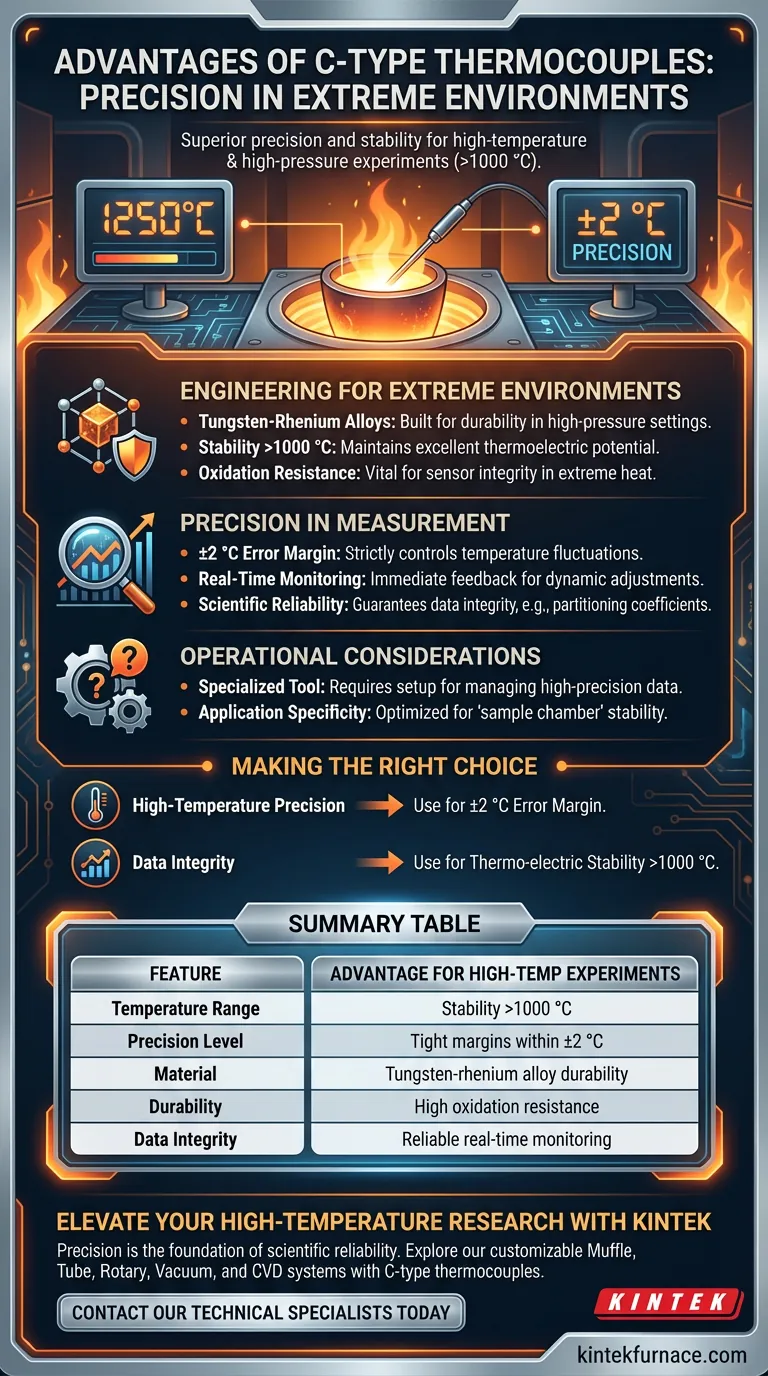

The C-type thermocouple offers superior precision and stability for experiments conducted in extreme environments. Specifically, it provides reliable real-time temperature monitoring in conditions exceeding 1000 °C, ensuring that thermal fluctuations are kept within a tight error margin to guarantee data integrity.

The defining advantage of the C-type (tungsten-rhenium) thermocouple is its excellent thermoelectric potential stability. This characteristic allows researchers to control temperatures with ±2 °C precision, which is critical for the scientific reliability of partitioning coefficient measurements.

Engineering for Extreme Environments

Composition and Durability

The C-type thermocouple is constructed from tungsten-rhenium alloys. This material composition is specifically selected to withstand the rigors of high-temperature and high-pressure experimentation.

Stability at Temperatures Exceeding 1000 °C

Standard sensors often degrade or drift when pushed beyond certain thermal limits. The C-type thermocouple maintains excellent thermoelectric potential stability even in environments that exceed 1000 °C.

Resistance to Oxidation

In addition to thermal stability, this specific thermocouple type exhibits oxidation resistance in these extremely high-temperature settings. This resistance is vital for maintaining the sensor's physical integrity and calibration over the duration of an experiment.

Precision in Measurement

Minimizing Error Margins

For sensitive scientific measurements, temperature control is paramount. The C-type thermocouple ensures that temperature fluctuations are strictly controlled within an error margin of ±2 °C.

Real-Time Monitoring Capabilities

This tool allows for precise, real-time monitoring of conditions within the sample chamber. Immediate feedback on temperature changes allows for dynamic adjustments to maintain experimental conditions.

Ensuring Scientific Reliability

The ultimate goal of using such a precise instrument is valid data. By stabilizing the environment, the C-type thermocouple guarantees the reliability of complex metrics, such as partitioning coefficient measurements.

Operational Considerations

The Cost of Precision

While the C-type thermocouple provides exceptional accuracy, it is a specialized tool. Relying on this level of precision requires a setup capable of interpreting and managing the data to maintain the ±2 °C standard.

Application Specificity

This thermocouple is optimized for "sample chamber" environments where potential stability is the priority. It is most effective when the experiment demands high scientific rigor regarding thermal fluctuations.

Making the Right Choice for Your Experiment

To determine if the C-type thermocouple is the correct sensor for your specific application, consider your tolerance for error and your environmental baselines.

- If your primary focus is High-Temperature Precision: Use this thermocouple to ensure temperature fluctuations remain strictly within the ±2 °C error margin.

- If your primary focus is Data Integrity: Rely on the C-type's thermoelectric stability to validate partitioning coefficient measurements in environments over 1000 °C.

By selecting a sensor with high potential stability and oxidation resistance, you transform temperature from a variable of uncertainty into a controlled constant.

Summary Table:

| Feature | Advantage for High-Temp Experiments |

|---|---|

| Temperature Range | Excellent stability in environments exceeding 1000 °C |

| Precision Level | Maintains tight error margins within ±2 °C |

| Material | Tungsten-rhenium alloy for superior durability |

| Durability | High resistance to oxidation in extreme conditions |

| Data Integrity | Reliable real-time monitoring for partitioning measurements |

Elevate Your High-Temperature Research with KINTEK

Precision is the foundation of scientific reliability. Whether you are conducting complex partitioning coefficient measurements or high-pressure material synthesis, KINTEK provides the advanced thermal solutions you need.

Backed by expert R&D and manufacturing, we offer a comprehensive range of lab high-temp systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which can be customized with high-precision C-type thermocouples to meet your unique experimental needs.

Don't let thermal fluctuations compromise your data. Contact our technical specialists today to discover how our customizable furnaces can transform your laboratory efficiency and ensure absolute control over your thermal environment.

Visual Guide

References

- Wanying Wang, Yuan Li. Redox control of the partitioning of platinum and palladium into magmatic sulfide liquids. DOI: 10.1038/s43247-024-01366-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the properties and handling requirements of ceramic sheath materials? Master High-Temp and Insulation Challenges

- What are some industrial applications of SiC heating elements? Boost Efficiency in High-Temp Processes

- How do MoSi2 heating elements resist oxidation? Unlock the Secret to High-Temperature Durability

- What is the importance of using B-type thermocouples in directional solidification? Ensure 1500°C+ Thermal Accuracy

- How do SC Type Silicon Carbide Heating Elements contribute to powder metallurgy? Achieve Uniform Sintering for Dense Parts

- What are the key benefits of molybdenum heating elements? Unlock Extreme-Temperature Reliability

- How do alumina ceramic tubes improve temperature control and safety in high-temperature furnaces? Enhance Precision and Safety Up to 1800°C

- What are the key advantages of Silicon Carbide heating elements? Unlock High-Temp Reliability and Efficiency