In the ceramic and electronic component industries, Molybdenum Disilicide (MoSi2) heating elements are specifically used for the high-temperature firing and sintering of critical materials. Key applications include the manufacturing of ferrites, varistors, thermistors, titanites, magnets, advanced refractories, insulators, and semiconductor materials.

The core challenge in producing advanced ceramics and electronics is achieving precise, extremely high temperatures without introducing contaminants. MoSi2 elements are the solution because they operate reliably up to 1800°C and form a self-healing protective layer that prevents oxidation and ensures product purity.

Why MoSi2 Dominates High-Temperature Processing

The adoption of MoSi2 elements is not arbitrary; it is a direct solution to the extreme demands of modern material science. Their unique properties enable processes that are impossible with other heating technologies.

Reaching Extreme Operating Temperatures

MoSi2 elements are engineered to function in industrial furnaces at temperatures between 1200°C and 1800°C (2192°F to 3272°F).

This temperature range is essential for the sintering and densification of advanced ceramics, where material powders are fused into a solid, durable state.

Unmatched Resistance to Oxidation

At high temperatures, MoSi2 reacts with oxygen to form a thin, non-porous layer of silica (glass) on its surface.

This protective layer is self-healing and prevents the underlying element from degrading. This ensures a long service life and, more importantly, prevents element material from contaminating the product being fired.

Enabling Process Control and Uniformity

The consistent performance of MoSi2 allows for highly uniform heating zones within a furnace.

This precision is critical when firing electronic components like thermistors or varistors, where even minor temperature deviations can dramatically alter the final electrical properties and yield.

Key Applications in Component Manufacturing

While the principle is consistent—providing clean, high heat—the specific goals vary depending on the component being produced.

Firing of Passive Electronic Components

Components like ferrites, varistors, and titanites derive their specific magnetic or electrical characteristics from their crystalline structure.

The firing process, enabled by MoSi2 elements, is what sets this final structure. It requires a controlled thermal profile in a clean atmosphere to achieve the desired performance specifications.

Sintering of Advanced and Structural Ceramics

Materials such as high-purity refractories, insulators, and grinding wheels require sintering at extreme temperatures to achieve maximum density and strength.

MoSi2 furnaces provide the necessary energy to bond ceramic particles tightly, creating robust components capable of withstanding severe mechanical or thermal stress.

Processing of Magnetic and Semiconductor Materials

The manufacturing of specialized magnets and semiconductor materials often requires heat treatment in carefully controlled atmospheres.

The inert nature of the MoSi2 element's protective silica layer makes it ideal for these applications, minimizing the risk of reactions that could compromise material purity.

Understanding the Trade-offs

No technology is without limitations. Objectively evaluating MoSi2 requires understanding its specific challenges.

Brittleness at Room Temperature

MoSi2 elements are ceramic-based and are extremely brittle at lower temperatures. They require careful handling and installation to prevent fracture.

Furnace design must also account for this, ensuring elements are not subjected to mechanical stress, especially during heat-up and cool-down cycles.

Susceptibility to "Pest" Oxidation

In a lower temperature range of approximately 400°C to 700°C, MoSi2 can undergo an accelerated form of oxidation known as "pesting," which can cause it to disintegrate.

Because of this, furnaces using these elements are designed to move through this temperature range as quickly as possible. They are not suitable for low-temperature holding applications.

Higher Initial Cost

Compared to elements like nichrome or even silicon carbide (SiC), MoSi2 heating elements represent a higher initial investment.

This cost is justified by their superior temperature capability and long life in demanding, high-temperature oxidizing environments where other elements would fail rapidly.

Making the Right Choice for Your Goal

Your process requirements will determine if MoSi2 is the correct technology for your application.

- If your primary focus is producing advanced electronics or ceramics at temperatures above 1600°C: MoSi2 is the industry standard, offering unmatched stability and resistance to contamination.

- If your process requires frequent cycling or involves potential for mechanical shock: The inherent brittleness of MoSi2 must be a central design consideration for your furnace and handling procedures.

- If your application operates below 1400°C and cost is a primary driver: It is worth evaluating alternatives like Silicon Carbide (SiC) elements, which provide a different balance of performance, durability, and cost.

Ultimately, choosing MoSi2 is a strategic decision to enable state-of-the-art material processing where temperature and purity are non-negotiable.

Summary Table:

| Application | Key Benefits | Temperature Range |

|---|---|---|

| Firing of Passive Electronic Components (e.g., ferrites, varistors) | Precise temperature control, uniform heating, prevents contamination | 1200°C to 1800°C |

| Sintering of Advanced Ceramics (e.g., refractories, insulators) | High density and strength, reliable performance in oxidizing atmospheres | 1200°C to 1800°C |

| Processing of Magnetic and Semiconductor Materials | Maintains material purity, ideal for controlled atmospheres | 1200°C to 1800°C |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for ceramics and electronics, delivering superior purity, temperature control, and efficiency. Contact us today to discuss how we can optimize your high-temperature processes and achieve your material science goals!

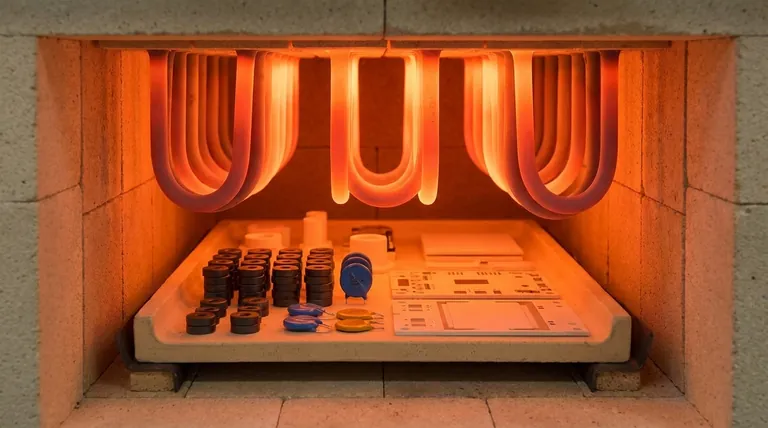

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C