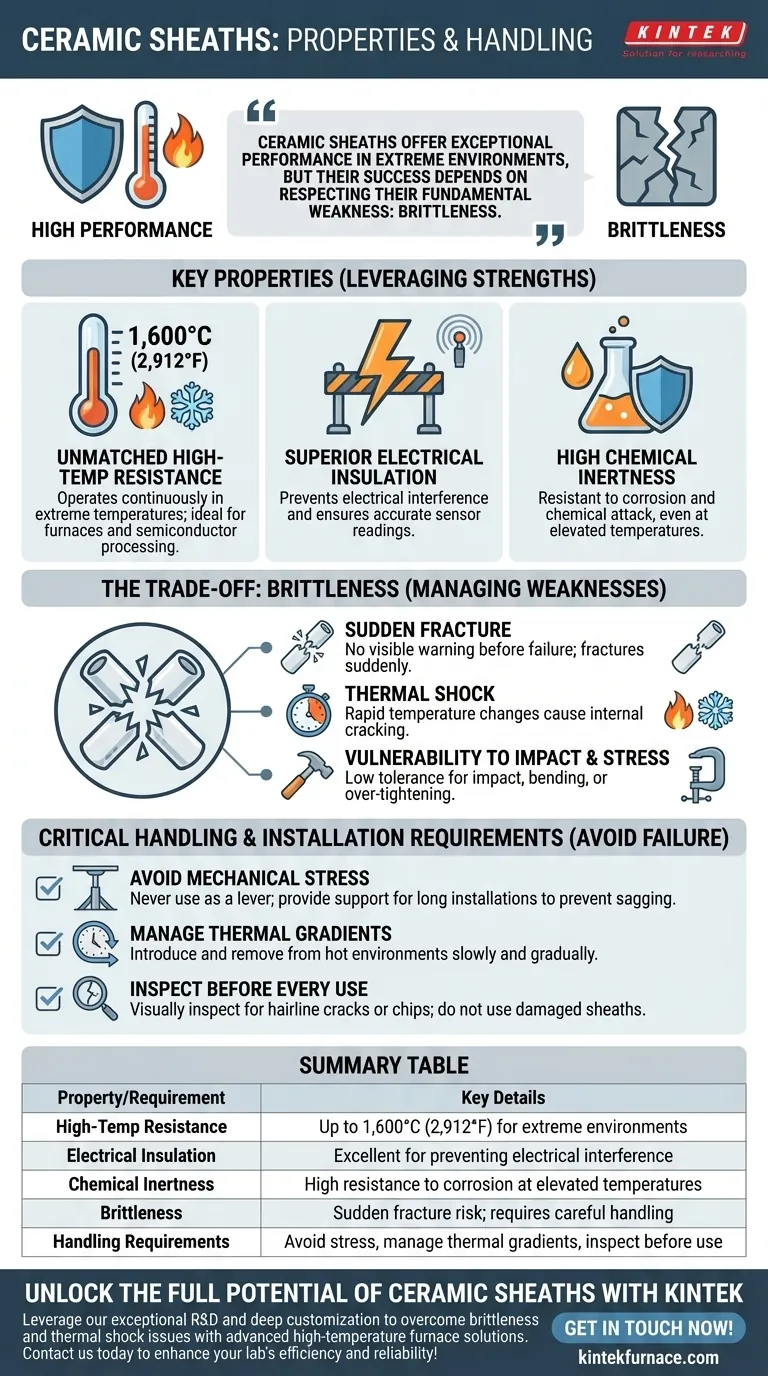

At their core, ceramic sheath materials are defined by a powerful duality. They offer exceptional performance in extreme environments, specifically with high-temperature resistance up to 1,600°C and superb electrical insulation. However, this high performance is coupled with significant brittleness, which dictates every aspect of their handling and application.

Ceramic sheaths are selected for applications where metal alloys would fail from heat or cause electrical interference. Success with these materials is not just about leveraging their strengths but fundamentally about respecting their primary weakness: a complete lack of ductility.

Key Properties of Ceramic Sheaths

The decision to use a ceramic sheath is almost always driven by its ability to survive conditions that are hostile to other materials.

Unmatched High-Temperature Resistance

Ceramic sheaths can operate continuously in environments up to 1,600°C (2,912°F), far beyond the melting point of most industrial metals. This makes them essential for applications like industrial furnaces, kilns, and semiconductor processing.

Superior Electrical Insulation

Unlike metals, ceramics are excellent electrical insulators. This property is critical when the sheath is protecting a sensor, like a thermocouple, from electrical noise or short-circuiting, ensuring accurate measurements in high-temperature, electrically active environments.

High Chemical Inertness

Ceramics are generally very resistant to corrosion and chemical attack, even at elevated temperatures. This allows them to be used in aggressive atmospheres that would quickly degrade metal sheaths.

Understanding the Trade-off: Brittleness

The primary challenge of working with ceramics is their inherent brittleness. This single property has significant practical implications that must be managed carefully.

What "Brittle" Means in Practice

Unlike a metal tube that will bend or deform when stressed, a ceramic sheath will fracture suddenly and completely. There is no visible warning before failure.

Susceptibility to Thermal Shock

Rapid changes in temperature create internal stresses that can easily crack the material. Plunging a cool ceramic sheath into a hot furnace is a common cause of immediate failure. This phenomenon is known as thermal shock.

Vulnerability to Mechanical Impact and Stress

Ceramic sheaths have very low tolerance for impact or bending forces. Dropping the material, striking it against a hard surface, or even over-tightening a compression fitting can cause it to shatter.

Critical Handling and Installation Requirements

Proper handling is not just a best practice; it is a fundamental requirement for the successful use of ceramic sheaths. Failure to follow these protocols will almost certainly result in breakage.

Avoid All Mechanical Stress

Never use the sheath as a lever or support. For long, horizontal installations, the sheath must be supported along its length to prevent it from sagging and breaking under its own weight.

Manage Thermal Gradients

Always introduce ceramic sheaths into hot environments slowly and gradually. This allows the material to heat up uniformly, minimizing the internal stress caused by thermal expansion. The same principle applies to cooling.

Inspect Before Every Use

Before installation, carefully perform a visual inspection of the entire sheath. Look for any hairline cracks or chips, as these are stress points where a fracture is likely to begin. Do not use a damaged sheath.

Making the Right Choice for Your Application

Use these guidelines to determine if a ceramic sheath is the correct choice for your specific goal.

- If your primary focus is extreme temperature stability (above 1200°C): Ceramic is often the only viable choice, but you must design your process and handling protocols around its fragility.

- If your primary focus is durability against vibration or impact: A high-temperature metal alloy sheath is a much safer and more reliable option, provided it meets your temperature needs.

- If you need both high-temperature performance and electrical insulation: Ceramic is the superior technical solution, but success is entirely dependent on meticulous handling.

Ultimately, choosing ceramic is a deliberate engineering decision to trade mechanical robustness for unparalleled thermal and electrical performance.

Summary Table:

| Property/Requirement | Key Details |

|---|---|

| High-Temperature Resistance | Up to 1,600°C (2,912°F) for extreme environments |

| Electrical Insulation | Excellent for preventing electrical interference and ensuring accurate sensor readings |

| Chemical Inertness | High resistance to corrosion and chemical attack at elevated temperatures |

| Brittleness | Sudden fracture risk; handle with care to avoid mechanical stress and thermal shock |

| Handling Requirements | Avoid mechanical stress, manage thermal gradients, and inspect for cracks before use |

Unlock the Full Potential of Ceramic Sheaths with KINTEK

Struggling with high-temperature applications or electrical insulation challenges? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, helping you overcome brittleness and thermal shock issues with tailored ceramic sheath materials.

Contact us today to discuss how our expertise can enhance your lab's efficiency and reliability—Get in touch now!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision