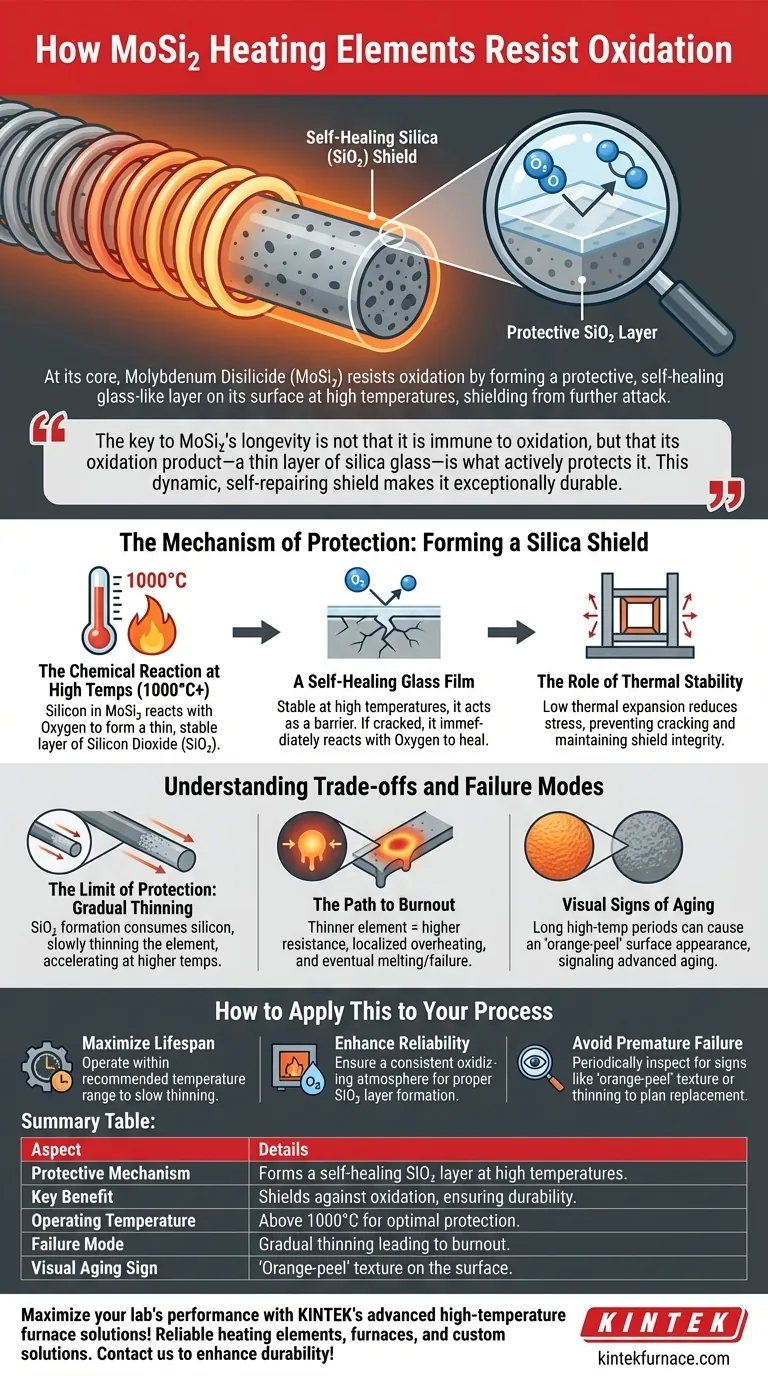

At its core, Molybdenum Disilicide (MoSi₂) resists oxidation by forming a protective, self-healing glass-like layer on its surface at high temperatures. This passive film of silicon dioxide (SiO₂) acts as a physical and chemical barrier, shielding the underlying material from further attack by oxygen.

The key to MoSi₂'s longevity is not that it is immune to oxidation, but that its oxidation product—a thin layer of silica glass—is what actively protects it. This dynamic, self-repairing shield is what makes the material exceptionally durable in high-temperature oxidizing environments.

The Mechanism of Protection: Forming a Silica Shield

To understand the resilience of MoSi₂ elements, you must understand the nature of the protective layer that forms when they are first heated. This isn't a coating applied during manufacturing; it's a reaction that happens in place.

The Chemical Reaction at High Temperatures

When a MoSi₂ element is heated above approximately 1000°C in an atmosphere containing oxygen, the silicon within the material preferentially reacts with the oxygen. This forms a thin, non-porous, and highly stable layer of silicon dioxide (SiO₂), also known as silica.

A Self-Healing Glass Film

This SiO₂ layer is essentially a type of glass. It is incredibly stable at high temperatures and acts as a barrier, preventing oxygen from reaching the fresh MoSi₂ material underneath.

Crucially, this layer is self-healing. If a thermal shock or mechanical stress causes a microscopic crack in the silica film, the newly exposed MoSi₂ will immediately react with oxygen to "heal" the breach, reforming the protective layer.

The Role of Thermal Stability

MoSi₂ also has a very low coefficient of thermal expansion. This means it expands and contracts very little during heating and cooling cycles, reducing the mechanical stress on the element and its protective SiO₂ layer. This stability helps prevent cracking and maintains the integrity of the shield.

Understanding the Trade-offs and Failure Modes

No material is indestructible. The same mechanism that protects the element also contributes to its eventual failure, a process that is critical to understand for maintenance and operational planning.

The Limit of Protection: Gradual Thinning

While the SiO₂ layer is protective, its formation consumes silicon from the element. This process occurs very slowly over the element's life, causing a gradual thinning of the element's cross-section. The rate of this oxidation loss accelerates at higher operating temperatures.

The Path to Burnout

As the element becomes thinner, its electrical resistance in that area increases. This localized increase in resistance causes a corresponding increase in power density, leading to localized overheating. Eventually, a spot will become so thin and hot that it melts, causing the element to fail.

Visual Signs of Aging

Over long periods at very high temperatures, changes in the material's grain structure can occur. This can sometimes give the surface a distinct "orange-peel" appearance, which is a visual indicator of an aging element that may be approaching the end of its operational life.

How to Apply This to Your Process

Understanding this protective mechanism is key to maximizing the lifespan and reliability of your furnace elements. The operational environment is just as important as the material itself.

- If your primary focus is maximum lifespan: Operate the elements within their recommended temperature range. Pushing them to their absolute limit will significantly accelerate the rate of oxidation and thinning.

- If your primary focus is reliability: Ensure a consistently oxidizing atmosphere is present during high-temperature operation. This oxygen is required for the SiO₂ layer to form and self-heal properly.

- If your primary focus is avoiding premature failure: Periodically inspect elements for signs of advanced aging, such as the "orange-peel" texture or visible thinning, to proactively plan for replacement.

By managing the operational conditions, you are directly managing the health of the element's protective silica shield.

Summary Table:

| Aspect | Details |

|---|---|

| Protective Mechanism | Forms a self-healing SiO₂ layer at high temperatures |

| Key Benefit | Shields against oxidation, ensuring durability |

| Operating Temperature | Above 1000°C for optimal protection |

| Failure Mode | Gradual thinning leading to burnout |

| Visual Aging Sign | 'Orange-peel' texture on the surface |

Maximize your lab's performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable heating elements and furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance durability and efficiency in your processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance