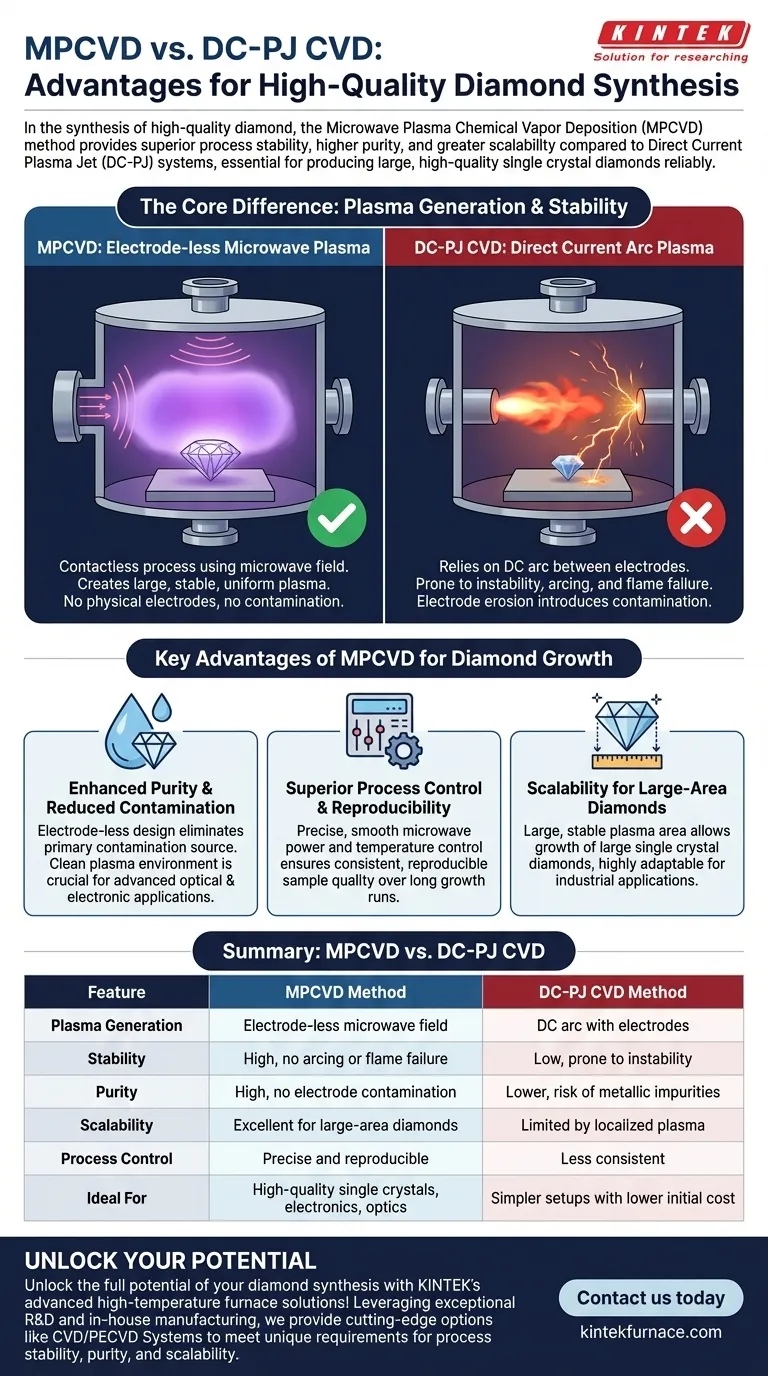

In the synthesis of high-quality diamond, the MPCVD method holds several distinct advantages over DC-PJ CVD. Specifically, Microwave Plasma Chemical Vapor Deposition (MPCVD) provides superior process stability, higher purity, and greater scalability by avoiding the inherent instabilities, such as arcing and flame failure, that are common in Direct Current Plasma Jet (DC-PJ) systems. This stability is critical for producing large, high-quality single crystal diamonds reliably.

The core difference lies in how plasma is generated. MPCVD uses an electrode-less microwave field to create a large, stable, and pure plasma, whereas DC-PJ CVD relies on a direct current arc that is prone to instability and can introduce contamination, directly impacting final diamond quality.

The Core Difference: Plasma Generation and Stability

The fundamental advantages of MPCVD stem from its method of generating and sustaining plasma, which stands in stark contrast to the mechanics of a DC-PJ system.

MPCVD: Electrode-less Microwave Plasma

MPCVD utilizes microwave energy to excite process gases into a plasma state. This process is contactless, meaning there are no physical electrodes within the reaction chamber.

This electrode-less design allows for the creation of a large, uniform, and exceptionally stable plasma area. This stability is crucial for consistent diamond growth over long periods.

DC-PJ CVD: Direct Current Arc Plasma

In contrast, the DC-PJ method generates plasma by creating an electric arc between two electrodes, which then shoots out as a "jet."

This reliance on a direct current arc introduces significant operational challenges. The process is susceptible to arcing and flame failure, which can cause abrupt changes in temperature and pressure.

Key Advantages of MPCVD for Diamond Growth

The stability and purity inherent to the MPCVD method translate into tangible benefits for producing high-quality diamond films and single crystals.

Enhanced Purity and Reduced Contamination

Because the MPCVD process is electrode-less, it eliminates a primary source of contamination. In DC systems, the electrodes can erode over time, introducing metallic impurities into the diamond.

The clean plasma environment in an MPCVD reactor is a key factor in achieving the high purity required for advanced optical and electronic applications.

Superior Process Control and Reproducibility

MPCVD systems allow for smooth and continuous adjustment of microwave power and precise, stable control over the reaction temperature.

This level of control ensures reproducible sample quality from one growth run to the next. DC-PJ systems, with their potential for arc instability, cannot offer the same degree of consistency.

Scalability for Large-Area Diamonds

The ability of MPCVD to generate a large and stable plasma area is essential for growing large-size single crystal diamonds.

The modular and scalable design of MPCVD technology makes it highly adaptable for industrial applications that require deposition on larger substrates, a significant advantage over the more localized DC plasma jet.

Understanding the Trade-offs and Limitations

While MPCVD is technologically superior for high-quality synthesis, it is important to understand the operational context and challenges associated with both methods.

The Problem of Arcing in DC-PJ CVD

The primary drawback of DC-PJ CVD is its instability. Sudden arcing or flame failure can cause thermal shock to the substrate.

This shock can cause crystal seeds to fall off the substrate, immediately terminating the growth run and destroying the product. This makes long, uninterrupted depositions extremely challenging.

Potential Complexity and Cost of MPCVD

MPCVD systems are sophisticated pieces of equipment. While described as cost-effective for high-quality production, the initial capital investment can be higher than for simpler DC-PJ setups.

The trade-off is clear: MPCVD requires a greater upfront investment for a process that delivers far superior stability, reproducibility, and ultimately, a higher-quality final product.

Making the Right Choice for Your Goal

Your choice of technology should be guided by your end-product requirements for quality, size, and purity.

- If your primary focus is producing large, high-purity single crystal diamonds: MPCVD is the superior choice due to its unparalleled process stability, control, and electrode-less design.

- If your primary focus is process reliability and long, uninterrupted growth runs: MPCVD's ability to avoid arcing and flame failure makes it far more dependable than DC-PJ CVD for consistent output.

- If you require the highest possible material quality for electronics or optics: The contamination-free environment of an MPCVD reactor is non-negotiable.

Understanding these fundamental differences in plasma generation empowers you to select the technology that best aligns with your objectives for quality, scale, and reliability.

Summary Table:

| Feature | MPCVD Method | DC-PJ CVD Method |

|---|---|---|

| Plasma Generation | Electrode-less microwave field | Direct current arc with electrodes |

| Stability | High, no arcing or flame failure | Low, prone to instability |

| Purity | High, no electrode contamination | Lower, risk of metallic impurities |

| Scalability | Excellent for large-area diamonds | Limited by localized plasma |

| Process Control | Precise and reproducible | Less consistent |

| Ideal For | High-quality single crystals, electronics, optics | Simpler setups with lower initial cost |

Unlock the full potential of your diamond synthesis with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with cutting-edge options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering superior process stability, purity, and scalability for high-quality diamond growth.

Ready to enhance your lab's efficiency and achieve reliable results? Contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What mechanical parts need regular inspection in MPCVD equipment? Ensure Process Reliability and Prevent Downtime

- What role does MPCVD play in optical applications? Enabling Next-Generation Diamond Optics

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- What effect does the sample base position have in an MPCVD device? Master Plasma Control for Optimal Deposition

- How does pressure affect the MPCVD growth process? Master Plasma Control for Superior Film Quality

- How can the growth rate of diamond be accelerated in the MPCVD method? Boost Growth with Higher Power & Pressure