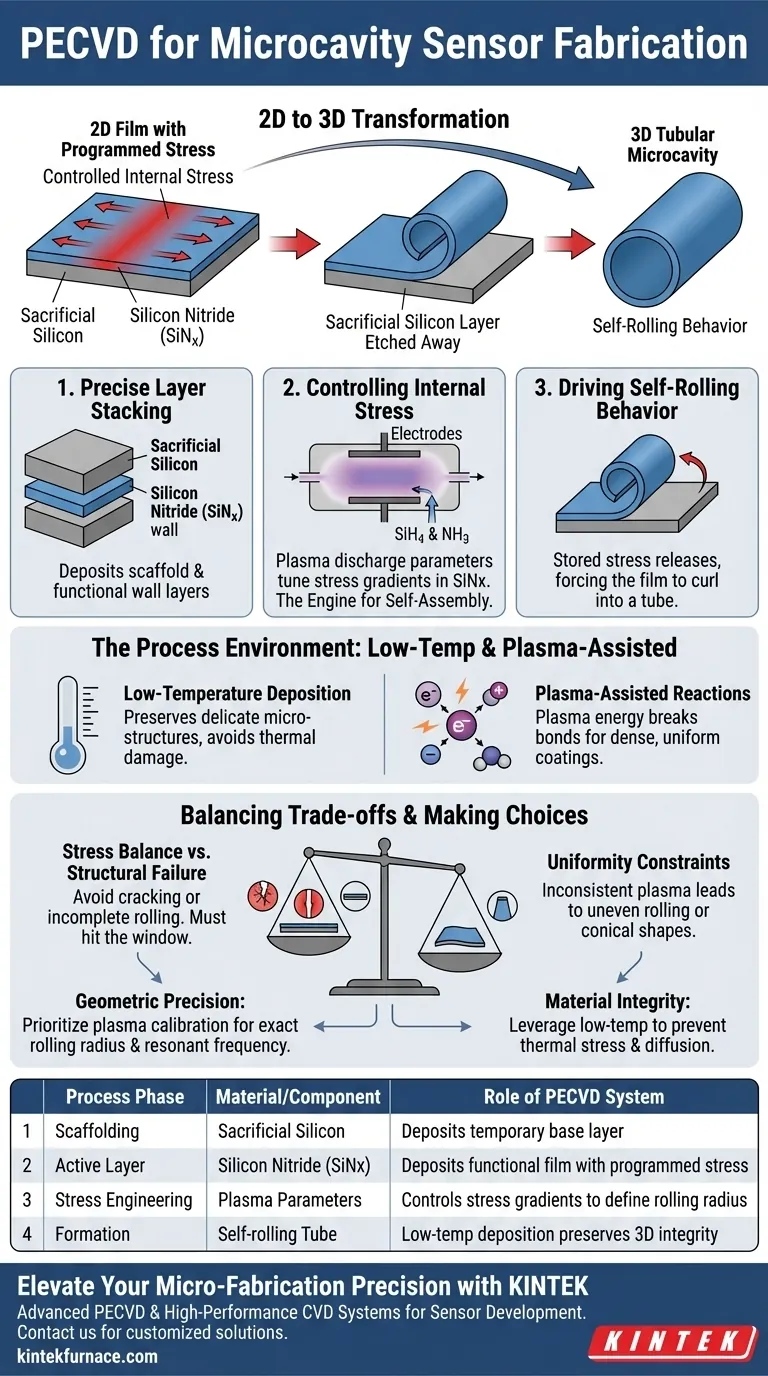

In the preparation of microcavity sensors, Plasma Enhanced Chemical Vapor Deposition (PECVD) serves as the primary fabrication method for defining the sensor's 3D architecture. It is utilized to deposit a precise multi-layer stack, specifically consisting of a sacrificial silicon layer followed by a functional Silicon Nitride (SiNx) layer.

Core Insight: The utility of PECVD extends beyond simple material deposition; it is a tool for mechanical engineering on a microscopic scale. By manipulating plasma parameters, the system induces a specific internal stress within the film. This stress is the "engine" that forces the flat material to self-assemble into a tubular microcavity once the sacrificial layer is removed.

The Mechanism of Microcavity Formation

The production of these sensors relies on transforming a 2D film into a 3D structure. PECVD is the critical enabler of this transformation through three specific functions.

Precise Layer Stacking

The system first deposits a sacrificial silicon layer onto the substrate. This layer acts as a temporary scaffold that will be chemically removed later in the process.

Immediately following this, a Silicon Nitride (SiNx) layer is deposited on top. This top layer eventually becomes the wall of the microcavity sensor.

Controlling Internal Stress

This is the most critical function of the PECVD system in this context. By adjusting the plasma discharge parameters, engineers can fine-tune the residual stress within the Silicon Nitride layer.

The goal is not a neutral, stress-free coating. Instead, the process is deliberately tuned to create a controlled mismatch in stress gradients across the film's thickness.

Driving Self-Rolling Behavior

Once the deposition is complete, the underlying sacrificial silicon layer is etched away. Because the Silicon Nitride layer holds the internal stress engineered by the PECVD process, it releases this energy mechanically.

Upon release, the micro-thin film undergoes self-rolling behavior. It curls up to form the desired tubular microcavity structure, driven entirely by the stress properties defined during the PECVD phase.

The Process Environment

To achieve the precision required for microcavity sensors, the PECVD system leverages specific operational advantages over standard thermal deposition.

Low-Temperature Deposition

Standard Chemical Vapor Deposition often requires high heat, which can damage delicate micro-structures. PECVD operates at significantly lower substrate temperatures.

The energy required to break chemical bonds is supplied by the plasma rather than heat. This preserves the structural integrity of the underlying layers while ensuring high-quality film formation.

Plasma-Assisted Reactions

The process takes place in a vacuum chamber using precursor gases like silane (SiH4) and ammonia (NH3).

Parallel electrodes generate a radio frequency or DC discharge to ionize these gases into a plasma. These energized ions bind efficiently to the surface, allowing for dense, uniform coatings even at lower temperatures.

Understanding the Trade-offs

While PECVD is essential for creating these sensors, the process requires careful management of specific variables to avoid failure.

Stress Balance vs. Structural Failure

The "stress engineering" capability is a double-edged sword. If the stress induced by the plasma is too high, the film may crack or shatter upon release.

Conversely, if the stress is too low, the film will not generate enough force to roll into a tube. The plasma parameters must be hit within a very tight window to ensure the rolling radius matches the sensor design.

Uniformity Constraints

Inconsistencies in the plasma field can lead to non-uniform film thickness or uneven stress distribution.

If the stress is not uniform across the wafer, the resulting microcavities may roll unevenly or form conical shapes rather than perfect tubes, compromising sensor performance.

Making the Right Choice for Your Project

The application of PECVD depends heavily on the specific requirements of your microcavity design.

- If your primary focus is Geometric Precision: Prioritize the calibration of plasma discharge parameters to ensure the internal stress gradient yields the exact rolling radius required for your target resonant frequency.

- If your primary focus is Material Integrity: Leverage the low-temperature capabilities of PECVD to prevent thermal stress or diffusion between the sacrificial silicon and the active Silicon Nitride layers.

Ultimately, success in fabricating microcavity sensors relies on treating the PECVD system not just as a coating tool, but as a means to program mechanical potential energy into the material itself.

Summary Table:

| Process Phase | Material/Component | Role of PECVD System |

|---|---|---|

| 1. Scaffolding | Sacrificial Silicon | Deposits temporary base layer for chemical removal |

| 2. Active Layer | Silicon Nitride (SiNx) | Deposits functional film with programmed internal stress |

| 3. Stress Engineering | Plasma Parameters | Controls stress gradients to define the rolling radius |

| 4. Formation | Self-rolling Tube | Low-temp deposition preserves 3D structural integrity |

Elevate Your Micro-Fabrication Precision with KINTEK

Unlock the full potential of your research with KINTEK’s advanced PECVD technology. Backed by expert R&D and world-class manufacturing, we provide high-performance CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces specifically engineered for the rigorous demands of microcavity sensor development.

Whether you need customized plasma parameters for precise stress engineering or specialized lab high-temperature equipment, our systems are fully adaptable to your unique specifications. Contact us today to speak with a technical expert and see how KINTEK can help you program mechanical excellence into your next-generation materials.

Visual Guide

References

- Chi Pang, Libo Ma. Optical Whispering‐Gallery Mode as a Fingerprint of Magnetic Ordering in Van der Waals Layered CrSBr. DOI: 10.1002/adfm.202505275

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the key advantages of PECVD compared to LPCVD? Lower Temperatures, Faster Deposition, and More

- What are the disadvantages of direct PECVD reactors? Avoid Substrate Damage and Contamination

- What are the temperature advantages of PECVD compared to LPCVD? Lower Heat for Better Results

- How is PECVD used in solar cell manufacturing? Boost Efficiency with Thin Film Deposition

- What is the critical application of PECVD equipment in passivated contact solar cells? Boosting Efficiency with Precision

- What are the advantages of PECVD for preparing 2D materials? Unlock Scalable, Low-Temp Fabrication

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What is the role of RF power in PECVD? Optimize Film Deposition and Quality