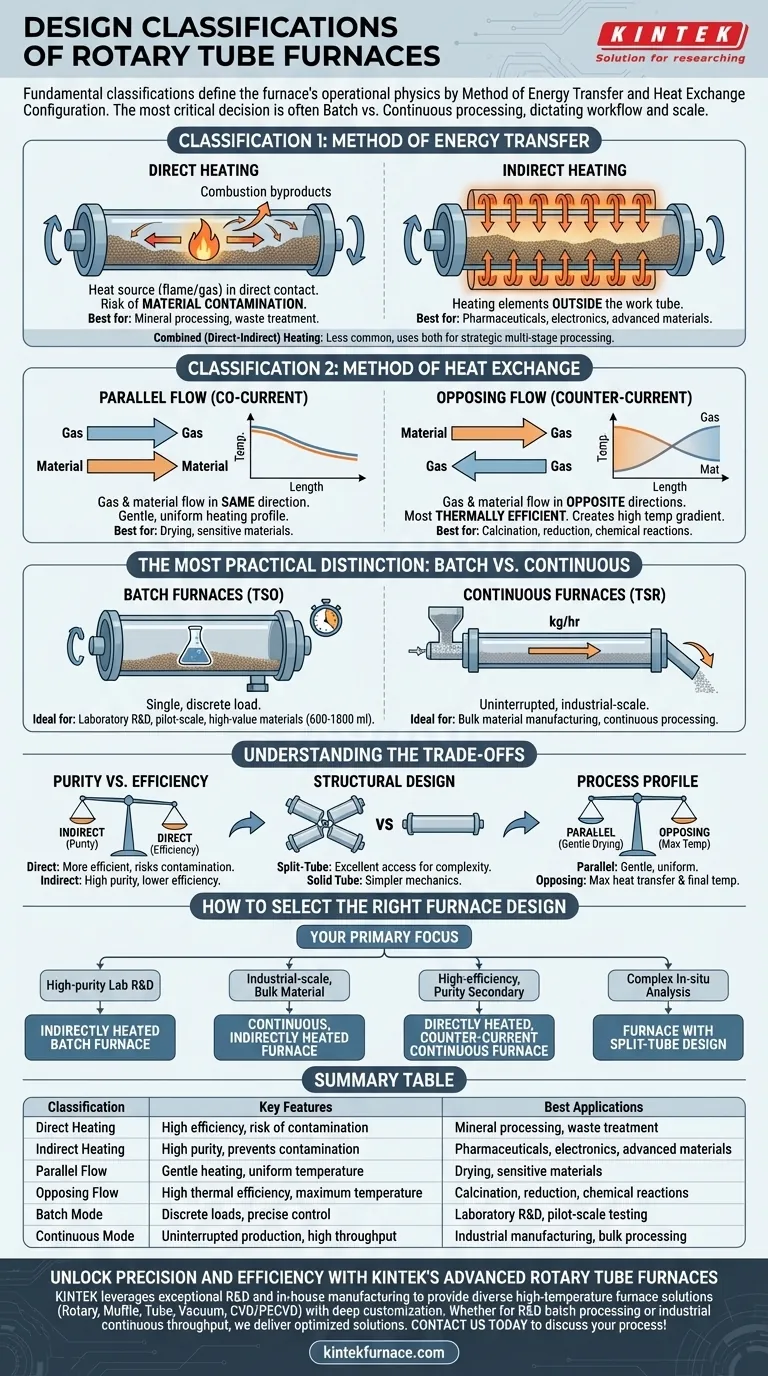

At a fundamental level, rotary tube furnaces are classified by their method of energy transfer and their heat exchange configuration. Energy transfer defines how heat reaches the material—either directly or indirectly—while the heat exchange method defines the flow dynamics between the process gas and the material, which can be parallel or opposing.

The formal classifications define the furnace's operational physics. However, your most critical decision will be choosing between a batch or continuous processing model, as this choice dictates your entire workflow, scale, and suitability for either laboratory research or industrial production.

Classification 1: Method of Energy Transfer

This classification describes how thermal energy from the heating elements is delivered to the material being processed inside the rotating tube.

Direct Heating

In a directly heated furnace, the heat source (such as a flame or hot gas) is in direct contact with the process material. This method is highly efficient from a thermal perspective.

However, it introduces the significant risk of material contamination from the combustion byproducts or process gas. It is typically reserved for applications where material purity is not the primary concern, such as in mineral processing or waste treatment.

Indirect Heating

This is the most common design for controlled applications. The heating elements are positioned outside the work tube, heating the tube's wall. The rotating tube then transfers heat to the material via conduction and radiation.

This method completely isolates the material from the heating source, ensuring high purity and preventing contamination. It is the standard for pharmaceuticals, electronics, and advanced materials research.

Combined (Direct-Indirect) Heating

Less common, a combined furnace uses both methods strategically. For example, it might use indirect heating for a sensitive initial drying phase and then introduce direct heating for a high-temperature calcination stage to maximize efficiency.

Classification 2: Method of Heat Exchange

This classification refers to the flow direction of the process gas relative to the flow direction of the solid material moving through the inclined tube.

Parallel Flow (Co-current)

The process gas and the solid material enter the furnace at the same end and travel in the same direction.

This configuration is excellent for processes like drying, where a rapid initial temperature drop in the gas is acceptable. It provides a more gentle heating profile as the temperature difference between the gas and material decreases along the length of the tube.

Opposing Flow (Counter-current)

The process gas and the solid material enter the furnace at opposite ends and travel towards each other. The hot gas enters where the material exits, and the cooler gas exits where the material enters.

This design is the most thermally efficient configuration. It creates a high temperature gradient that is ideal for driving chemical reactions to completion, such as calcination or reduction, and achieving the highest possible material temperature.

The Most Practical Distinction: Batch vs. Continuous

Beyond the physics of heat transfer, the most important design choice is the furnace's operational mode. This determines its scale and application.

Batch Furnaces (TSO)

Batch furnaces are designed to process a single, discrete load of material at a time. The tube is loaded, the process is run, and then the furnace is cooled before the material is removed.

These systems, with typical capacities from 600 to 1800 ml, are ideal for laboratory R&D, pilot-scale testing, and processing high-value materials where precise control over a small volume is critical.

Continuous Furnaces (TSR)

Continuous furnaces are designed for uninterrupted, industrial-scale production. Material is constantly fed into the furnace from a hopper and is discharged at the other end.

Their capacity is measured in throughput (kg/hr) rather than batch volume. These furnaces are the workhorses of bulk material manufacturing and continuous chemical processing.

Understanding the Trade-offs

Choosing a rotary furnace involves balancing competing priorities. Your application will determine which trade-offs are acceptable.

Purity vs. Efficiency

The core trade-off between energy transfer methods is clear: direct heating is more energy-efficient but risks contamination, while indirect heating ensures purity at the cost of lower thermal efficiency. For most technical applications, purity is non-negotiable, making indirect heating the default choice.

Structural Design: Split-Tube vs. Solid Tube

A key physical option is the split-tube design, where the furnace body is hinged to open lengthwise. This provides excellent access to the work tube for placing complex sample holders, sensors, or when the tube itself is part of an intricate apparatus. The trade-off is increased mechanical complexity compared to a simpler, solid-body furnace.

Process Profile: Gentle Drying vs. Maximum Temperature

The choice between parallel and opposing flow dictates the thermal profile. Parallel flow provides gentler, more uniform heating, ideal for sensitive materials or simple drying. Opposing flow maximizes heat transfer and final temperature, making it superior for driving endothermic reactions and achieving process completion.

How to Select the Right Furnace Design

Your final choice should be guided by your end goal.

- If your primary focus is high-purity lab research or R&D: You will almost certainly require an indirectly heated batch furnace to ensure process control and prevent contamination.

- If your primary focus is industrial-scale production of a bulk material: A continuous, indirectly heated furnace is your typical starting point for consistent quality and high throughput.

- If your primary focus is high-efficiency processing where purity is secondary: A directly heated, counter-current continuous furnace offers the best thermal performance for applications like mineral calcination.

- If your primary focus involves complex in-situ analysis or sample arrangements: A furnace with a split-tube design provides the necessary access that a solid-tube furnace cannot offer.

Understanding these core design principles empowers you to select a furnace that is not just functional, but perfectly aligned with your specific processing goals.

Summary Table:

| Classification | Key Features | Best Applications |

|---|---|---|

| Direct Heating | High efficiency, risk of contamination | Mineral processing, waste treatment |

| Indirect Heating | High purity, prevents contamination | Pharmaceuticals, electronics, advanced materials |

| Parallel Flow | Gentle heating, uniform temperature | Drying, sensitive materials |

| Opposing Flow | High thermal efficiency, maximum temperature | Calcination, reduction, chemical reactions |

| Batch Mode | Discrete loads, precise control | Laboratory R&D, pilot-scale testing |

| Continuous Mode | Uninterrupted production, high throughput | Industrial manufacturing, bulk processing |

Unlock Precision and Efficiency with KINTEK's Advanced Rotary Tube Furnaces

Are you struggling to balance purity, efficiency, and scalability in your thermal processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Whether you're in R&D requiring high-purity batch processing or industrial production demanding continuous throughput, KINTEK delivers reliable, optimized solutions. Don't let design complexities hold you back—contact us today to discuss how our furnaces can enhance your process efficiency and achieve superior results!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- In what environments are rotary tube furnaces considered indispensable? Essential for Uniform Thermal Processing

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- How is the Rotary Tube Tilt Furnace used in the carbon activation process? Achieve Uniform, High-Porosity Activated Carbon

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency