At its core, Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) offers significant advantages over traditional CVD methods primarily through its ability to generate a clean, high-density plasma. This results in films of superior purity and quality, especially for demanding materials like diamond, while providing exceptional process control and stability.

The fundamental choice between MPCVD and other methods is not about which is universally "better," but which provides the right environment for your specific goal. MPCVD excels by creating an intensely reactive, contaminant-free plasma, making it the leading choice for high-performance crystalline films, though this same intensity introduces specific limitations.

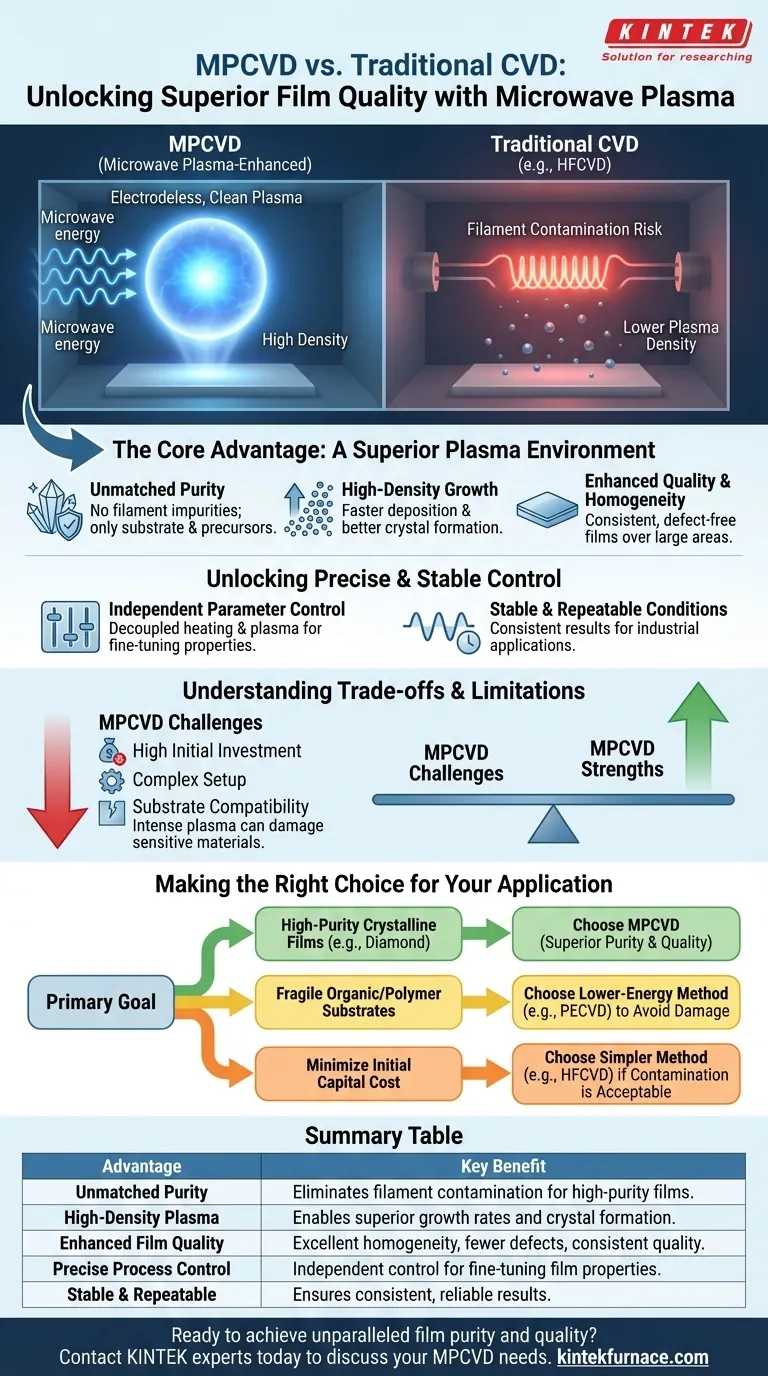

The Core Advantage: A Superior Plasma Environment

The primary distinction of MPCVD lies in how it generates and utilizes plasma. Unlike methods that rely on thermal energy or direct electrical contact, MPCVD uses microwaves to create a contained, electrodeless plasma discharge.

Unmatched Purity by Design

Traditional Hot Filament CVD (HFCVD) methods are susceptible to contamination, as the hot metal filaments can degrade and introduce impurities into the film. MPCVD completely avoids this problem. Its electrodeless microwave-powered plasma ensures that the only materials in the chamber are the substrate and the precursor gases, leading to exceptionally high-purity films.

High-Density Plasma for Superior Growth

MPCVD is uniquely effective at creating a high density of charged particles and reactive species. The ionization degree of the gas can exceed 10%, creating a supersaturated environment of atomic hydrogen and carbon-containing radicals. This highly energetic and dense plasma is the engine behind MPCVD's superior performance, enabling higher deposition rates and better crystal formation compared to other plasma-based techniques.

The Result: Enhanced Film Quality and Homogeneity

This clean, dense plasma directly translates to superior output. MPCVD systems are known for producing films with excellent homogeneity over large areas. The stable plasma conditions ensure that the growth is uniform, resulting in consistent sample quality, fewer defects, and superior crystalline structure.

Unlocking Precise and Stable Control

The indirect nature of plasma generation in MPCVD provides process engineers with a greater degree of control over the deposition environment.

Independent Control of Key Parameters

Because the plasma is generated by microwaves, there is a decoupling of the plasma generation from the substrate heating. This allows for more precise and independent control of reaction temperature, plasma density, and gas composition, enabling fine-tuning of the film's properties like thickness and crystal quality.

Stable and Repeatable Conditions

MPCVD systems are capable of generating a large, stable discharge plasma area. This stability is critical for industrial applications, as it ensures that deposition conditions remain constant over long periods, leading to highly repeatable results and consistent quality from one batch to the next.

Understanding the Trade-offs and Limitations

No technology is without its compromises. The high-performance nature of MPCVD comes with specific challenges that must be considered.

High Initial Investment and Complexity

The primary drawback of MPCVD is its complex and expensive setup. The need for a microwave generator, a resonant cavity, waveguides, and sophisticated control systems results in a significantly higher initial capital cost compared to simpler methods like HFCVD.

Substrate Compatibility Concerns

The very high-energy plasma that makes MPCVD so effective can also be a limitation. This intense plasma can damage certain sensitive substrates, such as organic materials or some polymers. While the bulk substrate temperature can be kept relatively low, the direct plasma interaction can be too aggressive for fragile materials.

Making the Right Choice for Your Application

Selecting the correct CVD method requires aligning the technology's strengths with your primary objective.

- If your primary focus is high-purity, high-quality crystalline films (like diamond): MPCVD is the superior choice due to its clean, contaminant-free, and high-density plasma environment.

- If your primary focus is depositing on fragile organic or polymer substrates: A lower-energy method like a standard Parallel Plate PECVD system may be more suitable to avoid plasma-induced damage.

- If your primary focus is minimizing initial capital cost for general film deposition: Simpler methods like Hot Filament CVD (HFCVD) can be a viable starting point, provided you can tolerate the inherent risk of filament contamination.

Ultimately, choosing MPCVD is a strategic decision to prioritize film purity and crystalline quality above all else.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unmatched Purity | Electrodeless plasma eliminates filament contamination for high-purity films. |

| High-Density Plasma | Enables superior growth rates and crystal formation for materials like diamond. |

| Enhanced Film Quality | Produces films with excellent homogeneity, fewer defects, and consistent quality. |

| Precise Process Control | Independent control of temperature and plasma density for fine-tuning film properties. |

| Stable & Repeatable | Large, stable plasma ensures consistent, reliable results for industrial applications. |

Ready to achieve unparalleled film purity and quality in your lab?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced MPCVD solutions tailored to your unique experimental requirements. Our expertise in high-temperature furnace systems, including our deep customization capabilities, ensures you get the precise control and performance needed for cutting-edge materials research.

Contact our experts today to discuss how our MPCVD technology can advance your specific application.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production