed rate, but be prepared to increase burner output to ensure the material is fully processed in the shorter retention time.

- If your primary focus is ensuring process completion: Prioritize a longer retention time by using a gentler slope and slower rotation speed, allowing the material ample time to react at an efficient temperature.

- If your primary focus is improving energy efficiency: Optimize the burner for complete combustion and evaluate your refractory lining's integrity to minimize heat loss through the kiln shell.

By understanding these interconnected variables, you can move from simply operating your kiln to truly mastering your process.

Summary Table:

| Adjustment Type | Key Parameters | Key Effects |

|---|---|---|

| Operational | Rotation Speed, Burner Output, Feed Rate | Controls real-time tumbling, temperature, and material flow |

| Mechanical | Kiln Slope, Refractory Lining, Lifters/Dams | Sets baseline retention time, thermal efficiency, and mixing |

Master your thermal processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored rotary kilns, muffle furnaces, tube furnaces, and more. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can optimize your setup!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules