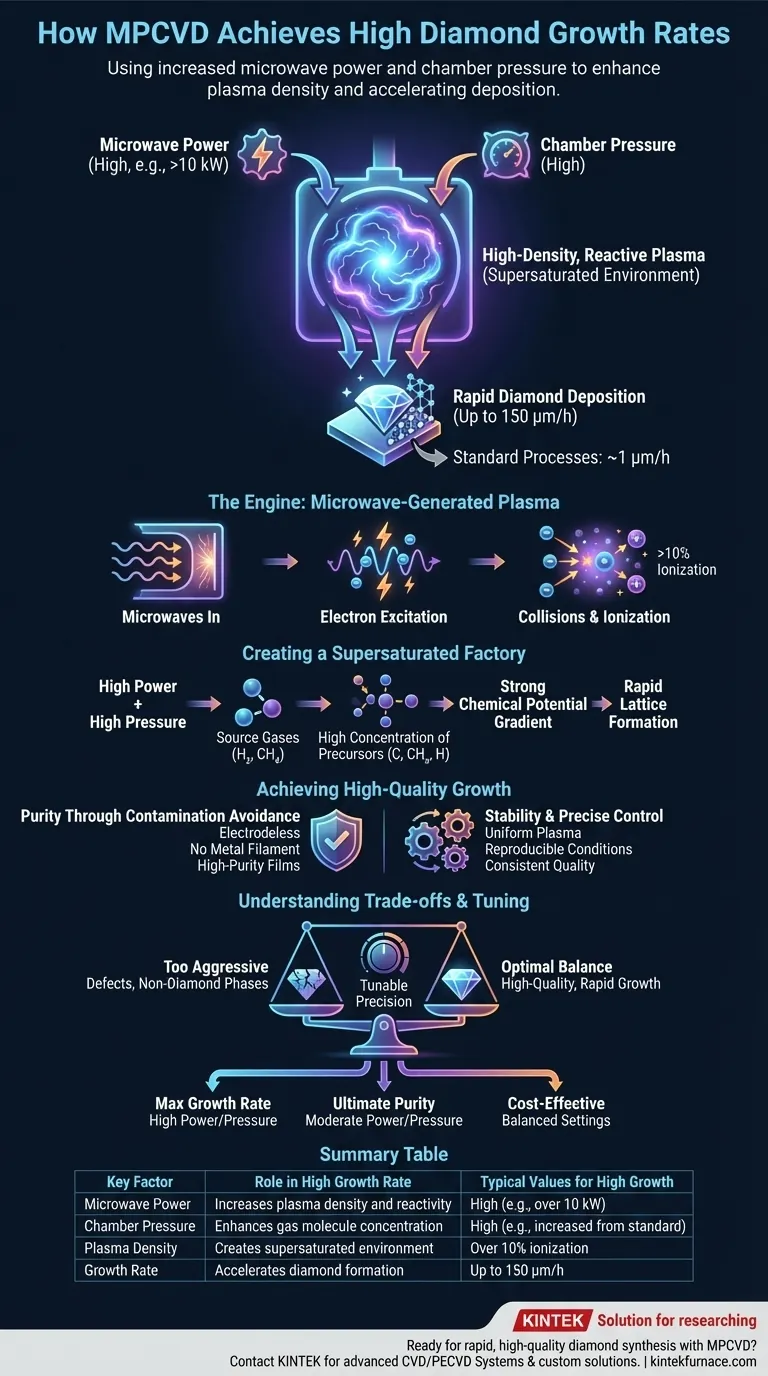

At its core, the Microwave Plasma Chemical Vapor Deposition (MPCVD) method achieves exceptionally high diamond growth rates by using increased microwave power and chamber pressure. This strategy dramatically enhances the density and reactivity of the plasma used for synthesis, accelerating the deposition of carbon atoms onto the diamond substrate at rates up to 150 μm/h, far exceeding the typical 1 μm/h of standard processes.

The fundamental advantage of MPCVD is not just speed, but controlled efficiency. It excels by using microwave energy to create an extremely dense, pure, and stable plasma—a highly reactive environment that is "supersaturated" with the specific atomic building blocks needed for rapid, high-quality diamond formation.

The Engine of Growth: The Microwave-Generated Plasma

The key to MPCVD's performance lies in how it generates and maintains its plasma. This process is fundamentally different and more efficient than older methods like Hot Filament CVD (HFCVD).

How Microwaves Create Plasma

In an MPCVD chamber, microwave energy is introduced into a resonant cavity containing a mixture of gases, typically hydrogen and a carbon source like methane. This energy excites free electrons, causing them to oscillate violently.

These oscillating electrons collide with gas atoms and molecules, stripping them of their own electrons. This cascade of collisions creates a self-sustaining, ionized gas cloud known as a plasma.

The Role of High Power and Pressure

To accelerate diamond growth, two parameters are critical: microwave power and gas pressure. Increasing the input microwave power drives more energetic collisions, leading to a higher degree of gas ionization—over 10% in high-growth-rate systems.

Simultaneously, increasing the chamber pressure packs more gas molecules into the same space. The combination of high power and high pressure produces a high-density plasma rich in reactive atomic species.

Creating a "Supersaturated" Environment

This dense plasma becomes a highly efficient factory for producing the building blocks of diamond. The intense conditions break down the source gases into a high concentration of carbon-containing atomic groups and atomic hydrogen.

The chamber becomes supersaturated with these precursors. This state creates a strong chemical potential gradient, driving the carbon species to deposit rapidly onto the substrate and form the diamond lattice.

Why MPCVD Enables High-Quality Growth

Speed is only useful if the resulting diamond is of high quality. MPCVD's design incorporates several advantages that ensure purity and structural integrity, even at high growth rates.

Purity Through Contamination Avoidance

Unlike HFCVD, which uses a hot metal filament that can degrade and release impurities into the chamber, MPCVD is an electrodeless process. The plasma is generated by external microwaves, eliminating this major source of contamination and resulting in high-purity diamond films.

Stability and Precise Control

MPCVD systems offer exceptionally stable and controllable reaction conditions. The temperature can be precisely managed, and the plasma itself is large and uniform. This stability ensures that the growth is reproducible and the resulting diamond quality is consistent across the entire substrate.

Understanding the Trade-offs

While MPCVD is a superior technique, achieving its maximum potential requires balancing competing factors.

The Power-Quality Balance

Simply increasing power and pressure to their maximums does not guarantee success. An overly aggressive process can lead to the formation of non-diamond carbon phases or crystal defects, compromising the quality of the final product. The key is to find the optimal balance that maximizes the growth rate of high-quality diamond.

System Complexity and Cost

The sophistication that enables MPCVD's performance also adds to its complexity and initial cost. The equipment for generating and controlling microwave plasma is more advanced and expensive than simpler setups like HFCVD, representing a significant upfront investment.

Making the Right Choice for Your Synthesis Goal

The optimal MPCVD parameters depend entirely on your end objective.

- If your primary focus is maximum growth rate: You will operate at higher microwave power and chamber pressures, pushing the limits of supersaturation while carefully monitoring for the onset of defects.

- If your primary focus is ultimate purity and crystalline perfection: You will likely use more moderate power and pressure settings, prioritizing stable, controlled growth over raw speed to minimize defect formation.

- If your primary focus is cost-effective coating: You will tune the process for a balance of reasonable speed, acceptable quality, and efficient gas and power usage to optimize operational costs.

Ultimately, the power of MPCVD lies in its tunable precision, allowing you to engineer the synthesis environment to meet your specific goals.

Summary Table:

| Key Factor | Role in High Growth Rate | Typical Values for High Growth |

|---|---|---|

| Microwave Power | Increases plasma density and reactivity | High (e.g., over 10 kW) |

| Chamber Pressure | Enhances gas molecule concentration | High (e.g., increased from standard) |

| Plasma Density | Creates supersaturated environment for rapid deposition | Over 10% ionization |

| Growth Rate | Accelerates diamond formation | Up to 150 μm/h |

Ready to achieve rapid, high-quality diamond synthesis with MPCVD? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including our specialized CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for diamond growth. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems