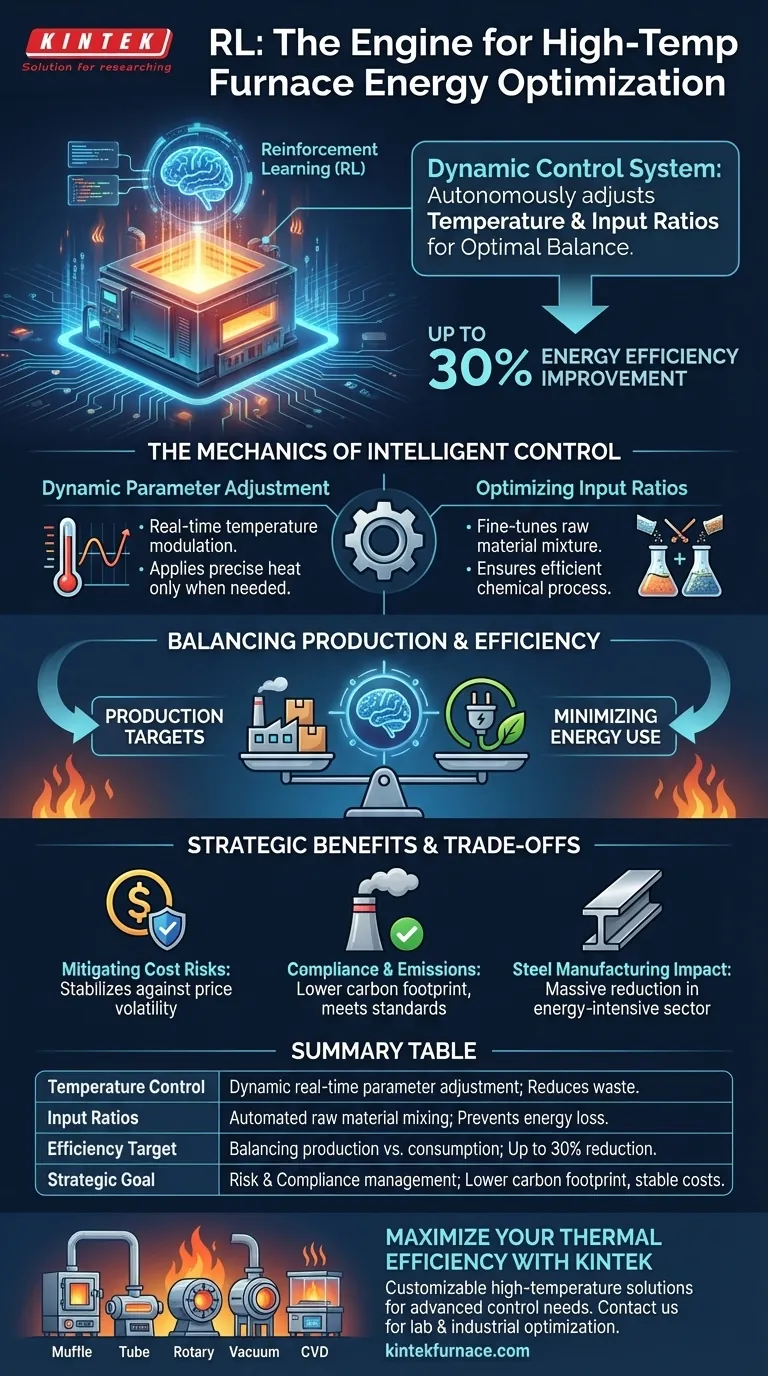

Reinforcement Learning (RL) optimizes energy consumption by functioning as a dynamic control system that autonomously adjusts heating furnace temperature parameters and raw material input ratios. Rather than relying on static setpoints, the system continuously modulates these variables to achieve the optimal balance between meeting strict production targets and minimizing energy usage.

By replacing static control methods with dynamic strategies, RL can improve the energy efficiency of high-temperature furnaces by up to 30%, simultaneously reducing operational costs and aiding in environmental compliance.

The Mechanics of Intelligent Control

Dynamic Parameter Adjustment

Traditional control systems often rely on fixed rules. In contrast, RL algorithms optimize equipment by dynamically adjusting heating furnace temperature parameters in real-time.

This allows the system to respond immediately to fluctuations in the environment or the equipment state. The goal is to apply only the precise amount of heat required at any given moment.

Optimizing Input Ratios

Beyond temperature, these systems also control raw material input ratios.

By fine-tuning the mixture of ingredients feeding the furnace, the RL agent ensures the chemical process remains efficient. This prevents energy waste associated with processing suboptimal mixtures or correcting production errors later.

Balancing Production and Efficiency

The Dual Objective

The core challenge in manufacturing is not just saving power, but doing so without slowing down the line.

The RL system seeks an optimal balance between two competing goals: meeting production targets and minimizing energy use. It ensures that energy conservation measures never compromise the required output volume or quality.

Impact on Steel Manufacturing

This technology is particularly potent in the steel industry, where high-temperature furnaces are standard.

In this context, intelligent control strategies have demonstrated the ability to improve energy efficiency by up to 30%. This is a massive reduction for energy-intensive operations.

Strategic Benefits and Trade-offs

Mitigating Cost Risks

Energy prices are volatile and constitute a major portion of operational expenses in heavy manufacturing.

By significantly reducing consumption, RL helps mitigate energy cost risks. This provides a buffer against fluctuating utility rates, stabilizing the bottom line.

Compliance and Emissions

Efficiency is directly tied to carbon footprint.

Optimizing the furnace operations helps facilities comply with environmental emission standards. Using less energy to produce the same amount of steel results in lower overall emissions.

Implementation Considerations

While the benefits are clear, implementing RL is not a passive upgrade.

It requires a shift from fixed operational protocols to trusting an algorithmic approach. The system relies on the availability of accurate data to make its dynamic adjustments effectively.

Assessing Fit for Your Operations

To determine if Reinforcement Learning is the right approach for your facility, consider your primary objectives:

- If your primary focus is Cost Reduction: Implement RL to target the potential 30% efficiency gain by allowing the system to dynamically manage raw material ratios and temperature.

- If your primary focus is Regulatory Compliance: Leverage the system's ability to minimize energy use to directly lower your facility's carbon footprint and meet strict emission standards.

Success in energy optimization comes from allowing intelligent systems to manage the complex trade-off between raw input, temperature control, and production speed.

Summary Table:

| Optimization Pillar | Control Mechanism | Key Benefit |

|---|---|---|

| Temperature Control | Dynamic real-time parameter adjustment | Reduces waste by applying precise heat levels |

| Input Ratios | Automated raw material mixing | Prevents energy loss from suboptimal processing |

| Efficiency Target | Balancing production vs. consumption | Up to 30% reduction in energy usage |

| Strategic Goal | Risk & Compliance management | Lower carbon footprint and stabilized utility costs |

Maximize Your Thermal Efficiency with KINTEK

Ready to transition from static heating protocols to high-performance, intelligent operations? KINTEK empowers lab and industrial facilities with cutting-edge thermal solutions. Backed by expert R&D and precision manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temperature furnaces—all fully customizable to integrate with your advanced control needs.

Whether you are looking to mitigate energy cost risks or ensure environmental compliance, our systems provide the stability and precision required for Reinforcement Learning optimization. Contact KINTEK today to discuss how our customizable high-temperature solutions can revolutionize your energy efficiency and production output.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the controlled environment of a vacuum furnace benefit material processing? Enhance Purity and Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does vacuum or protective atmosphere melting improve the quality of aerospace materials? Achieve Superior Purity and Performance

- Why is an electric heating oven required for laser cladding pre-treatment? Ensure High-Density AlxCoCrCuyFeNi Coatings

- Why are ZrO₂ ceramic blocks utilized as auxiliary fixtures during the vacuum brazing of TC4 titanium alloys?

- What role do vacuum sintering furnaces play in additive manufacturing? Transform 3D Prints into Dense, High-Performance Parts

- In what way does a Spark Plasma Sintering (SPS) system inhibit grain growth? Achieve Precision Nanostructures

- What technical requirements must a furnace meet for Inconel 718 hardening? Master Precision Aging & Cooling