In Plasma-Enhanced Chemical Vapor Deposition (PECVD), RF power is the engine that drives the entire process. Its primary role is to energize the reactant gases into a plasma state, creating the reactive species necessary for film growth. The specific power level and frequency you choose are critical control levers that directly determine the deposition rate, film quality, internal stress, and step coverage.

Manipulating RF power is not just about turning a knob; it is a strategic choice between deposition speed and film quality. Higher power generally increases deposition rate and film density, while the chosen frequency dictates the balance between the chemical reaction and physical ion bombardment.

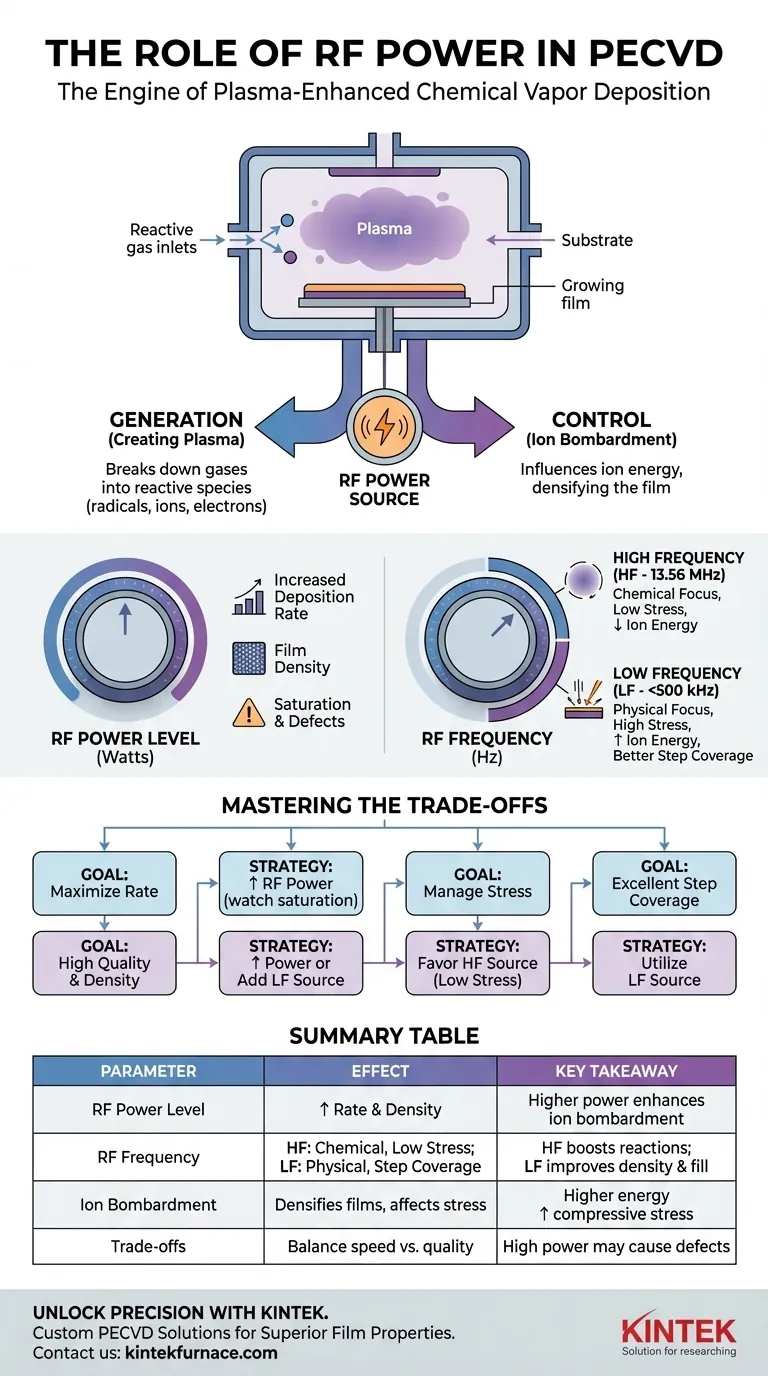

The Dual Roles of RF Power: Generation and Control

RF power serves two fundamental purposes in a PECVD chamber. Understanding both is key to controlling your deposition process.

Creating the Plasma (Gas Dissociation)

The first and most essential role of RF power is to break down stable reactant gases. The applied RF field transfers energy to the gas, stripping electrons from atoms and molecules and creating a mix of ions, electrons, and highly reactive free radicals. These radicals are the primary building blocks for the deposited film.

Influencing Ion Energy (Bombardment)

Beyond simply creating the plasma, RF power also dictates the energy with which ions strike the substrate surface. This ion bombardment plays a crucial physical role, densifying the growing film and modifying its properties.

How Power and Frequency Dictate Film Properties

The effects of RF power are nuanced and depend heavily on both the power level (in Watts) and the frequency (in Hz).

The Link Between Power and Deposition Rate

Increasing RF power generally enhances the concentration of free radicals within the plasma. More radicals available for reaction at the substrate surface directly leads to a higher deposition rate. However, this effect has a limit. At a certain point, the reactant gas becomes fully ionized, and the concentration of radicals saturates. Increasing power beyond this point yields no further increase in deposition rate.

Improving Film Quality Through Bombardment

A higher RF power level also increases the energy of the ions bombarding the film as it grows. This energetic bombardment can improve film quality by making it denser and more compact. It effectively "hammers" the deposited atoms into a more ordered and robust structure.

The Critical Role of Frequency

The choice of RF frequency fundamentally changes the nature of the plasma and the resulting film. Most systems use a high frequency, a low frequency, or a mix of both.

-

High Frequency (HF): Typically set at 13.56 MHz, HF power is highly efficient at creating a dense plasma with a large population of free radicals. It drives the chemical aspect of the deposition. Ion bombardment energy is relatively low, which is often beneficial for minimizing film stress.

-

Low Frequency (LF): Usually below 500 kHz, LF power significantly increases the energy of ion bombardment. Because the electric field reverses more slowly, heavier ions have more time to accelerate toward the substrate. This drives the physical aspect of the deposition, leading to denser films and improved fill in high-aspect-ratio features.

Understanding the Trade-offs

Optimizing a PECVD process requires balancing competing factors. Manipulating RF power and frequency always involves trade-offs.

The Rate vs. Quality Compromise

While higher power increases the deposition rate, excessively high ion bombardment can cause damage to the substrate or the growing film, potentially degrading electrical properties or creating defects.

Impact on Film Stress

The energy of ion bombardment directly influences the film's internal stress. The high-energy bombardment from an LF source often increases compressive stress. In contrast, the gentler HF source typically results in lower stress, making it a better choice for stress-sensitive applications.

Step Coverage and Topography

For depositing films into deep trenches or over complex topography, an LF source is superior. The highly energetic and directional ions can reach the bottom of features, ensuring good material coverage and preventing the formation of voids. HF deposition is less directional and can lead to "bread-loafing," where the opening of a feature closes before it is fully filled.

The Interplay with Pressure

RF power does not act in a vacuum. Chamber pressure is a critical related parameter. Lowering the pressure increases the mean free path of particles, meaning ions can travel further without collisions. This makes ion bombardment more energetic and directional, amplifying the effects of the applied RF power.

Selecting the Right RF Strategy for Your Film

Your optimal RF settings depend entirely on the desired characteristics of your final film.

- If your primary focus is maximizing deposition rate: Use higher RF power to increase the concentration of reactive free radicals, but be aware of the saturation point where no further gains are made.

- If your primary focus is achieving high film quality and density: Increase the power level to enhance ion bombardment energy, or add a low-frequency (LF) source to the process.

- If your primary focus is managing film stress: Favor a high-frequency (HF) source, as its lower ion energy typically results in lower compressive stress compared to an LF source.

- If your primary focus is excellent step coverage in trenches: Utilize a low-frequency (LF) source to promote the highly directional and energetic ion bombardment needed to fill features without creating voids.

Ultimately, mastering RF power is about understanding and deliberately balancing the chemical and physical pathways of plasma deposition to achieve your specific goal.

Summary Table:

| Parameter | Effect on PECVD Process |

|---|---|

| RF Power Level | Increases deposition rate and film density; higher power enhances ion bombardment |

| RF Frequency | High frequency (13.56 MHz) boosts chemical reactions with low stress; low frequency (<500 kHz) improves step coverage and density |

| Ion Bombardment | Densifies films and affects internal stress; higher energy increases compressive stress |

| Trade-offs | Balance between deposition speed and film quality; high power may cause defects |

Unlock Precision in Your PECVD Processes with KINTEK

Struggling to achieve the perfect film properties in your lab? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems, tailored to meet your unique experimental needs. With our exceptional R&D and in-house manufacturing, we offer deep customization to optimize RF power settings for superior deposition rates, film density, and step coverage.

Let us help you enhance your research and production efficiency. Contact us today to discuss how our solutions can drive your success!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties