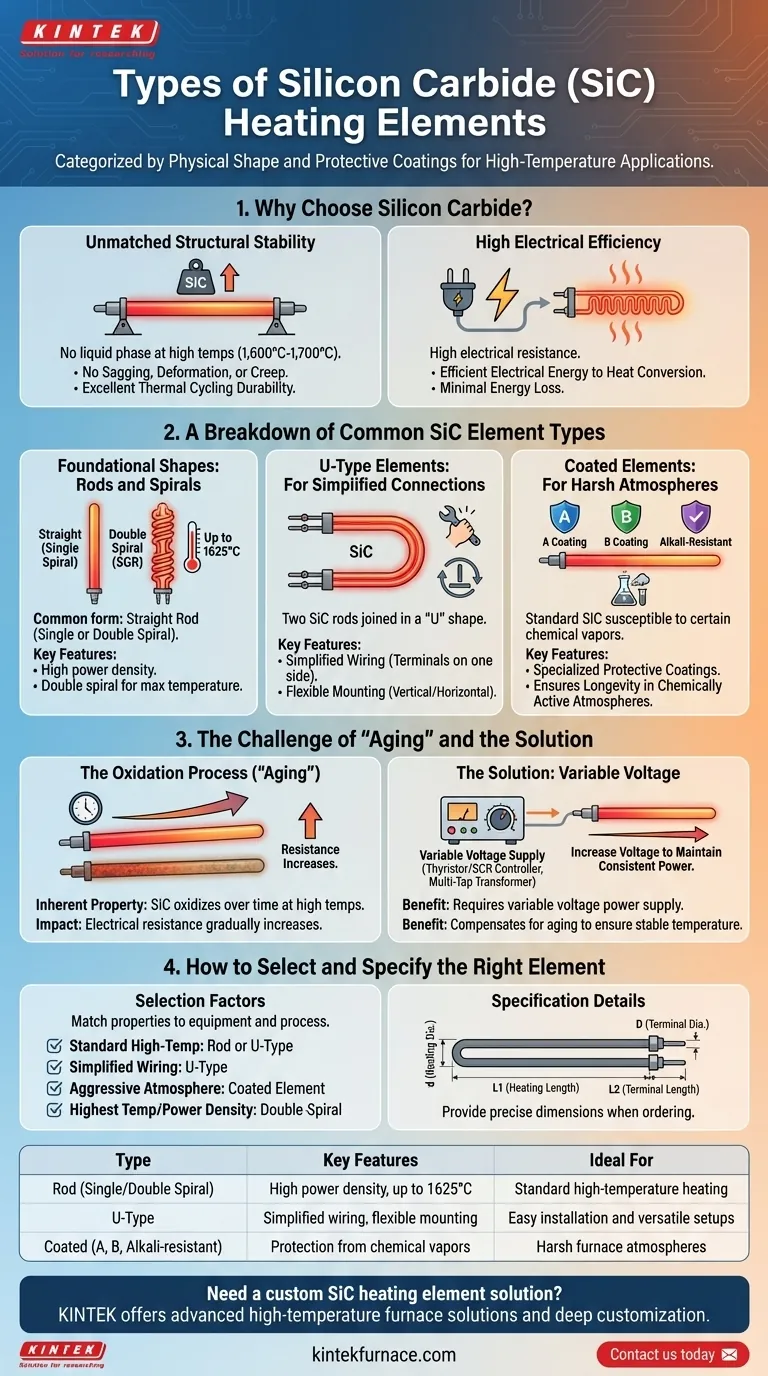

In short, silicon carbide (SiC) heating elements are categorized by their physical shape and the presence of protective coatings. Common shapes include straight rods (single or double spiral), U-type, and multi-leg elements, while specialized coatings are applied to protect the element from chemical attack in specific furnace atmospheres.

The specific type of SiC element you need is defined by two factors: the physical mounting requirements of your furnace and the chemical environment it will operate in. While all SiC elements offer exceptional high-temperature performance, their longevity depends on managing a gradual aging process.

Why Choose Silicon Carbide?

Silicon carbide is a premier material for electric heating elements operating at extreme temperatures, often between 1,600°C and 1,700°C. Its primary advantages are rooted in its fundamental physical properties.

Unmatched Structural Stability

Unlike many metallic elements, SiC has no liquid phase. This means it will not sag, deform, or creep under its own weight at high temperatures, ensuring long-term structural integrity.

This high rigidity and low thermal expansion make it exceptionally durable in applications involving rapid thermal cycling.

High Electrical Efficiency

SiC elements possess a high electrical resistance. This property is key to their function, as it allows them to efficiently convert electrical energy directly into heat with minimal loss.

A Breakdown of Common SiC Element Types

While there are many variations, SiC elements can be grouped into categories based on their physical shape and the application of protective surface coatings.

Foundational Shapes: Rods and Spirals

The most common form is a straight rod-type element. These can be manufactured with a single spiral or a double spiral heating section.

The double spiral design, such as an SGR type, often allows for higher power density and can achieve maximum temperatures up to 1625°C.

U-Type Elements: For Simplified Connections

A U-type element consists of two SiC rods joined at one end, creating a "U" shape with both electrical terminals on the same side.

This design simplifies wiring and is highly versatile, as it can be mounted either vertically or horizontally to suit the furnace design.

Coated Elements: For Harsh Atmospheres

Standard SiC can be susceptible to damage from certain chemical vapors. To counteract this, manufacturers offer elements with specialized protective coatings.

Common examples include A coating, B coating, or alkali-resistant coatings. Selecting the correct coating is critical for ensuring element longevity in furnaces with chemically active atmospheres.

Understanding the Trade-offs: The Challenge of "Aging"

The primary operational consideration for SiC elements is a phenomenon known as aging. This is not a defect but an inherent property of the material.

The Oxidation Process

Over time and at high temperatures, the silicon carbide gradually oxidizes. This process slowly increases the element's electrical resistance.

To maintain a consistent power output (and therefore a stable temperature), the voltage supplied to the element must be gradually increased over its service life.

The Need for Variable Voltage

Because of aging, SiC heating systems require a variable voltage power supply, such as a thyristor (SCR) controller or a multi-tap transformer. A fixed voltage system will result in diminishing heat output as the element ages.

How to Select and Specify the Right Element

Choosing the correct element is a matter of matching its properties to your equipment and process. When ordering, you must provide precise dimensions, typically including the heating section diameter (d), terminal section diameter (D), heating section length (L1), and terminal section length (L2).

- If your primary focus is standard high-temperature heating: A straight rod or U-type element is the most common and cost-effective choice.

- If your primary focus is simplified wiring or flexible mounting: A U-type element is ideal, as it places both connections on one side.

- If your primary focus is operation in a chemically aggressive atmosphere: You must select an element with a protective coating designed to resist your specific process vapors.

- If your primary focus is achieving the highest possible temperature and power density: A specialized double-spiral element may be required.

Understanding these distinctions ensures you select an element that delivers both high performance and maximum operational life.

Summary Table:

| Type | Key Features | Ideal For |

|---|---|---|

| Rod (Single/Double Spiral) | High power density, up to 1625°C | Standard high-temperature heating |

| U-Type | Simplified wiring, flexible mounting | Easy installation and versatile setups |

| Coated (e.g., A, B, Alkali-resistant) | Protection from chemical vapors | Harsh furnace atmospheres |

Need a custom SiC heating element solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency with tailored SiC elements!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism